Minimizing the overall cutter stick-out from the structural supports can also help. If the MDF spoil-board is adequately secured and supported it’s not likely an issue (in most/all situations) IMO. That’s especially likely in this situation where the axial forces are likely insignificant and there’s less axial cutting force with the deep cuts than the shallow ones. Linear rails are an entirely different story.

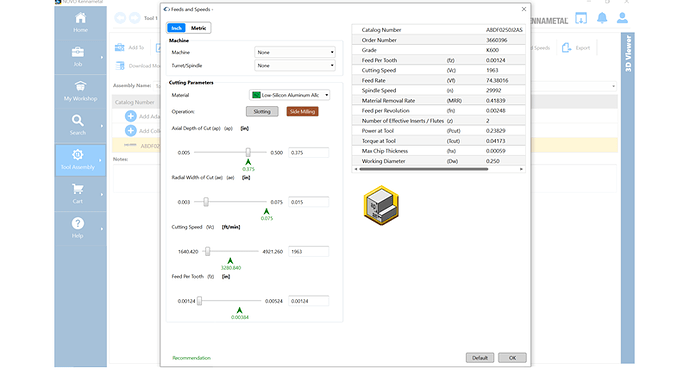

I’m a recovering(?) engineer, so my inclination would be use endmills (and other tools) within the parameters established by their manufacturers. Kennametal makes affordable endmills that might be worth considering. Here’s what their recommendations (adjusted for Shapeoko limitations) are for @Kai’s project.

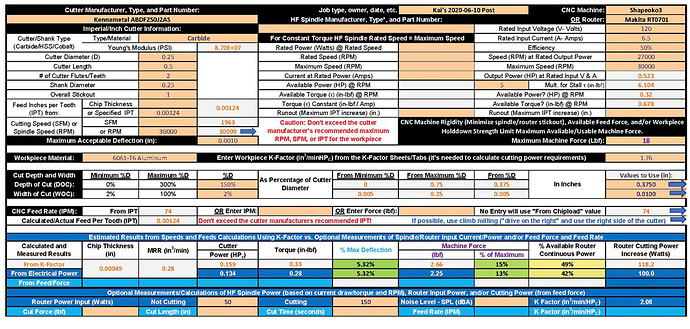

Their K-Factor is apparently 1.76 cuin/min/HP vs. the SPDF’s 3.344 (more accurate?), so I changed that as shown here:

Note that there are cutting power, torque, and force increases to achieve the same MRR.

The latest SPDF Workbook with sheets for this stuff is contained in this compressed folder: 2020-06-10 SFPF.zip (174.7 KB)

I’m still trying to figure out how to rate your BLDC motor’s capability, so that’s likely to change. Also @LiamN has been helping to get more accurate parameters for HF spindles, so that’s likely to change too, as will the AC router parameters and the “Measured K-Factors”.