The workbook supports that, we just need to determine what those force limits are! Need numbers and maybe a translator (0.5 cubes?)

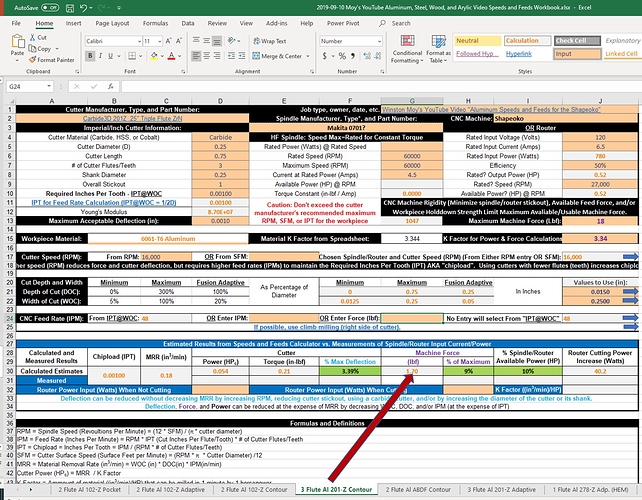

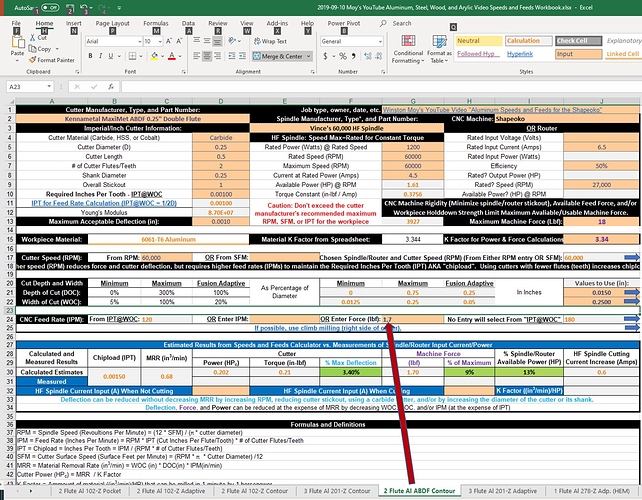

2019-09-10 Update: Since Winston already provided numbers in the videos posted here, I added sheets to the workbook for his additional Shapeoko aluminum and wood videos as well as his Nomad cast acrylic video.

2019-09-10 Moy’s YouTube Aluminum, Steel, Wood, and Arylic Video Speeds and Feeds Workbook.zip (373.9 KB)

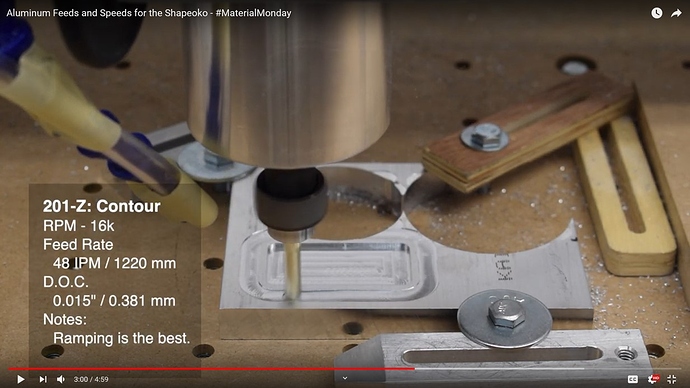

His most aggressive cuts were in the “Aluminum Machining Guide For the Shapeoko 3”

As shown below that likely required less than 1.7 lbf of cutting force and 40 Watts of cutting power and resulted in a MRR of 0.18 cu-in/minute. (That’s less than 1/10th the feed force and power capabilities of stock Shapeokos.)

As shown below, using that 1.7 lbf to set the feed rate for Vince’s 60,000 RPM spindle resulted in a MRR of 0.68 cu-in/minute.

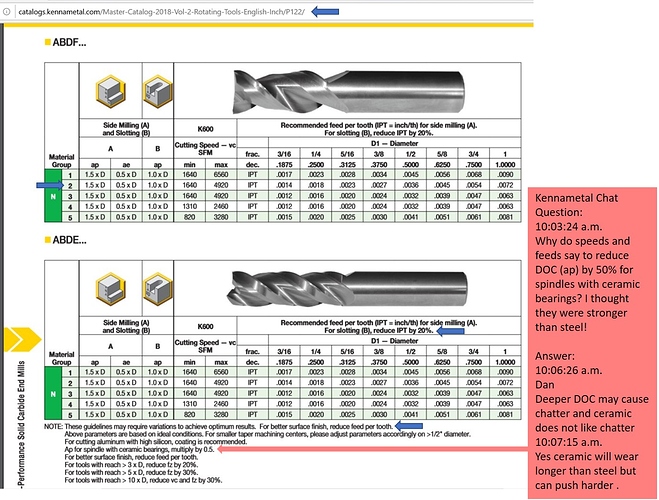

Since apparently no speed ratings are provided for the Carbide 3D endmills, they probably shouldn’t be used at 60,000 RPM (or even above Winston’s 18,000 RPM maximums?) So these endmills were used for those calculations instead.

Interesting that Winston’s reply to one of the comments on the “Speeds and Feeds for Wood on the Shapeoko” video supports my assertion that, at least with wood, “make dust not chips”.

" Winston Moy 2 months ago

Chipload isn’t really a big deal, so I wouldn’t worry too much about it. The reason it matters in other materials is heat. And here if you rub more than cut, you’ll just see a little burnishing/blackening of the cut edges. That you can recover from because wood is forgiving, in aluminum you’d break a tool. If it works, just go with it. Woodworkers have been pushing router bits through wood by hand for decades, and i guarantee you they haven’t measured their feedrates!" ![]()