I have been using the Deep Sweepy most of the time but I have been cutting 3.5 thk pine recently and the Deep Sweepy has been an issue at times.

I have had to adjust my hose hanging to allow for the hose to fully collapse if it gets plugged up too much. I lost two pieces recently, so I have been much more alert to the vacuum.

I am using a 6 gal Stealthsonic.

I tried the Short Sweepy and it collapses the hose due to lack of air flow.

The difference between the units is 1 sq in at the transition between inlet and outlet.

You can hear the vacuum working harder with the Short unit, as well as being louder a the spindle.

So I drilled 12 ( eye balled with one eye ) .330 diameter holes ( that was the drill currently in the drill press ) which gives me another 1.02 sq inches of are for the air.

Here is what the Short unit does to the hose if I mask off the new holes.

Here is what 10 holes did for the Short unit. I have added two since.

Here is the Deep unit.

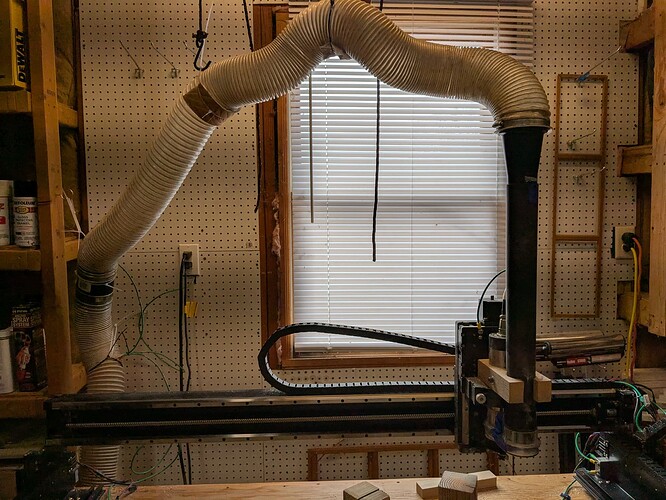

Here is no Sweepy.