It’s not fully airtight. The bypass doors and a few other sections use brush style threshold insulation so plenty of air seeps in through it and the volume is pretty large in there. The dust collector has no issues and doesn’t work particularly hard. I could get it quieter by using more airtight seals but it’s not bothersome now with the setup as it is, adding sound dampening panels to the back wall and ceiling helped too. I can have a conversation outside the doors without raising my voice so for me at least it’s good enough to allow me to move on to other projects. If Id decided to seal it tighter I was going to put a vent from an acoustic dampening chamber on the roof but after testing I didn’t think I needed it.

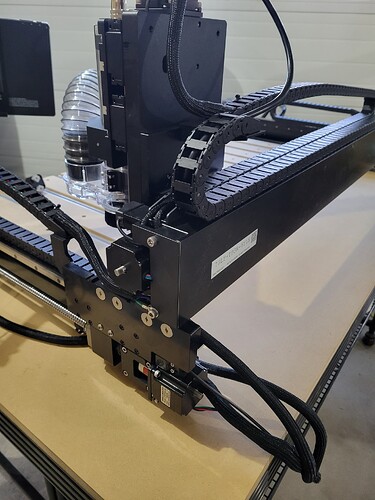

I finished building my table and machine and I want to show it off. I cobbled the table together using black wire shelving components for the base. I have a lot of it in my shop, so looks on point. It is 2 sections of 18" x 60" joined back to back.

The frame for the top is linear rail extrusions and hardware from Openbuilds. I selected that because I had an idea for vertical workholding that I had to bring to fruition.

The t-bolt access slots were milled by a buddy of mine. I expect to find additional accessories that will use them, but for now it is just those clamps. I have some project ideas that will be challenging for a newb like me.

I needed drawers, and looked to my tool chest for inspiration. Sadly, I couldn’t find an intermediate box in black, but red will do.

I tidied up the wiring, but had to drive back to work (oilfield) before I could finish. And I failed to get a pic of the dust collection hose setup, but maybe another time.

For now I an excited to have the machine up and running. I’ll be cutting stuff at Christmas

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.