A while back I noticed considerable deflection in my SO3 XXL bed while cutting aluminum. During the plunge the bed would push down and then slowly raise back as the cut progressed. Did some measurement with my dial gauge and it was about 1.5mm of downward deflection with light pressure.

The rails on the SO3 XXL are actually convex, mine had a ~6mm rise at the center. Hard to capture in a pic:

Under load, when fully assembled with the weight of the bed, etc., this rise levels out and prevents sag. All good, but I was not happy with the flex and deflection during some cuts. I’m also working on a vinyl cutting project and needed a more consistent surface for the precision a vinyl plotter knife needs.

Of course I missed capturing all the steps ![]() but easy enough to understand here.

but easy enough to understand here.

I used the same threaded inserts as I use for my spoil board and dropped 6 into my table, two for each rail. Really, this was too many and one in the center of each rail would have been sufficient. I ran a bolt through the rail and then shimmed with pieces of 1/4" and 1/8" ply to hold it firm. I put a level down the length of each rail as I was tightening it down to get it as close to flat as possible.

I wasn’t too worried about extreme precision here, since resurfacing the spoil board will fix any fractional mm I was off, but got it as close as possible and tight against the shims. Remounted my base boards and then my spoil board followed by a resurface.

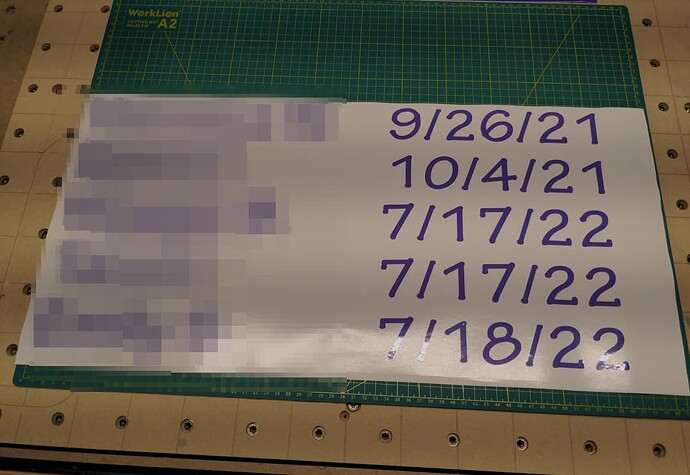

Now my bed is very rigid and flat, had great results on a my first vinyl cut:

Looking forward to testing out an aluminum cut soon since this is where I really noticed the downward deflection having an impact.