This afternoon I needed a spindle fan solution for machining MDF and clearing out the dust. Here it is!

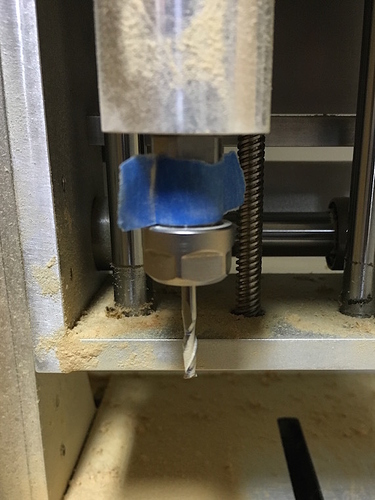

It’s just two pieces of blue painters tape (any tape will do really), adhered around the spindle to create two short flaps. The picture doesn’t show it well, but I did try to align the tabs to be more fan blade like and angle them. I don’t think it matters though. It produced enough turbulent air around the cutter that the dust was moved out and away.

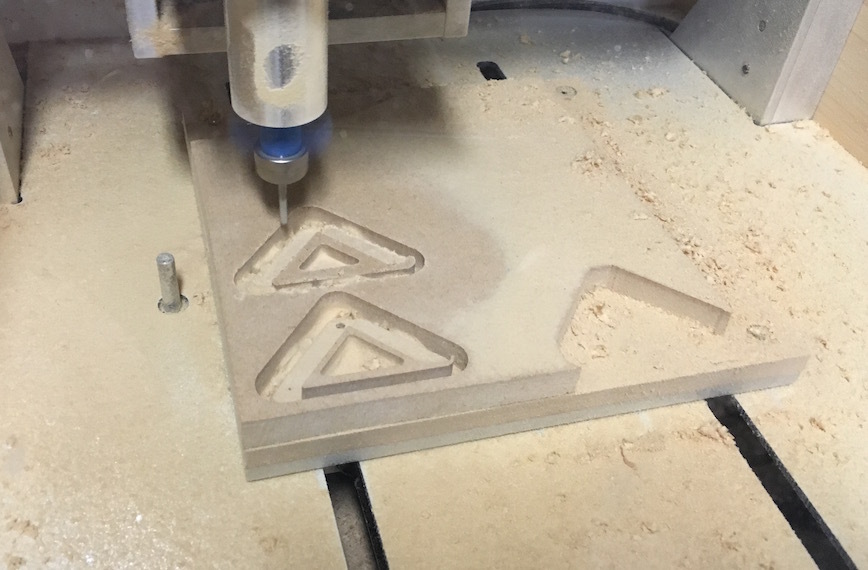

As you can see, the dust is all spewed all around the bed, but mostly clear of the job. It’s not perfect, but I would say it’s more than 90% effective. In deep ruts, the “fan” can’t get everything out, but the cutter will generally move things out enough to blow away if it gets too deep.

Just as a comparison, I machined the lower part without any fan beforehand. Anyone that has machined MDF knows that the cutter just regurgitates the dust and makes are really fine powder that’s like concrete. It all just sits there and piles up. Not good for the cutter or lungs.

So, a little background. I need to machine about 100 small MDF parts, would like to leave the machine unattended for short periods, keep the dust contained inside the Nomad, and not have to manually clean out the dust with a air compressor or brush. I have a hydroponic air pump that I use to continuously blow out chips for metal jobs and keep the tool cool, but this is too powerful and would blow dust everywhere and out into the shop.

I like the idea of spindle fan solutions, but they usually have way too much mass and are overbuilt. (I tried one once. There was too much drag on the spindle motor and doesn’t work that much better.) I hope this solution will help some people, because it’s really simple, cheap, easy-to-replace/modify, and it works.

EDIT: For lower rpm jobs, if the “fan” isn’t blowing enough, just make the flaps longer. This is something you can’t do with a fixed spindle fan.