I Had issues making a game board that I’ve made a number of times This time I had to Change the center engraving to a different name which I did using Carbide Create V7. When running the program it cut all the pockets too deep. I thought it was because I was running Carbide Motion 575. I downloaded Carbide Motion 618 and any work I do like a simple .25 hole in the middle says the project will hit the back, Front Sides and Plunge to deep. Its like it doesn’t know my work area. Tried looking for those setting and can’t find out how to do it.

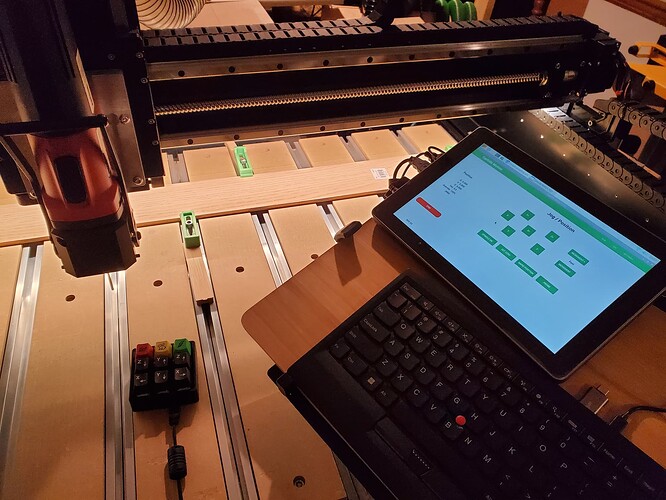

Please post your .c2d file, step-by-step notes on how you are securing your stock and setting zero relative to it and managing all tool changes and a photo showing an attempt at cutting still in place on the machine.

agg Test.c2d (52 KB)

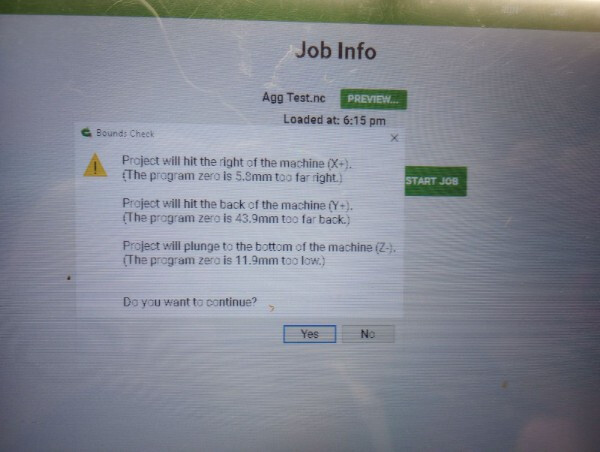

I set zero to the center of the table/waste board. When I hit start I get the warnings

Where relative to what center? Physical center? Or Rapid Position Center?

Where is your stock clamped? On the MDF itself?

Please photo showing an attempt at cutting still in place on the machine with the machine at the origin relative to it as well as a screen grab showing the warning in Carbide Motion.

I center it right down on the physical bed. Not even having any piece just the wasted board surface. When I zero it I click the set zero, done. Then when I go to load the new program it used to ask if I want this as my zero. This new download doesn’t ask me that. Here is the warning.

Please post a photo showing an attempt at cutting still in place on the machine with the machine at the origin relative to it.

And Carbide Motion shows that as the origin there?

Because the only way I can get the warning to happen is when I have the origin at machine origin.

Positioning my machine similarly and setting the origin:

I do not get an error on loading that file:

I then click done with loading the file. Then I hit the run button, and the error comes up.

How come it doesn’t do the alert asking me if this is my zero before I load the file.

After I have it home on the bitsetter and it stops above and a little left of the bit setter. Then I jog it to where my piece is, I hit the zero button then when the numbers come up I hit done. That’s the way I’ve always done the zeroing and locating the workpiece.

The error comes up when I start running the program.

This topic was automatically closed after 30 days. New replies are no longer allowed.