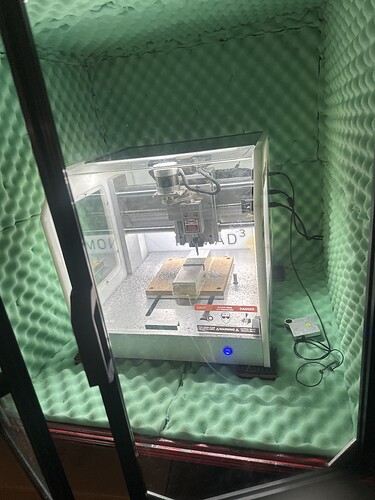

I recently created an enclosure with 2 mass loaded vinyl layers one on the inside and one on the outside with an egg crate sound foam on the inside. I still have quite of noise being produced while cutting aluminum. How does the idea of putting foam in the interior of the machine sound? Do you guys think it’s a good idea? I need feedbacks and don’t want to just waste money and buy things

What about insulating the doors?

Curious if you measured the decibels before/after the makeover?

Is it possible to fill a void in-between exterior and interior walls with rock wool?

Interesting you said that, since I stapled the foam egg crate on the inside with a staple gun on top of the mlv layer, should I remove the egg crate slowly from the inside then apply the wool then restaple it back, Is this effective in reducing sound?

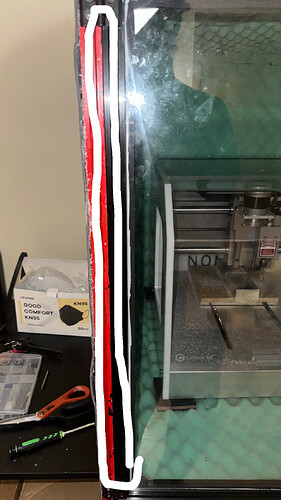

I haven’t measured the decibel but I can definitely tell there is some sound reduction in the making. Before it will be as loud as it could be since I can hear it pass through walls with high frequency waves but now Theres a slight difference. I know the high rpm and feed rate can play a part in creating the high frequency since I tested it out. I didn’t insulate the doors which most likely I need to do since I can hear sound escaping at the doors. Should I use rubber sound insulating tape or polystyrene foam for the edges?

I was referring to insulating the entire door. Glass or acrylic is going to pass way more sound than the insulated walls. Download a decibel app and move it around. You should get much more noise near the doors.

Dual pane glass/acrylic might make a good difference.

Insulating the inside of the machine enclosure I expect would get pretty messy. If anything consider the outside.

I’m guessing you’re shooting for silent from outside that room?

I made my HDM enclosure from 1/2" PVC for the sides, and Acrylic for the top & 2 doors on the front & back. I’m getting near 20dB reduction with the doors closed. But Mine is in the garage so I don’t need, or want it completely silent. If I happen to walk away for a minute I want to hear it.

At this point, you may be better off insulating the room ![]()

Rock wool is supposed to be very effective (convincing demonstration on This Old House from a while back) — probably the structure you suggest would work well, and ideally, it would be set up so that the egg crat could be easily cleaned/replaced, so that the rock wool wouldn’t become contaminated.

I can verify this as I’ve tried sound dampening acoustic foam & Rockwool - Rockwool Comfortboard80 is definitely what you should try using. It’s easy to cut/shape with a knife, can be mounted with screws/washers & can be primed over to keep the surface fibers being brushed off. For 1-1/2" thickness, if you were to encase the Nomad with it inside your enclosure, it would help a lot.

The thing about cutting noise is that the higher frequencies can penetrate through the smallest cracks in an enclosure - especially around the doors. Rockwool Comfortboard I have found helps the most to dampen this noise. Even just using it as an acoustic seal around the edges of your enclosure doors would probably do more than all the acoustic foam you’ve already got in there.

My experience has basically shown me that acoustic foam is pretty useless when it comes to the noise levels of cutting tools in a reasonable thickness.

One of the better things you can do for noise AND the life of the machine is to buy a small grinder and chop off a couple mm from the back of the endmill if you don’t need to cut through thick materials. The less stick-out, the less vibration possible, and the less stress on the spindle bearings. The 278-Z and most single flutes stick pretty far out of the ER-11 collet.

I got done insulating the panel edges on one of the door with weather strip and adhesive tape you can zoom into where the edge of the panel is to see it on the second picture, only problem is where the hinge is located near the structure of the door. I can detect a gap. As you mentioned “applying wool around the edges of the door” especially on the inside where the hinges are will it help out closing the gap and reducing noise escaping? I will then remove the foam on the inside then apply wool then reapply foam. But I’m just curious if wool is all it takes to block sound in the gap proximity of where the hinge are located. Here is a picture for reference. The circle is where the location is.

foam like sound reduction material does exactly one thing: it reduces the reflection INSIDE the room it is installed thus reducing the energy that hits the receiver (ear) inside.

It does not (almost not, just very little) block the sound energy to be transferred to the wall of that room. If the wall has little mass, it swings as the sound waves that hit from inside, transferring it -forwarding the swingings- bravely to the outside.

It needs a high mass wall to efficiently reduce transfer of sound waves to the outside of a noise producing room. Also vacuum does not transfer mechanical waves very well: hence there is no sound in outer space, except in StarWars, what is another universe of course ![]() : means either thick window glass or those vacuum layered glasses, possibly with 3 glass layers.

: means either thick window glass or those vacuum layered glasses, possibly with 3 glass layers.

The more space the layers have the better the noise insulation is.

Thick layer of stone wool is a good compromise.

Rockwool Comfortboard is a compacted mineral fiber board 1-1/2" thick. It has substance & density to it that does a lot more to dampen noise than anything else I’ve tried.

If I were to apply wool on the inside my main concern would be the weight of the enclosure, can I just remove the mlv on the outside without worrying about sound coming out since I have wool to use? The mlv is 1/8 thick 1.25 ib square ft

You’re quite right, the foam won’t be doing much to absorb noise or prevent it escaping the enclosure. This sort of light foam is largely ornamental at the frequencies from a CNC.

This porous structure with low mass and little thickness will have a small impact dispersing the highest frequencies within the enclosure, but the majority of the audible spectrum will pass straight through it, reflect off the solid backing behind it and carry on as if the foam wasn’t there.

Some diffusion or absorbtion on the inside of the enclosure would likely reduce the sound passing through the doors by reducing the noise level in the enclosure, rubber carpet underlay or similar high density, and less flammable, materials are a common choice for that.

Otherwise, as suggested above, some nice thick rockwool, something like the heavy acoustic grade knauf earthwool if OP can find it, in a sandwich to absorb sound energy on it’s way out of the box is likely the best bet, once the sound leakage via the doors is managed.

Regarding the mass loaded vinyl, is this an automotive product?

There’s a few situations where these high mass coatings are applied, in old school speaker cabinets bitumen felt was popular.

In general these high mass coatings increase the mass of a panel and therefore reduce the resonant frequencies of the panel (as they don’t change the spring from the panel stiffness). This can be helpful, especially with thin metal panels in vehicles, in moving the resonances down out of the audible range.

In some cases these coatings are in the form of a thin rigid layer with a visco-elastic coating which bonds to the panel you wish to damp. The good ones are constrained layer damping systems which use the two rigid layers to force the visco-elastic rubbery layer in the middle to turn vibration into heat. These tend not to work on wooden panels as the tuning of the system is quite sensitive to the materials.

To absorb sound inside the cabinet a heavy foam is probably the best start, something which is flexible enough to be vibrated by the sound at the frequencies we wish to damp, but thick and heavy enough to absorb a reasonable amount.

If the MLV is having a significant impact, it may be that bracing the panels would help even more.

HTH

My main concern then would be the weight of the enclosure itself since I want to make sure it’s easily movable when it’s time to move. Since wool is the best option. should I consider removing the mass loaded vinyl layers on the exterior walls? The exterior mlv layer add up to 26 pounds approximately. I already have mlv on the inside to help with low frequency. Here’s my schematic of the interior enclosure wall -Birch Plywood (1/8 thick) → mass loaded vinyl layers (1/8 thick) then last the foam you see in the picture (1 inch). Would this be enough with the wool under the foam to block high and low frequency noise to then not need the exterior mlv?

Hah,

I get the time to move thing ![]() When I moved my SO3XXL on it’s torsion box I had to roll the whole thing on a pallet truck onto the tail lift of the moving truck. The moving company were not happy

When I moved my SO3XXL on it’s torsion box I had to roll the whole thing on a pallet truck onto the tail lift of the moving truck. The moving company were not happy ![]()

I’d suggest that you make the enclosure bolt-together so you can strip it off for machine maintenance or moving, panels one person can lift are quite a bit less hassle.

If it were my machine I was trying to silence I’d probably go about it in approximately this order

- EDIT - If you’re using extraction, get a quiet vacuum extractor (DeWalt stealthsonic if you’re in the US)

- EDIT - Nomad already has a pretty quiet spindle I believe

- Figure out a way to make the enclosure door close onto a foam / rubber type seal, there’s lots of weatherstripping products out there for draft proofing doors that should work, then the noise isn’t leaking around the doors. Remember you’ll need some way for air to get into the enclosure to make up for the extraction though, a length of 4" pipe with a couple of 90 degree bends for an intake can block quite a bit of noise

- Consider using two layers of acrylic or polycarbonate (pref polycarbonate for it’s excellent shrapnel stopping) on the doors to make a poor-man’s double glazing

- For the side walls, the 1/8" birch may well be vibrating with the sound, this will be what the MLV is reducing. I’d consider bracing it every 12" or so to reduce the movement, rather than just trying to move the frequency with the MLV. A sandwich of 1" or 2" Rockwool comfortboard 80 as suggested above, between two skins of 1/8" ply for each panel, with some thick rubber / foam carpet underlay on the inside face. Don’t cross-brace between the two 1/8" birch ply skins, that ‘short circuits’ what the rockwool is doing.

Hope some of that is helpful.

What are the feet you’ve got the machine standing on? Transmission is another noise path, if those are a suitably compliant material they may well be reducing noise transmission direct to the cabinet.

Thanks for the feedback! ![]() The feet of the enclosure is covered in mlv I don’t have any feet since my enclosure is too long for my table. I will have someone make a custom table for me that includes the capability of adjusting in length since the length of the enclosure is wider than the door frame that will make it difficult for me to move around since that consist of removing door hinges. I will hire a Handyman to handle reconstructing the enclosure in half and reinforce with wood strips on the center cut of the panel on both the inside and outside the professional way so I can easily take apart with screws and bolts, since I’m new to wood work and I value my project deeply I want to avoid any mistakes made since I will be creating a watch business soon. I will post my updates here in the community. I deeply appreciate you and everyone in here helping out! Without you guys I would be stuck and not knowing what to do. Much blessings!

The feet of the enclosure is covered in mlv I don’t have any feet since my enclosure is too long for my table. I will have someone make a custom table for me that includes the capability of adjusting in length since the length of the enclosure is wider than the door frame that will make it difficult for me to move around since that consist of removing door hinges. I will hire a Handyman to handle reconstructing the enclosure in half and reinforce with wood strips on the center cut of the panel on both the inside and outside the professional way so I can easily take apart with screws and bolts, since I’m new to wood work and I value my project deeply I want to avoid any mistakes made since I will be creating a watch business soon. I will post my updates here in the community. I deeply appreciate you and everyone in here helping out! Without you guys I would be stuck and not knowing what to do. Much blessings! ![]()

Oooh, watchmaking, impressive, love to see some pics and description when you’re up and running.

Just seeing this. So I built a 2020 alu extrusion and plexiglass case for my Pro. Mainly because I use it for brass and alu machining. I have the makita router.

Couple of things I learned after using it for a year or two.

- It doesn’t all need to be plexiglass… I replaced the back and top(back half ) with 3/4” mdf.

- All sides of mine have doors. So one in front half of top, two on each side and two on front. All these bring gaps, so I put a wool felt bead buried half inside the door edges. Makes a big difference

- If you seal it enough then the vac(for me a big hepa Festool) will have to fight the seal, which isn’t good. So dont perfect seal as then you need to increase vac sound, which is outside the case.

- Noico bitumen-like sound proof adhesive sheet is easy to apply (used for sound proofing car door panels). I used mine under the hybrid table to reduce sound reflection from the mdf plate it sits on.