Spent last couple days finishing up the enclosure and adding some small bits to the machine, so while the progress might not seem significant, all that ‘little’ stuff had to be done and was rather time consuming.

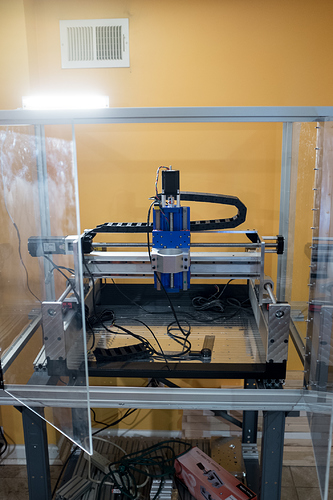

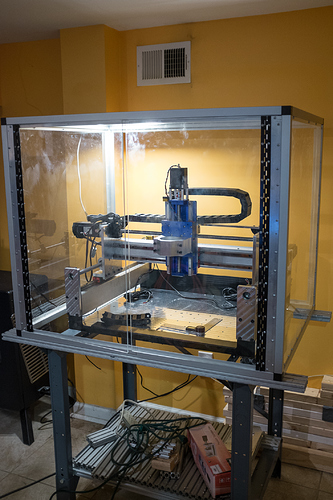

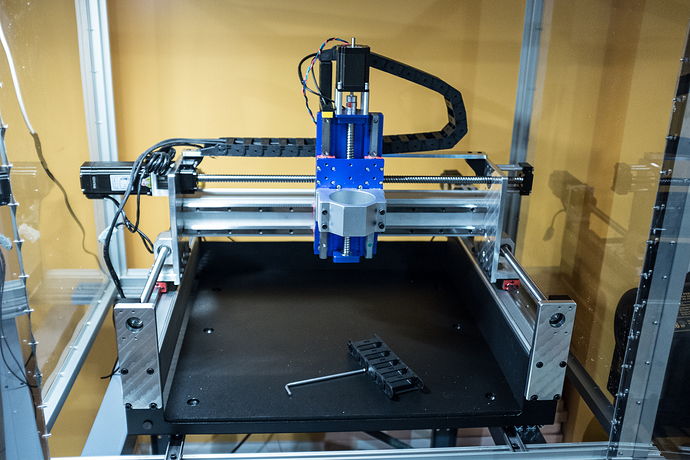

First of all, added plastic panels to the enclosure at the front and sides. Front doors need some adjustment and handles  I’m going to get neodymium magnets and 3d print some brackets to use as a magnetic door latch. Top part of the enclosure will be made out of white corrugated plastic as well as the back. The enclosure was designed in such way that the motors will be sticking out in the back. Still haven’t figured out what to do about the bottom part. Like I mentioned before it would be ideal to have some kind of hopper that would move chips into a bucket, but I haven’t figured out how to make it yet to be cheap, simple and least time consuming.

I’m going to get neodymium magnets and 3d print some brackets to use as a magnetic door latch. Top part of the enclosure will be made out of white corrugated plastic as well as the back. The enclosure was designed in such way that the motors will be sticking out in the back. Still haven’t figured out what to do about the bottom part. Like I mentioned before it would be ideal to have some kind of hopper that would move chips into a bucket, but I haven’t figured out how to make it yet to be cheap, simple and least time consuming.

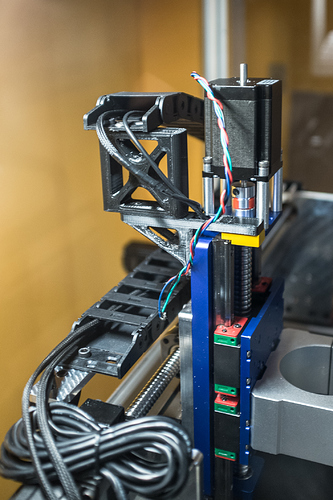

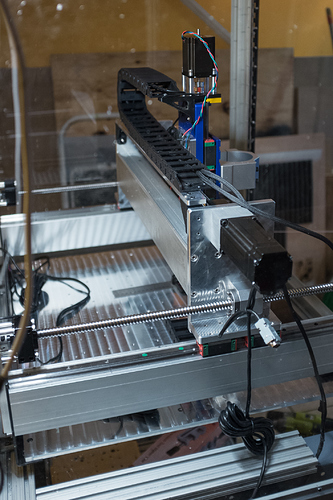

Finally added the top drag chain and it got mounted to the 3d printed brackets. I know the two pieces don’t align and I should print another one to make it look a tad better but it was super late at night when I was designing it, plus for now it does the job perfectly.

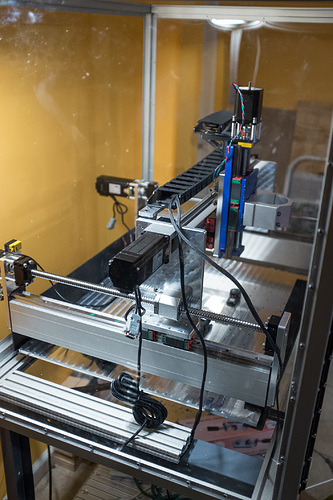

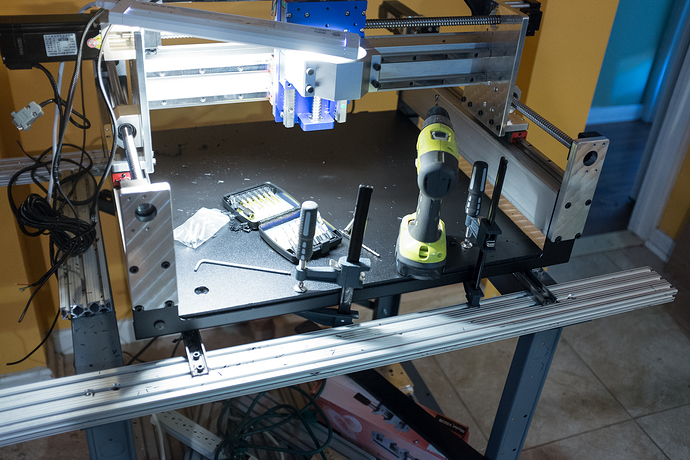

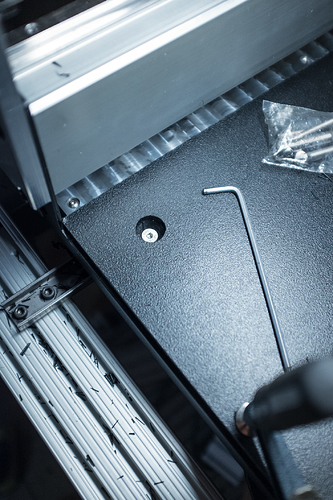

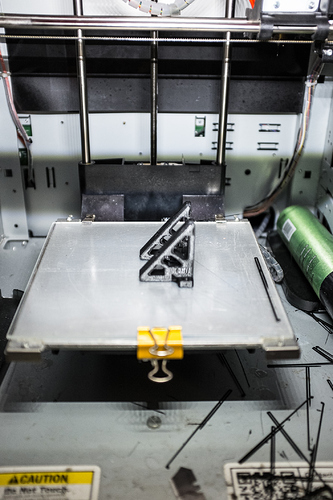

I’ve been waiting for about a week for the 3/4" hdpe board to arrive but it’s finally here. 24x24 board had to be shorten about 1/2" to fit on the so3’s bed but it was easily done with a jigsaw. Clamped it to the table, drilled small pilot holes from the bottom through the aluminum table’s threaded holes and then re-drilled them from the top. Used m6 countersunk bolts to mount the board to the table and made sure that the holes are plenty deep. Board will have to be surfaced and tapped before the actual aluminum table will be installed. Still need to add bolts in the middle part of the table but that won’t happen before I know what is the exact size of my cutting area. Don’t want to crash into a steel bolt while drilling the holes. Enough talking here are the pics.

Maybe silly thing to mention but I’ve also designed some small brackets for the led under cabinet lights that I had laying around. Will have to add another one on the side of the enclosure.

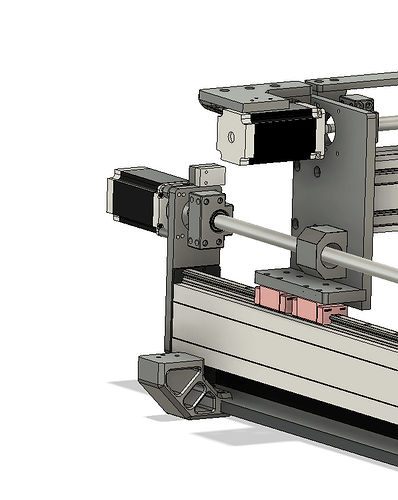

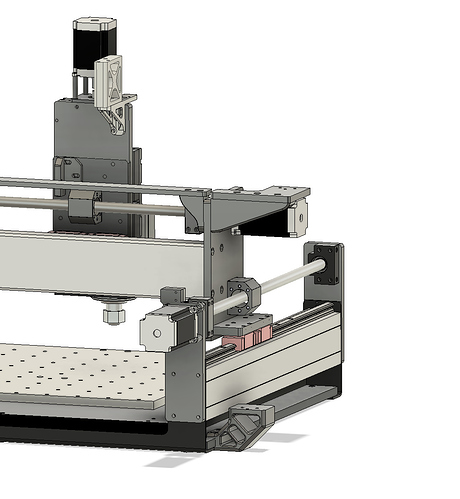

Started working on the second drag chain but all I managed to do was mach up the placement of the top part that will be installed near the x axis motor.

I know it doesn’t look that well yet, because I still need to cut a aluminum ‘shelf’ that the chain will be bolted to. It should extend over the motor. Didn’t want to go with fully 3d printed one because don’t know how hot those motors will be getting while energized. They’re closed loop so in the theory should be significantly cooler than regular steppers but better safe than sorry. Don’t wan’t to have a melted PLA stuck to the motor. When done it should look like this ->

The bottom chain bracket will be bolted to the original aluminum table.

Hopefully my power supply will arrive this or the following week, so before that happens need to have a electronics enclosure designed and made. I’m thinking of mounting everything to the 1/4 aluminum plate and have corners 3d printed. I’ll show exactly what I mean some time this week. I could go with a pc case like I did on my other machine but this solution should be easier and look better.

Thanks for reading