I was moving my shapeoko to install the new bitsetter when the little metal crown where the foot screws-in snapped. I do not own a welder .What are my options to fix it?

Do I need to replace the entire black bracket?

Those are PEM nuts.

Usually they pop out completely.

I suspect though, that you could just epoxy the broken part into place, a metal-impregnated epoxy such as J.B. Weld should hold it well enough (just run the bolt threads all the way in before it sets, then back it out without disturbing the part so that it’s not epoxied in place).

If that doesn’t work, contact us at support@carbide3d.com and we’ll do our best to work this out with you.

Thank you for your quick reply.

If it’s possible to pop a new PEM nut in the hole, what are the appropriate dimensions?

Yes, if you drilled out the old PEM nut you could probably epoxy a new one in place — contact us at support@carbide3d.com and we’ll do our best to help on that.

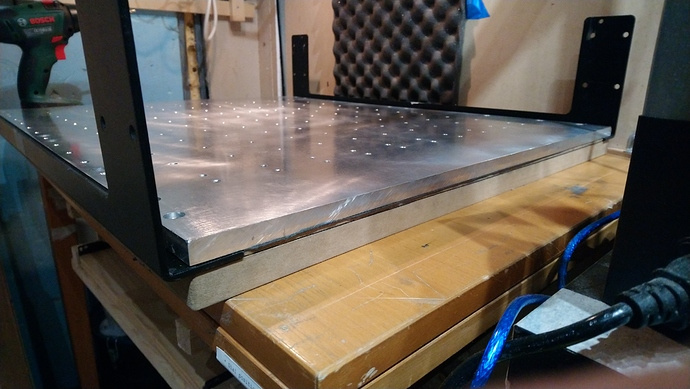

or, take this opportunity to get rid of all feet and lay your shapeoko directly on a flat piece of material (with just a few holes to accomodate the parts sticking out of the underside of the steel plates). I (and many others) did this, and I can now push onto the wasteboard like a madman when tape&glueing stock material, without having to care about flex.

(sure, the aluminium bed helps too, but the same principle makes even more sense with an MDF wasteboard)

I built my table top without flex (torsion top) and never installed those “feet”. My machine sits on the metal frame that holds it together, and I never move it. Now with an additional wasteboard installed, I don’t see any flex in my cuts. Since I’m just beginning, I’m not doing any tough cuts, but I am cutting a lot of large thin stuff and getting even cuts all over.

I third what these guys said. Take the feet off, knock the rest of the pem nuts out and bolt to a torsion box or 5/8” aluminum plate if you can justify the price.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.