I am working on a segmented vase as a gift for one of my woodworking club members. Dr Shows is in his 80’s and is retired and moved to Palestine Texas which is too far for him to continue in our club. Dr Shows has been a member for about 40 years and also retired from SFA. So to commemorate his years in the club I am making a segmented vase. This vase material is very special to Dr Shows. In 1925 at Stephen F Austin University (SFA) Mr Aiken built the Aiken Gymnasium on the SFA Campus. For years SFA played basketball and held social events in the gym. In the 80’s the old gym was torn down after a new modern stadium was built. Dr Shows and his father salvaged a great deal of the maple flooring from the Aiken Gym. As a woodworker Dr Shows was very frugal with wood. The wood sat in a shed since the 80’s. Since Dr Shows is moving from his long time home he offered the wood to the club members. I showed up with a trailer and filled it up.

So when the subject came up for a commiserate show of our appreciation I thought the vase made out of the maple flooring from Dr Shows lumber would be appropriate.

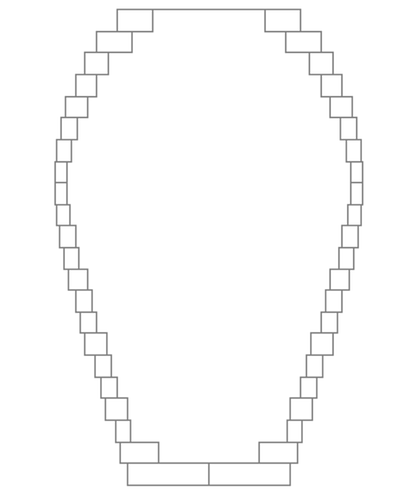

Here is the outline of the base from a program called SegCalc

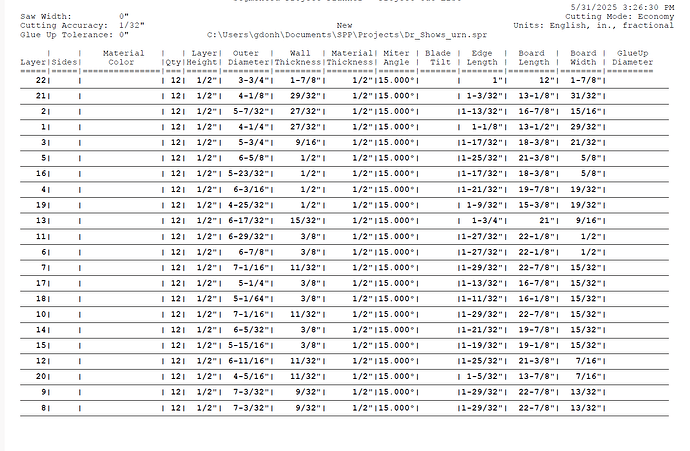

The vase has 22 layers plus I will make a top with a finial that is not pictured. The layers are about 1/2" thick. The maple flooring started out as .75" but after planning it was 1/2" thick.

The maple flooring was full of bug traces and holes. Not sure if the bugs were in it from 1925 or in the years it spent in a shed. I had to make a lot of extra material to cut out bad bug damage and there were also nail holes. Here is a picture of the flooring after a single pass through the planner.

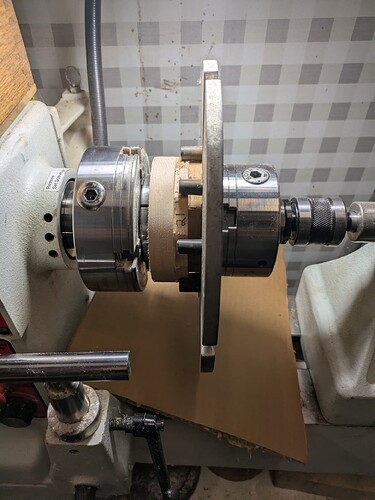

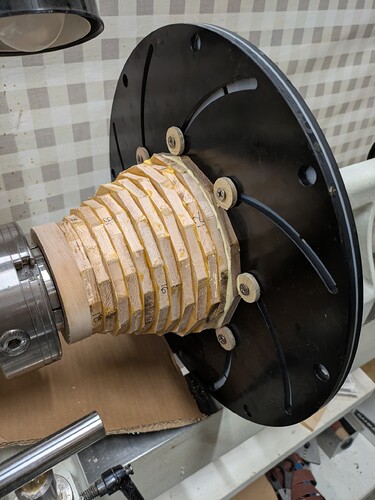

So I started assembling the vase on my lathe with what is called a Longworth chuck. It centers the segmented rows because they are rather thin and after turning they will be thinner so centering is critical. I was using my cole jaws but as the segmented layers got to similar sizes that did not work because the bumpers that hold the layers was bumping into the already glued up rows. I I decided to move over to the Longworth chuck. However that had the same problem that the bumpers were too thick. So to fix this problem I remembered I have an SO3 and designed some new bumpers out of 1/4" plywood to hold my layers up without hitting the previously glued up rows.

Here is the cole jaws with the bumpers that are too long. That worked up to a point.

So here is the longworth chuck with the hastily made bumpers out of plywood. They are short enough to not interfere with the previously glued up layers. The project only took a few minutes to design and about 10 minutes to cut. I used painters tape and super glue to hold the pieces down due to their small size tabs would have been a pain to trim off post cutting.

So what you see is layer 22-11 glued up. I will now hollow out the inside and then proceed to glue up the layers 10-1. I may glue up 10-5 and hollow again but I will make that decision on the fly. Technically the inside does not even need to be hollowed but my AR is kicking in. After the 22-1 layers are glued up and dry I will cut the entire outside at once to get a flowing design.

Additionally I will make a base and engrave the commemorative message with my SO3.

For anyone curious this is the cut list from the SegCalc program. You an see it is quite a complicated endeaver to make a segmented vase of this size.