I’m using the latest CC, build 713, although I have had the same problem with earlier versions. I’m trying to pocket a 0.250 slot with a 0.250 endmill. I’ve tried to manipulate the software thinking the issue might be stepover or even finish allowance. I’ve taken stepover to 100% and finish allowance to 0.000. Is this doable? If so, what am I missing? Thank you.

What material are you cutting?

Does the lot have to be .250 wide? you may be able to cheat the software by editing the tool diameter to .2495. If it does need to be 0.250, then I would use a .1875 endmill. There are collets for the routers to hold a 3/16" bit.

either make the slot 0.2501, or the tool 0.2499. Output in inch gets rounded off to 3 dec.places, so the result will be the same as using a nominal tool. ![]()

Similarly, if you want to pocket 0 depth, enter 0.0001 as the depth. It will output 0.000

The current project is in MDF, so the softwood library.

Yes, I can play games with the width but my point is, I should be able to do this.

If I made the tool smaller by definition, the gcode would drive oversize to compensate for it.

Yes, I can also do it with a smaller tool but I don’t want to make a tool change only for this operation.

Can we somehow have an option to force the software to slot OR a slotting toolpath? Please.

Tod1d, this doesn’t work for me. Still says Empty Toolpath.

When cutting a pocket the narrowest area needs to be ~10% wider than the diameter of the tool.

If the dimension of the slot is important, the most expedient thing to do is to use a smaller tool and cut as a pocket.

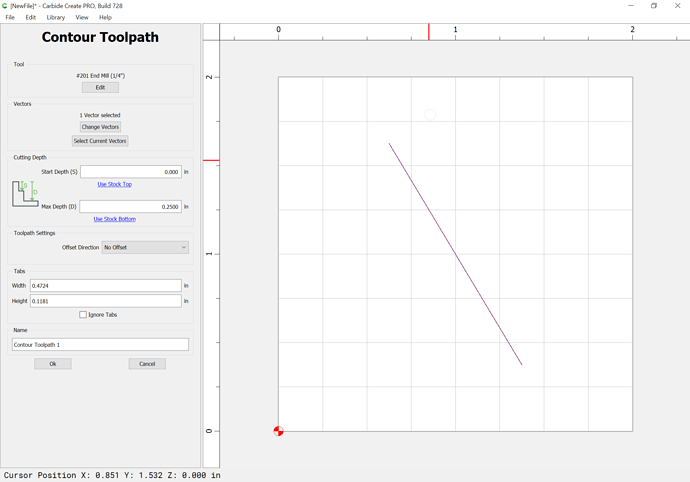

If you want a passage just the width the tool cuts you can use a no-offset Contour toolpath:

Drawn/placed so as to be at the center of the rectangle and less in length by the diameter of the tool.

Hmm, weird. It worked for me, I just tried it. I used a 0.250 tool on a 0.2501 slot & got a path.

So when I entered the circles for the end, I used a radius of 0.12505.

When one gets below 110% of the endmill diameter it’s hit or miss whether this will work or no.

The current released stable version of v7 is 726. You might try upgrading to the current stable version instead of the Beta versions below 726.

Toolpaths that are .25" wide and using a .25" bit usually do not work. So as advised above make a custom tool that is smaller than actual tool width or make the .25" slightly wider otherwise the toolpath will not make. Depending on material for a slot just as wide as the tool take the depth of cut (DOC) down to keep from getting tool chatter because a full engagement tool in hardwoods makes the bit deflect and chatter resulting in fuzzy cuts and less than perfect results. With a reduced doc it takes longer but in the end you get a better result.

Will,

Perfect! I knew there had to be a simple approach. D’uh, I get focused on ‘pockedting’ and forget about the contour path. This is moment I feel like a DA, lol. Thank you all.

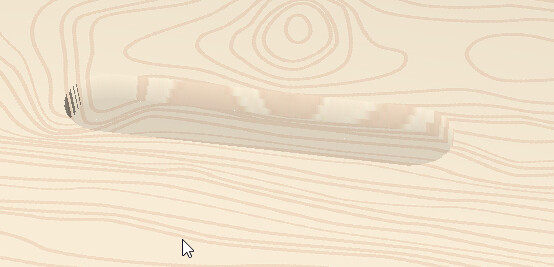

Please note that pocketing is preferable to slotting — it has lower tooling engagement and usually results in a better finish and better dimensional accuracy.

Will, I understand what you’re talking about, but isn’t the first pass of each level going to be a slot (100% engagement) path? (Unless your stepover is less than 5% of the tool dia.)

Assuming the concern is a squirly path that chatters because of full engagement, then only 1 side of the slot is getting ‘cleaned up’.

Yes, the first pass at a given depth has to be a slot (unless one is using adaptive/trochoidal toolpaths — one can strategize on the toolpath orientation/direction to ensure that the side which is cleaned up is the one which one wants to look nice — or just leave a roughing clearance and take a full-depth finishing pass.

This topic was automatically closed after 30 days. New replies are no longer allowed.