as the title says the machine is literal cutting like complete trash it has now costed me a few hundred in materials! when will they fix their solfware?

Please provide a .c2d file, generated G-Code, the specifics of which versions of Carbide Create and Carbide Motion you are using, and step-by-step notes on how you are securing your stock and setting zero relative to it, and a photo showing an attempt at cutting still in place on the machine either here or to support@carbide3d.com and we’ll do our best to work through this with you.

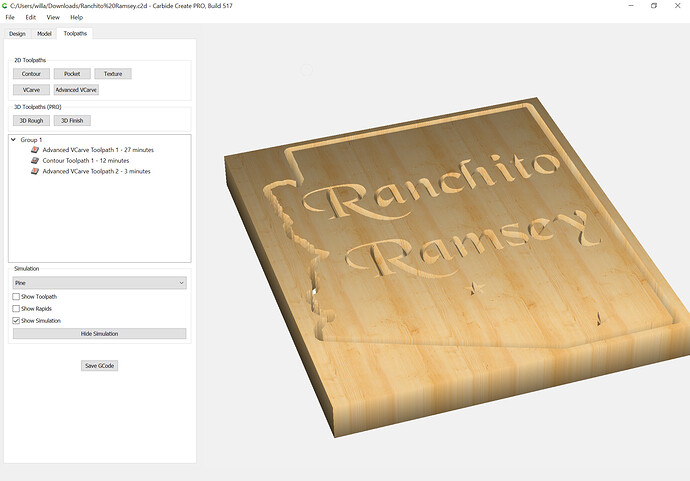

carbide create is 515 (beta version) and 535 in motion. Ranchito Ramsey.nc (575.4 KB) Ranchito Ramsey.c2d (532.1 KB)

this machine actually ran amazing before the latest batch of solfware updates. So yes I am getting irritated as hell because I have over 2500.00 into my machine and it can’t even cut letters or even 2 simple stars in advanced Vcarve.

Well why update software if current version works perfectly fine. Beta software means that it might work or it might not. Or at least save the old version to fall back to.

I was given the beta as it was suppose to actually send the codes the the machine and save them with out the issues they havnt resolved since September last year. as well it was doing the same crap performance then.

Please provide step-by-step notes on how you are securing your stock, how you are setting zero relative to it, and how you are managing the tool changes.

One thing I will note is that you are cutting a slot just as narrow as the endmill is wide — this results in near constant 100% tooling engagement, adding geometry and cutting as a pocket down to tab depth or the penultimate pass will make for smoother cutting.

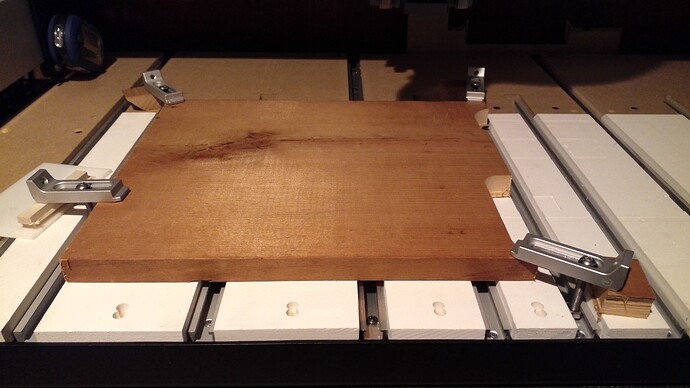

the stock is secured by 4 clamps, I use both the bit setter and bit zero to set up and setting zero. I have the zplus if that matters.

Please provide sufficient details that we can reconstruct what you are doing — where are the four clamps place? What sort are they?

Where did you place the BitZero to set the zero? Which version of BitZero do you have?

What tool was loaded initially, and when were tool changes made?

How did the cut compare to the 3D preview? (I don’t have the font you used — tracking it down now)

Could you send us a wide photo showing how the stock is mounted on the machine?

The file preview seems okay as well:

Are you sure that this isn’t a mechanical issue which coincidentally occurred when you did the software change?

Please check your machine mechanically — if everything checks out, make a very simple and small file which you can cut in a piece of scrap as requested above and I’ll cut the test piece on my machine to compare.

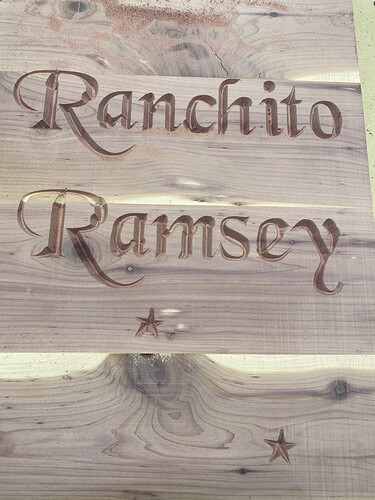

version 1 bottom left corner. the tool to set it up was the 201. the file stared with the 302. that’s how it was clamped in. the first pic you can see how messed up both the stars and letters are vs the 3d image. it got thrown hard in my junk wood bucket after seeing how messed up it is and not being able to reuse the wood to make it again.

Okay, I have a bit of scrap which will at least allow testing the first part of the cut.

Clamped at 3 corners and one edge:

the belts all are basically new the z plus is new the old one locked in the down position as would not rise up

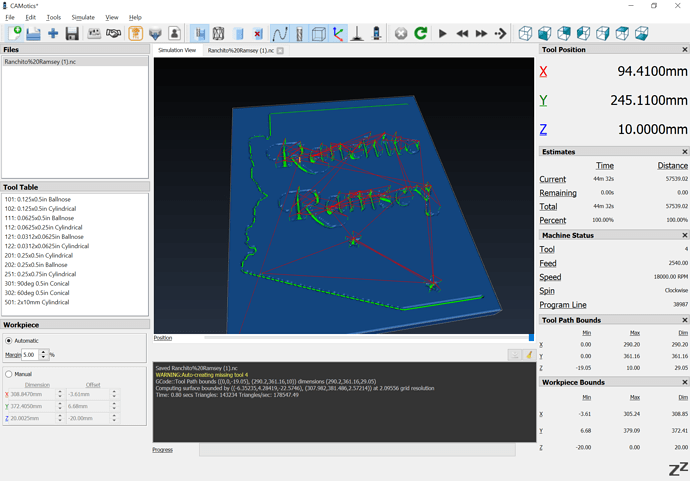

Loaded the file “Ranchito%20Ramsey.nc” from the post above which had been downloaded to my downloads folder, clicked on “Start Job”, clicked on “Start”, when prompted, loaded a #302 and clicked “Resume”, the machine began cutting.

yes yours is cutting perfect like mine use too any ideas? on mine is short cutting at times? or cutting all sorts of mess ups? as you can see with these stars it did the same thing butched a few of them while all but 4-6 are perfect.

Cut finished fine (aside from where things broke up where the wood was split or at the knot):

which should verify that the problem isn’t the software, but something mechanical with your machine — if you have trouble identifying the difficulty, let us know at support@carbide3d.com and we’ll do our best to assist.