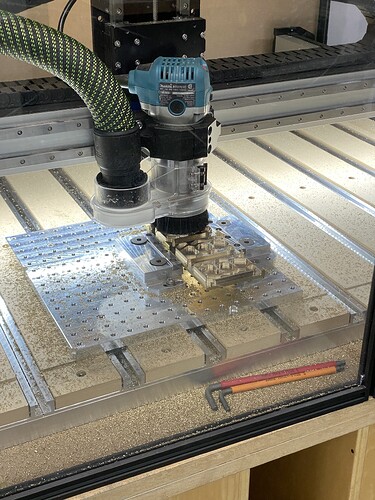

I’ve been working on these small end plates for a couple of months. I typically design in Fusion, then post process there, then across to carbide for running the gcode.

My first 6 months of working with metal was useless, but these days it’s pretty successful.

Just wanted to pass on what I use in case it’s useful for others.

Fusion for modelling, then export into Bambu labs for 3d print prototyping. (This is 80% of my project time). Prototyping in a filament printer is a game changer.

Fusion for manufacture export gcode to Carbide. Carbide for machining because for me it’s 100% reliable.

Shapeoko pro. SandersMachineWorks plate and jaws. Datron 4in1 8mm single flute. Just amazing on alu and brass. Datron 3mm single flute for detail. No lube or air. I have Festool shop vac with anti static hose attached , others may feel there is safety issue but I never leave shop when my machine running.

Machining. Normally 3d adaptive, but be aware for many jobs like these pockets it’s very slow to compute. So the main form is 3d adaptive but pockets are just 2d adaptive and select pockets which is super fast to compute. On Fusion careful with the fillets checkbox on the passes tab, it adds a huge amount of time to cuts.

If I have double sided jobs (most of my jobs), then I use Fusion to emboss the top side of the part into a flat cuboid. I then 3d print the cuboid as a precision holder for my flipped part so I can machine the bottom.

Speeds and feeds for alum and brass

3mm 20,000rpm at 500mm/min = 0.025mm fpt. 60% tool diameter as step over, 0.6mm step down.

8mm same except 25,000rpm at 600mm/min.

I dont need any finishing paths with the Datron.

Raid your local scrap merchant for alu off-cuts but I import the brass because it’s stunningly expensive here and is the exact same brass imported the exact same way but 300% the cost.