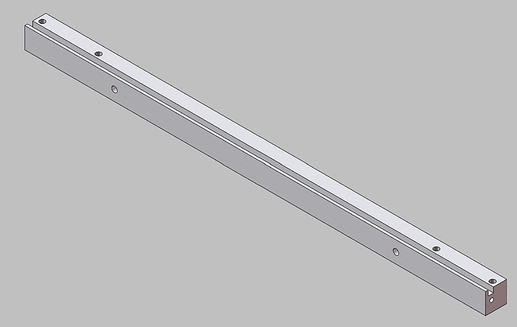

See below- this is 6061 aluminum bar, 3/4" square & about 18" long. It has a 3/16" wide x 3/16" deep slot & I just slotted four of these using my go-to Amana HSS1621 (HSS single flute, 3/16"). Used .031" DOC, 21000RPM & just ran it right down the center of the slot six times. The first four passes went well but the fifth and sixth struggled. It ended up leaving chips glued to the side walls, and I assume this is due to rubbing & chips welding to the wall as it gets deeper and can’t clear chips properly.

I slotted something similar a few weeks ago using all the same settings, but the slot was 1/4" wide & I cut ‘around’ the inside perimeter of the slot. It cut beautifully.

Aluminum cutters - maybe I’m not describing it quite right, but do you think what I’m seeing is because I’m cutting a 3/16" slot with a 3/16" bit? How would you do this? I can change the slot width… maybe make it .200" wide & use the same bit, or I could switch to a smaller bit (or something better for this) & keep the slot width the same.

If (when) I work this out I’ll have an opportunity to cut lots of these.

Thanks!