I have a problem with my shapeoko 3 xxl drooping in the middle of my spoilboard. I face the spoilboard at 1 height and go to put my square lines on it and in the middle the lines dont get cut in. The center of my spoilboard is a full 1/16th lower than the outside. I have tried this 3 seperate times and always the same result. And as you know making a spoilbboard is a time consuming process. The spoilboard is fully fastened and does not flex or move. This is being caused by a droop in the center of my x axis.

Well, yes. The XL has the same problem, it does droop a a couple thousandths in the middle. Not sure what you’re asking for. It’s worse if there is weight on the table. You can block/shim underneath it. If it’s really a big problem, that’s where the torsion boxes come in, but that’s a somewhat bigger task.

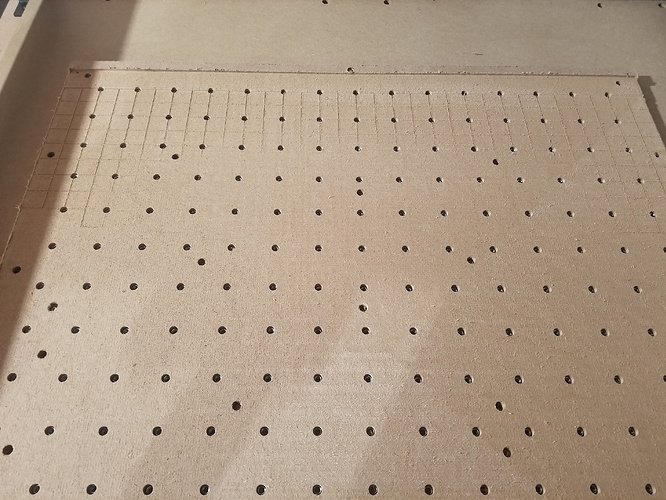

I paid 1800 dollars for this thing and it cant even do the simple v carve i need it to do! 20180821_185411|374x500

This is a simple job and it looks crappy. I bought rhis to make signs and all my v carves look great on 1 side and crappy on the other. I cant even give these things away as gifts with the quality its putting out

Well, from the picture I see that it’s also not square to the Y axis (front to back) - that requires some work with adjusting the side rails to get correct.

If you’ve already given the wasteboard a surfacing pass to square it to the router (it looks like you did?) then there really isn’t any reason I can think of for it to be out of alignment. If you have sag in the middle, that will be essentially milled out by surfacing the wasteboard. If it was surfaced, then not being able to put the lines in indicates something in the machine is moving, and that just shouldn’t be happening. Are you absolutely sure that all the fasteners with rails to the end plates, and all of the fasteners between the lower wasteboard and the frame are solid?

You seem like the kind of person who would order a plain single hamburger because it was $4.00 and then complain to the server about how it doesn’t have extra meat, bacon and cheese because you didn’t want to pay $8.00 for the double deluxe burger.

If it droops, shim it.

If it is loose, tighten it up.

If it is out of square, true it up.

If you want to know how to do something, ask. We’ll help you as best we can. Don’t come here just to complain.

Is the stock the same thickness on both sides?

I don’t understand why after you surfaced the waste-board this would be occurring otherwise. I spent some time squaring my entire machine and then put down a sacrificial waste-board and face it to finalize everything and it is excellent results. I think I used Winston Moy’s video on YouTube as my baseline for squaring.

I would make sure everything is square and tight then surface the waste-board again.

Good Luck!

Just ensure the waste-board is supported underneath then re-surface. Job done.

Unfortunately, the machines have to be something of a compromise — they’re built to be as good as they can be, at the lowest price point which makes sense. The long unsupported span on the XL and XXL is workable for most folks, but on some machines, for some folks is problematic.

Any of the suggestions above are valid and workable — which reminds me, I need to further improve my setup by drilling mounting holes in the plywood I have mine on so that the machine is fully supported along the bottom so that it doesn’t deflect if I clamp things at the front of the machine. (Next step is getting a second sheet of plywood and making a torsion box).

I had the same issue with my xxl. I removed the feet and sat mine on a 3/4" sheet of plywood, I can now put 200lbs on the middle of the wasteboard with no deflection. easy fix.

I removed the feet and added a 1" Mdf spoil board on my Xxl,that helped alot to stiffen things up.

Removed the “leveling” feet, dropped it onto a rubber mat atop a thick plywood top, shimmed where needed, added additional waste board and surfaced the spoilboard. Flat, very flat and no sag now.

You can see my journey to flatness here:

Dan

I will try taking the feet off and putting it straight on my mdf table i made for it. It will have to wait till after the weekend since just facing my spoilboard takes 5 hours. I will go through every bolt and retighten if needed.

And i bought this to do one job, thats it. Im not milling aluminum or anything crazy i just need great looking v carves and i choose the most robult cnc machine i could to do that.

I will also take apart my x axis and see if the aluminum was bent and could be the source of my problems. I have a feeling that that is the problem and i just have no way of telling till i take it apart.

Please check you feed / speed rate for surfacing the wasteboard — shouldn’t take much more than a few minutes, even w/ a 1/4" endmill.

Interesting. I haven’t resurfaced mine yet, but need to. I bought a 1/2" surfacing bit to do that job. What feed/speed is recommended for resurfacing?

Since it’s a skim cut (0.1mm is a useful amount to take off in most instances) one can go as quickly as one can while still getting a decent chipload.

For cutting wood I have not experienced any issues with droop on my XL.

I would ensure that your cutting surface is machine parallel to endmill. This means tramming the spindle and surfacing a spoil board.

I often get a sacrificial piece of flat board that is quite dense (Triboard/OSB) and use hold downs to clamp this to the wasteboard. I surface a large portion of this down so that is machine leveled. Then ontop of this I use masking tape and CA glue to hold my stock down. If I was doing a carving or engraving I would machine flat BOTH sides of my stock. Then after surface machining the second side I would start my engraving. I have achieved very satisfactory results down to 0.1mm and better.

I did some aluminium engravings for some coasters over an A3 sheet of aluminium and had no problems at 0.1-0.2 mm depths.

Also I would take off a bulk of work then do a 0.1-0.2mm finishing pass and a spring pass if I am after some very accurate work.

Here is a picture of my usual setup for work requiring more accuracy:

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.