Oh, sorry, kjl. I misread your earlier post and thought you had just returned the stepper board.

Hi Oliver,

So far we believe it’s a subset of machines, not all machines, so shoot an email to support@carbide3d.com to get into the ticket system if you’re seeing this behavior. Hopefully we can swap out the boards and call it a day if that is in fact what you’re seeing. Try to confirm it first with a test cut (like some of those we’ve seen here with the drifting action going on) just to be sure.

-Jonathan

@oliverblum Did the new fan resolve your drifting issue? I am also experiencing a drift in the x axis on long cuts and my fan is also making weird noises periodically.

Hi,

it did not resolve the issue unfortunately. While i thought it did for a while, i just had the same issue again (see bottom of this thread: X Axis off in some carvings, especially longer ones).

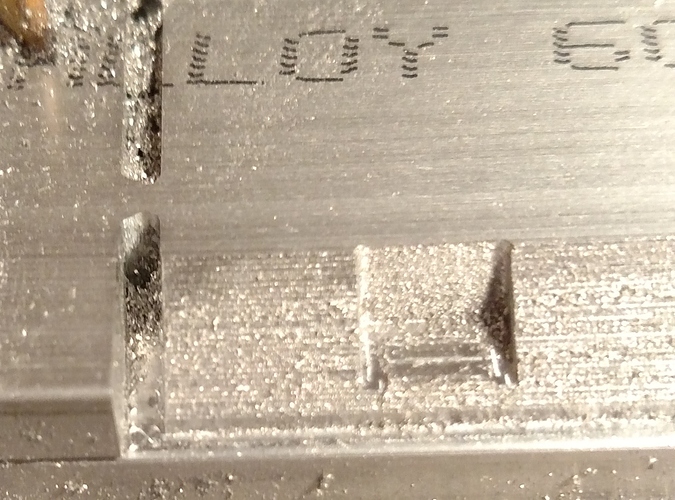

I suspect that the issue i had there was also caused by the electronics board, the ridge you see on the right side was basically the ‘leftover’ of the stock, but instead of it being straight as you would think (using #101 cutter), it is wedged towards the X axis. That carving was also a 10+ hour carving…

Oliver

I am pleased to report that I was able to fix my x-axis drift problem following @loftur’s solution. For me, the drift in the x-axis appeared to be dependent on motor speed. nearly every time I made a long rapid move in the x direction, steps were gained. I believe the root cause of the problem was excessive ground bounce on DRV8818 pins 7,21. Since the chip’s pull down resistors and the resistors R1-R6 formed a voltage divider, about ±1 Volt of the ground bounce was observed on pins USM0 and USM1. The fastest solution was to replace R1-R6 with something significantly smaller, yet continue to protect the voltage regulator from chip failure.

Thank you Loftur for sharing.

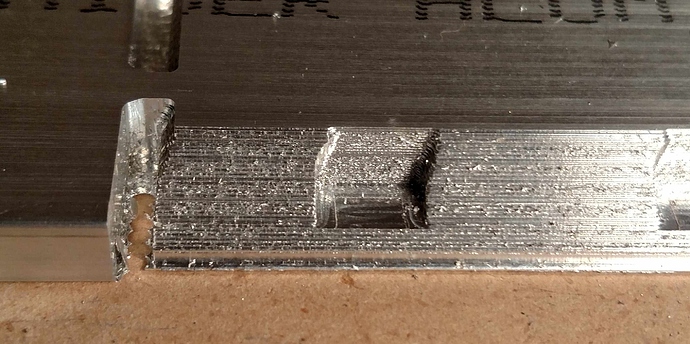

CUTS BEFORE:

CUTS AFTER:

Hi @UnionNine and @Jorge, would it be possible for you guys to post an nc file or something with a toolpath that would allow for users to check to see if they are having this issue? I’d really love to know for certain if it’s something I have to address, and I’m sure I’m not the only one.

Being an absolute beginner at this, my first assumption when something goes wrong is that I’ve made a mistake, so a machine problem might cost me HOURS of possible frustration before it would even occur to me to check that the Nomad might have an issue…

Just a thought.

The job I did which made it super easy to see the issue with is here:

Roughing pass only

Waterline pass only

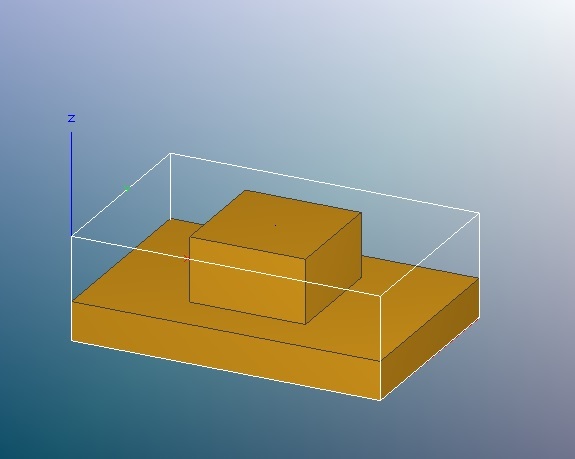

It’s a super simple model:

and it’s sized for the 3x2x1 blocks of renshape and wax we got with the machine.

You can see what the stepping errors resulted in in my earlier post here.

Also, if you have the same problem that Randy and I had, you can just run the first program in the air without actually milling away any material and you can even hear the glitches in the stepper motors as it runs. The glitch was manifesting itself apparently as the motors taking too many steps every once in a while, so you can hear the motor, while the mill should be going in a straight line at a consistent speed, occasionally go up in pitch for the tiniest fraction of a second.

Hi

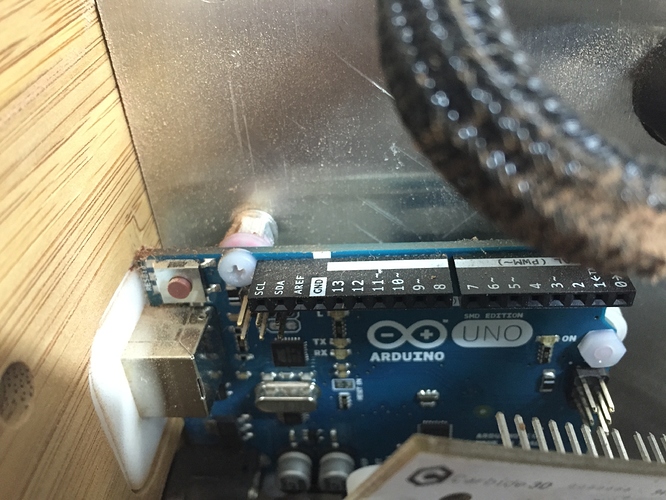

I am replacing my board today and removed the old one, but didn’t take a picture of on which Arduino pins the stepper board was connected to (I know…)

Can somebody let me know?

Thanks

Oliver

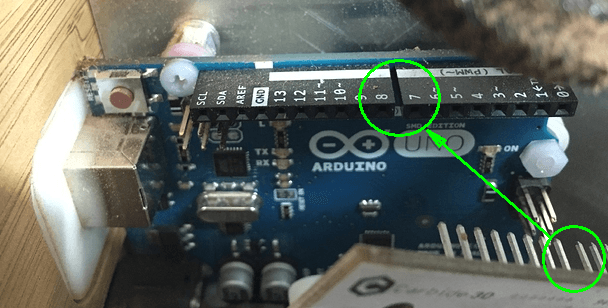

I got it actually, for reference: Pin SCL and SDA are NOT connected. That helps with the alignment

Oliver

[for those who come after] It’s actually pretty foolproof. The larger gap in the row of pins on the stepper board lines up with the gap between the two Arduino headers. You really can’t plug it in any other way because the distance between sockets 7 and 8 on the Arduino is smaller than two regular (.100") pin spacings.

Also what Oliver said.

A post was split to a new topic: Shapeoko Homing Issue