So I have a piece of .5” thick plywoood.

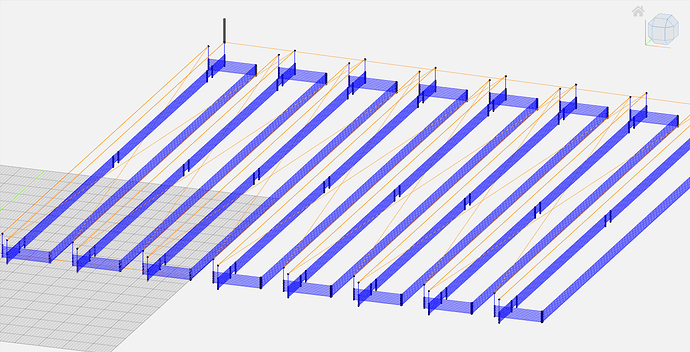

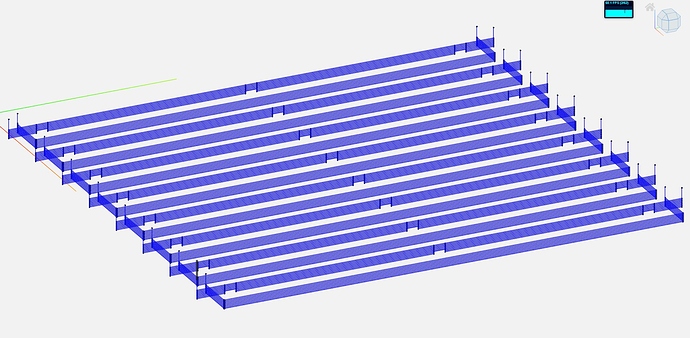

I have 8 cutting paths to cut 8 parallel slots.

In the same single tool path in carbide create.

I’m on a Mac.

The first 3 slots cut as programmed to .51“

The last 4 cut about half way to the programmed depth, then move on to the next slot and cut shallow. Like the exact same 1/4” shallow. Following the correct tool path.

Doesn’t seem to be a hardware problem. I have the probe and the bit setter.

Does this over and over. Even after I go in and reset the max cutting depth numbers, restart, reset etc.

I now seek advice from learned members of the forum. I’m stumped.

Hi @Ruralist,

could you upload here the G-code file (.nc) you are running, for a check ?

What kind of Z axis do you have on your XXL ?

It’s toolpath 2.

Thanks

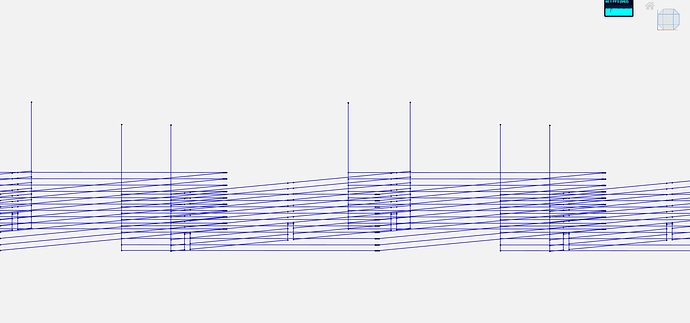

The G-code is ok, it should cut 8 identical slots indeed.

A possibility is that while cutting the last “correct” slot, Z axis looses steps, and then the Z zero reference is offset for the rest of the cut. But why this would happen, with a Z-plus, plunging at 18ipm in plywood…no idea.

You could try to run the file as an air job, see if the same weird effect happens after the 3rd slot (you should be able to see if it goes 0.5" deep or just 0.25")

Are you using a Sweepy ? if so, I would try a test run with the Sweepy raised high enough that the brushes don’t touch the surface even when cutting max depth.

Do you have a pic of the cut, in case it provides any clues ?

My gut tells me that this is a software glitch.

Maybe this program a little unstable on Mac?

I’m going to start again and rebuild this file from scratch.

Also, I haven’t yet installed the latest carbide create upgrade.

I don’t think so. The G-code file is correct, so Carbide Create did its job correctly. And then Carbide Motion (this is what you are using, right?) on Mac is being used by tens of people here with no such issues.

If you retry this cut, maybe save that 2nd part as a separate G-code file and run that only ? (to rule out an interaction with the first toolpath)

I’m on it.

Thanks so much for your input.

I have taken the G-Code you provided and simulated it in NC Viewer as well as imported it into Easel (after running it through a post-processor). I did not see anything wrong with the code or any of the simulations.

I decided to run a test with your code “as is” using a scrap piece of 1/2" plywood I had a laying around. I am using a Windows 10 machine instead of a Mac, and had consistent cut depths throughout. I am not an expert by any stretch of the imagination, but outside of something mechanical, like missed steps or a collet issue, I don’t know.

One more idea… have you checked to see that the workpiece is secure and the correct thickness? Plywood is notorious for not being the correct thickness. You can buy a 1/2" piece and get thickness variations as much as a 1/16" off.

Cutting slots as narrow as the tool is wide results in 100% tooling engagement which is not best practice — possible to rework the file and cut as a pocket? If need be, use a smaller tool?

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.