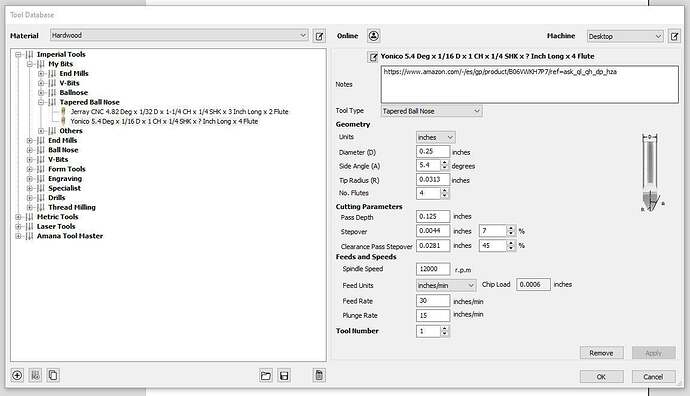

Hi. I have some 1/32 tapered ball nose bits, 1/16 tapered ball nose bits and I would like to start using them on oak and pine for a finish pass. Any recommendations from an experienced user? (I can’t find this info anywhere, seems like if was a super secret) I have a Shapeoko 4 XXL. Thank you very much

It’s a hard question to me because the chipload of the tip is hard to calculate. The very tip is literally rubbing no matter what you do, sort of. Since you’re not removing a lot of material, and finishing takes forever, I want to max out my feed. My SO3 gets kind of sloppy past around 3200mm/s. Then I usually try to walk the speed down to like 12k but keeping an eye on the visual effect and the sound. Sorry I can’t be more scientific, this aint no machine shop I just cut wood and plastic.

the trick is that for 3d carving (where you use these) you tend to do a super small stepover.

I’ve run these at 50 to 60 ipm with no issues on very hard woods – with the small stepover.

I’m sure some folks here would run even faster, but then it is about how rigid is the machine

and how solid your workholding

now this assumes that “the first zig” of the zig-zag has free space to move… which is great in theory

but a disaster if not true, so what I tend to do is turn the speed down in Carbide Motion to 10% to 20% before I start, let it start the first zig, and either reset to 100% when it starts the zag in case it cuts material on the zig, or instantly if it turns out there’s enough clearance.

Thank you very much! could you also recommend the pass depth for the 1/16 and 1/32 tapered ball nose and the RPM?

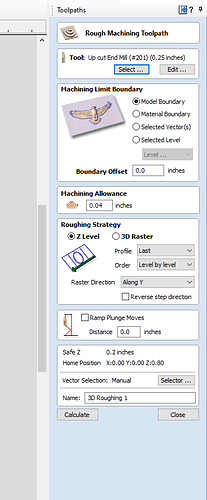

hmm for 3d finishing there is no pass depth !

I’ve not used my tapered ballnose bits for anything other than 3d finishing

Oh, So I guess is always gonna cut the “Machining Allowance” in one pass right? (Always the material left to cut after the roughing toolpath)

I use 1300rpm with my ball noses I think that’s setting 3 on the makita

Anything under 10% step over

Now feed all depends on if I have roughed it out first

Sometimes I don’t do a roughing pass depending on how deep the start of the model is

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.