Can somebody please tell me how do you get a hold of support. I have an issue that I would like to get resolved without having to email and text back-and-forth and let it take all day. I need to speak to a person so I can get this issue resolved, does anybody know how to get them to answer the phone?

I’m afraid sending an email is the best way … You could also try posting your issue here and see what help you may get. Lots of folks here may be able to help.

Anthony

If you leave a message it’s transcribed into a ticket in our queue and then we handle the tickets in the order they come in. Your ticket has already been tagged as a new machine so they’ll get back to you more quickly.

Maybe we’ll get back to the day that we can pickup the phone in real time, but, in the past, that just led to a relatively small number of folks calling nonstop all day long and starving out the rest of the queue.

Get caller ID and know which ones to ignore ![]()

Maybe you allow 1 call per week.

What is the issue, do you think someone on the Forum could help? Details if you think so.

So my machine is ashapeoko pro less than 30 days old. I am having a problem with erratic X movement. When it moves from left to right and right to left it does not move smoothly it jumps and stalls. I have checked the tension on the belt. I have clean the tracks really well with a Toothbrush. I have oiled all the tracks And still the same thing. I have used different files with no change in results.

I also removed the X motor to check the gears and in my novice opinion they look good, but the motor moves really rough when you turn at my hand.

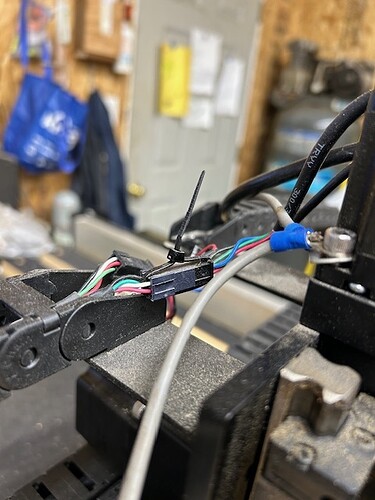

Before support gets to you try looking at your wiring. Any plugs should not have any heat marks and push in on both ends of the wires to make sure they have a good connection. Sounds like the X motor is maybe not running all the steps it should. So you get the jerky motion. To help with the connections move your gantry back and forth (jog) 7-8 times and then feel the connectors for a heat buildup. Heat indicates a poor connection and the by product is heat and loss of steps.

It’s almost bedtime where I’m at, so I will take a look at it in the morning. Thank you so much.

It sounds like the motor spine is slipping on the belt. I have checked the tension and reset it, but I still get the same results. In the morning, I’m a pull the motor off and make sure that the motor spine set screw is tight.

It looks like Oscar requested a short video of the homing process a few hours ago. Before you spend time taking anything apart, shoot that over to him so he can see if there’s something obvious to correct.

So this morning I went out to the shop and that is you said. I took the wire Connectors apart and reconnected them pushing in from both sides and pushing in on the wires. Woo hoo I think that may have fixed my problem. I ran the gantry back and forth Many times no heat in the wires no skipping or erratic motions. Made some chips with both slow and fast Feed rates and I had no problem. Thank you so much for your time.

I think I have resolved my problems to a loose wire.

Thank you.

Be sure to zip tie & secure the wiring connectors of the stepper motors. They are notorious for causing issues due to intermittent loss of connection during operation from vibration & strain as the harness moves with the gantry.

Also ensure that dust collection vac hose cannot contact the wiring harness connectors.

You can ignore the last message the troubleshooting I did this morning did not resolve the problem. About halfway through a project I was cutting this morning the X axis started jumping and moving erratic again it really sounds like the belt is slipping. I adjusted the belt yesterday and again this morning and it is still doing the same thing. It’s like it’s not getting left traction when pressure is put against it then once it slips it loses its coordinates of what is the X and Y 0 and just screws everything up. Please help me fix this I am getting very discouraged.

To really test the stepper motor connectors, jog the axis along while fiddling/twisting/bending the motor connector a bit by hand. I’m mainly referring to X & Z axis’s here as I’ve yet to encounter any major issue with my Y axis motors - a bad Y-axis motor or connection would quickly cause the gantry to twist & bind so it’s sort of self-testing.

If the axis stutters/grinds/skips while doing this, there is a good bet that is the problem. Intermittent electrical connections are the bane of any control system because they can be seemingly fine & then throw a wrench into things at random moments with no apparent cause.

If the problem is not the connectors or wiring, then the next thing in-line which could cause the problem you’re describing is a bad controller board which would need to be replaced.

Does the skipping happen in the same spot along the X beam? Any chance you have some broken of missing teeth on the X belt?

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.