Hello,

First I want to say thank you to Carbide 3d over the years with offering an affordable CNC machine that has allowed me to start a business, quit my full time job and now begin scaling up to a production shop. My business has grown at over 100% per year for the last 3 years since it’s inception which is good fun.

I have over time been upgrading my SO3 to meet my increasing demands. There have been months where I have ran it for nearly 40 hours per week and it has proven to be a workhorse. The vast majority of my machining is carbon fiber as well as cutting out 1/8 inch aluminum plates.

I have contemplated purchasing a CNC Router Parts Benchtop Pro for awhile now as moving forward I am going to start machining aluminum molds for pre-preg carbon fiber among other things. This will require more rigidity and precision. I decided since I was already pretty heavily invested into the SO3 and I’m familiar with it that I’d just try to upgrade what I have.

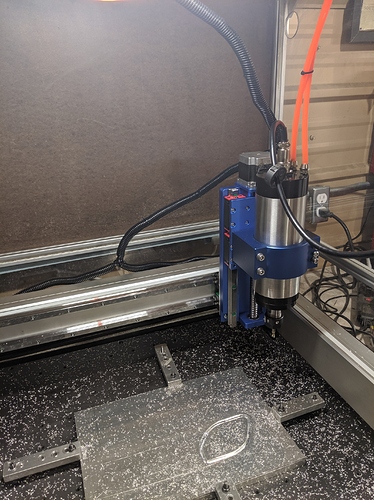

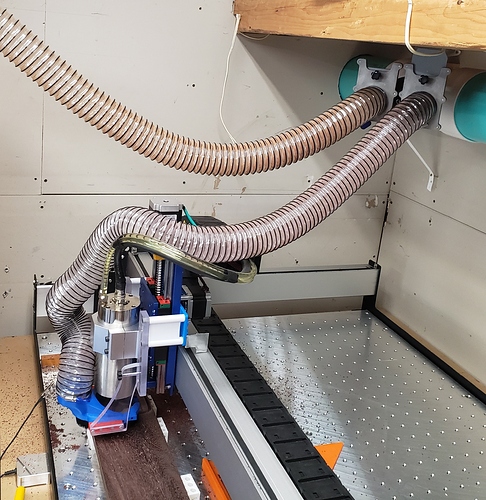

So what I’ve done in this series of upgrades is change the X travel to use a linear rail, upgrade to HDZ and a 2.2kw water cooled spindle.

I wanted to get everything installed and confirm that it runs properly before finding a permanent place for everything like the VFD, water pump etc.

Before booting up the spindle, the machine can rapid and jog in all directions flawlessly.

The issue: Once the spindle is turned on GRBL outputs “Error (x) GRBL ERROR: Serial Port: Unkown Error” and the machine becomes disconnected. The issue is directly related to the spindle turning on. The VFD can be powered on and the machine will move perfectly fine, but repeatably once the spindle is turned on the machine disconnects. I put an “x” on the Error number as I have gotten a (3, 31, 34, 35, 39 &41) and those are just the ones I’ve written down.

I’ve had issues like this with my SO3 and SO3 XL (seems to be a pattern) but usually have been able to solve it by making sure there are are no other cables touching the power cable or USB cable since as far as I know the EMI messes with the controller or something. I’ve had this problem before on this exact machine and solved it with some combination of moving around power cords and USB cables until it was happy again.

It seems no combination of moving the cables will resolve this. The power cable and USB cable is not touching anything else. I even moved the spindle cable going to the VFD out to the front of the machine to see to make sure it is not touching anything.

I then tried to have the CNC off while the spindle was on and running. Then power up the machine, home it and run a proven program. It worked for about 4 minutes until the issue came up again. I know this is a proven program as I’ve ran it nearly 100 times before. I took the endmill out and ran the program with the spindle off and it ran perfectly fine.

I have grounded the machine, The threaded table is bolted to the countertop with M6 screws and the screws are connected to a earth wire going to an outlet.

The only thing I can think of to try next is to change the cord going from the spindle to the VFD. It came with a 12/3 cord, so no grounding wire. I could get a 12/4 cord and use the grounding wire and see if that makes any difference?

Any help/advice would be appreciated as I’m dangerously close to just buying the CNC Router Parts Benchtop Pro.