Let me start by saying I’m not an idiot. I’ve built several benchtop CNC machines and large format 3d Printers. I understand this stuff, really.

History:

I purchased my SO3 in January this year. It arrive Jan 13th to be exact and after the weekend, I was making chips. Cool

The problem:

On March 3rd, I noticed the X-Carriage had begun missing steps and the part I was cutting was now offset. Suspecting wood chips or ? had gotten under the belt I dug in and found a portion of the belt was smashed and actually look as though it had melted.

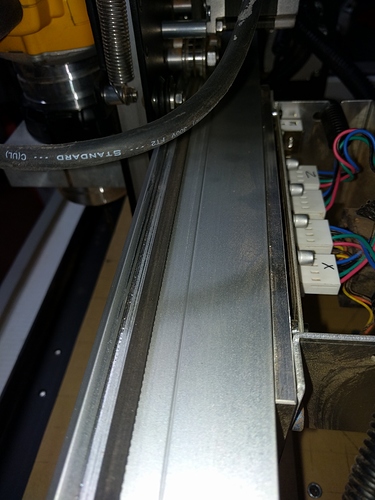

Now if you look closely at the image you can also see scratches on the x-rail.

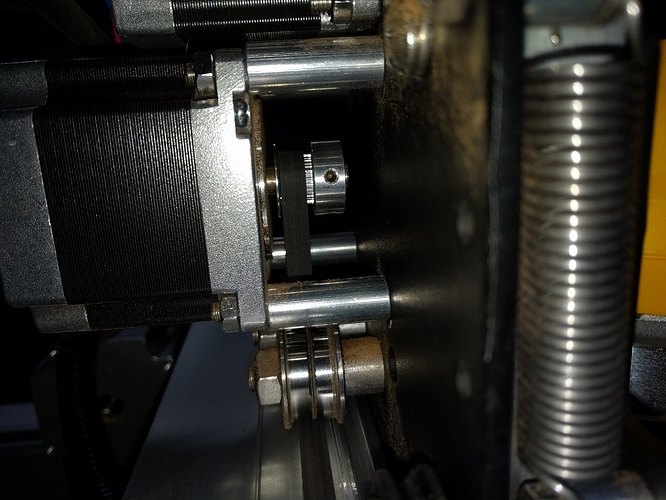

Here is another angle.

So now let’s find the source of the problem…

That was easy, it’s the idler bearing for the X-Belt. It is actually supporting the top of the X-Carriage.

Emailed support, we talked a little, we came up with some ideas and since I travel a lot, we didn’t rush to get a solution out right away. Last I heard from Ed was on March 16th, he was going to test somethings and get back to me.

Fast Forward to March 31st. Had not heard from Ed or anyone on the team, so in the meantime I replaced all the belts on the machine, cleaned up the x-rail as best I could and added some shims in the mounting holes for the x-carriage v-wheel bolts. Everything was working well enough to knock out a few more “SIMPLE” cuts. Until the Z-Carriage started to stick and miss steps.

I disassembled the machine again and investigated.

In case you can see it very well, one of the z-rails had been flattened (the dark line is actually the area ground down by something). This is the Left z-rail to be exact. What could be causing that???

Again, a little hard to see, but if you look closely at the stationary z-belt pinion gear, there is a dull spot between the two set screws, it is rubbing on that z-rail.

Reached out to Ed again that day. Sent him pictures, description of the problem, etc… and unfortunately still have not heard a peep from ANYONE since March 13th.

I’m usually a VERY patient individual, but in a follow up email, I even asked for them to quote me the costs for new parts and shipping, don’t care at this point I just want to see this thing cut a few more pieces of wood!!! NOTHING… Not a dang thing.

I was ok until last night when working in the shop to try and make this hunk of metal move again with what I have and my wife walked in and said “You bought this so you could enjoy your hobby, this thing has done nothing for you, but make you mad and waste your time”.

So this is my desperate attempt to get SOMEONE to pay attention to me and I really hope it works. I’m just about sick and tired of this dang thing breaking down every two cuts due to POOR Design and BAD quality control.