I have had the shapeoko pro xxl for two months and not one project has come out. I have oiled everything made sure all belts are tight. Tightened loose screws i am at the point to trash the machine or sell it but cant justify selling this crap to someone else.

Can you describe in a bit more detail the issues you are having. I am sure the collective here can help you through anything…

Looking at the last 2 pictures I only see some fuzzies that can either be brushed away or hit with light sanding, that’s perfectly normal. The quality of wood and sharpness of bits dramatically affects the amount of fuzzies you get.

Hi Nick fuzzies i could handle its the circles not staying stright circles overlapping and line in flag on left moved up along with wording.

Machine seems to jump lines up or down whenever it chooses.

The machine is “dumb” in the sense that it only does what it is told to do. So this means 1 of 2 things… There is an error on the CAD side of things or an error on the machine side of things that needs to be identified and addressed.

I would try creating a single circle a few inches in diameter and cutting that. Doesn’t need to cut all the way through, just enough that you can measure it and make sure it is a perfect circle. Generally speaking if its a perfect circle then the machine is calibrated correctly. Next is to look at the CAD side of things.

Create something simple and test. If the results are not what you expect post a picture of it in CAD, a picture of the results and attach the code

We will all help you through this!

We have a ticket with you were we asked you to check some mechanical aspects of the machine on 24 March — are you having difficulty checking these things?

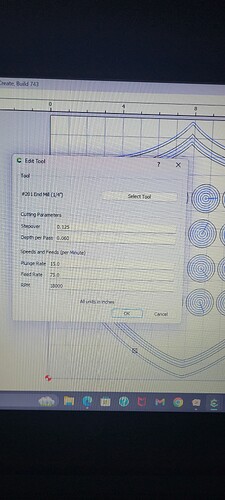

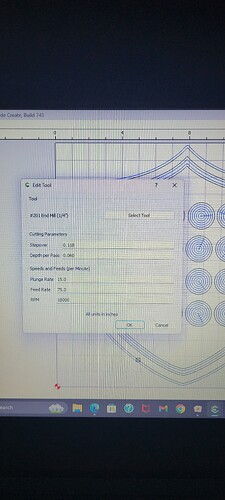

based on those pictures it looks like you are missing/skipping/losing steps at some point during your gcode being run. What feeds and speeds were you running on those projects? Might be that the machine is being run to aggressively, and skipping/losing steps at some point.

I have done all the steps asked to do

Then please let us know about this at the e-mails where we asked after them.

How Much and location?

Julia

I don’t know what you were asked to check but please follow up with support they will get you up and running.

In my opinion you may have several problems

Lose belts and maybe wiring issues. All of your circles look to be flat on the same sides and this could be belt tension. As far as wiring issues I would check all the connections and make sure the pins are all pushed in properly.

Hope this helps some and Support will help you a lot.

Anthony

Could we also see your work holding techniques? It’s just another variable to double check.

Don’t give up!!!

When I first started only 10% of my projects turned out. My son loves burning the “oops” projects in his Chimnea.

Now 3 years later, I only mess up about 1 project out of 10.

Usually, the 1 in ten I mess up is because I am trying something new.

There is a learning process to this.

A great quote that I like to tell myself: “Nowhere is it written that you must be good at your hobbies”.

LOL.

The photos you posted look like work-holding errors.

I put a brad nail into the stock on all four corners for Flags. This locks the work in place and helps it stay flat.

Can you post the files?

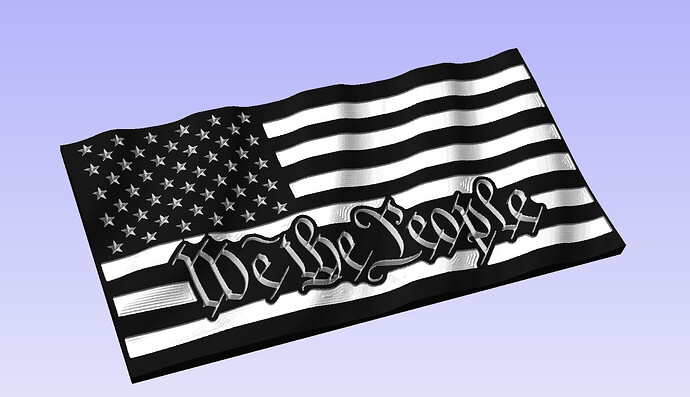

Looks like you are doing a WTP flag and a Poker Harley Davidson Shield. Those are both great starter projects. The WTP flag is a bit advanced, but it looks like you followed Full Steam Designs video.

I use tape and super glue plus clamps to hold down I will try the brad nailer and see if that helps thank you

Yes I do follow Full Steam Designs but I actually brought the C2D file for the flag.

WTP Flag 21 x 11.c2d (232 KB)

This was one of my Very First Projects. I ended up doing a Blue Line on it and giving it to the local Sherriff’s Department.

3 years later I am way better at this.

I use double stick woodworking tape. It usually is great but I had a project I was working on for over a week due to waiting for epoxy to dry and ended up having it bow up slightly in the middle. A couple of brads resolved that issue easily. I did have my piece on a piece of MDF on top of my normal spoil board.

Thank you so much Fleming for doing a video chat and help find the issue with my machine and expedite the parts to me. Hopefully i will be posting completed projects soon and loving my machine. Thanks again Julia

I found that when I first started using the machine, if you don’t select the appropriate model of machine with the carbide motion software, it would do random things wrong. This is done only once, and sends the correct machine configuration codes into the machine controller. I bought the original xxl about 3 years ago and have had great success making hundreds of projects. I sell Carbide Create CNC project files on Etsy under a shop named “HandyHusband”.