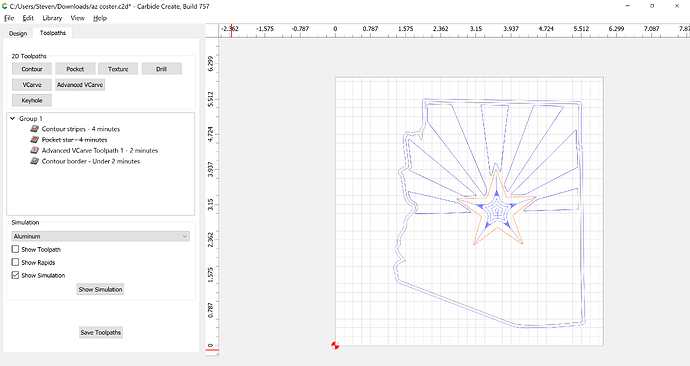

Hello again I’m working on maximizing speeds to cut while maintaining the level of precision I would like.

Is it standard practice to use the quarter inch bit to hog out the inside of a large pocket that has a lot of details around the edge and then a smaller bit to do the outer detailed parts?

If this is the way, or a good way to do this, does anyone know of an easy way to make sure all of the pocket gets cut out and no little pieces are left?

Rest machining is your path. Do you have CC Pro?

If you have islands left then you need to decrease step over. If you have the pro version of CC you can use rest machining. Rest machining uses for instance a 1/4" bit to hog the majority out and then a smaller like a 1/8" bit to get the rounded corners smaller but never square.

I don’t have pro yet, but I think I’m definitely gonna buy it.

One technique is the “pocket + contour” trick. Pocket using the larger bit, then do a corresponding Contour using the smaller bit.

So long as the smaller bit is at least half the diameter of the larger bit, then the result will be the same as if you had cleared everything using just the smaller bit.

This will do more work than true Rest Machining, but it’s a technique available in the unpaid CC.

Oooooo nice ! I bet you that’s the easiest way possible. Ty @mhotchin

Another Trick I use is to do the “hogging” out with a big stepover.

Then do a final pocket pass with a small stepover.

For Example: When I do a .5" deep pocket, my first tool path would be: .25 EM, 35 Plunge, 75 Feed Stepover .2 to start depth Zero max depth .45

Second Toolpath: .0625 Stepover start depth is .45 Max Depth is .5

You can also do use a .125" bit and do a Counour Cut to clean up the corners etc.

This topic was automatically closed after 30 days. New replies are no longer allowed.