Evening all-

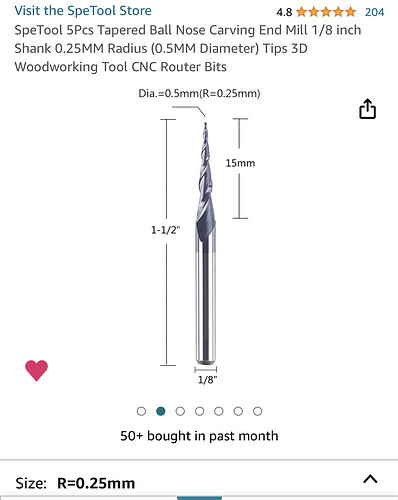

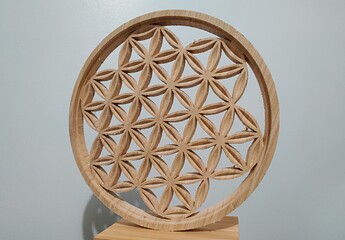

I’ve made a few relief cuts and as they do turn out ok, I am most certainly missing some detail, and I think it’s in how I am entering it into the system. This is the bit shown below. I grabbed a few to learn/practice relief work. Thank you for any help!

Carbide Create does not support tapered ball-nose tool geometry — you can enter this as a ball-nose tool, but you will need to only use it in projects where there will not be surfaces so vertical as to be cut away by the taper.

Thanks Will-

Is there a bit you recommend using for detailed relief cuts? I knew CC did not support ball nose, wasn’t sure if maybe we had a database with others who have successfully entered this bit in the past.

Carbide Create supports ball-nosed tooling — it’s this tapered geometry, with the taper included in the cut which isn’t supported.

I’ve had good luck with Garr Tool’s long reach tooling, and I’m sure the Precise Bits folks have something suitable.

Missing detail with that bit would be from a setting.

As @WillAdams stated above, the drawback of using the tapered bit is that the taper will show on vertical walls of the carve.

But you using a 0.5mm ball should bring in all the surface detail, depending on your settings.

Appreciate the reply. I do not think I am entering it correctly. Im at work or I would screen shot the entry parameters I have been using. It just seems I’m not getting the detail I should, and wasn’t sure if maybe the community has built a database for all bit entries over time. I am interested to see how others would enter this bit for doing relief work-

When you can, show the project and your settings for the tool and path. Plenty of people here that do the same thing you are trying and with a good bit of success.

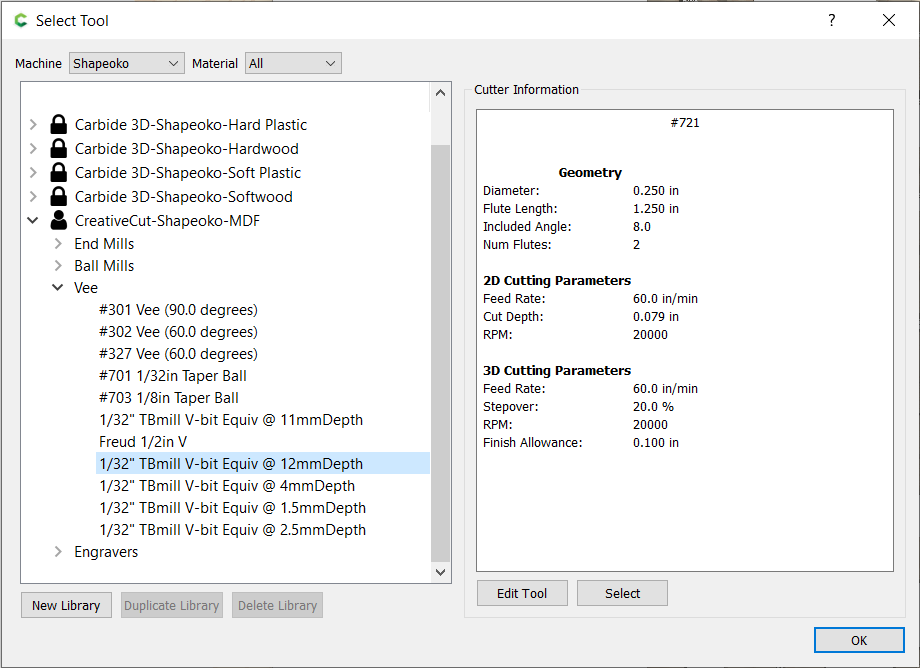

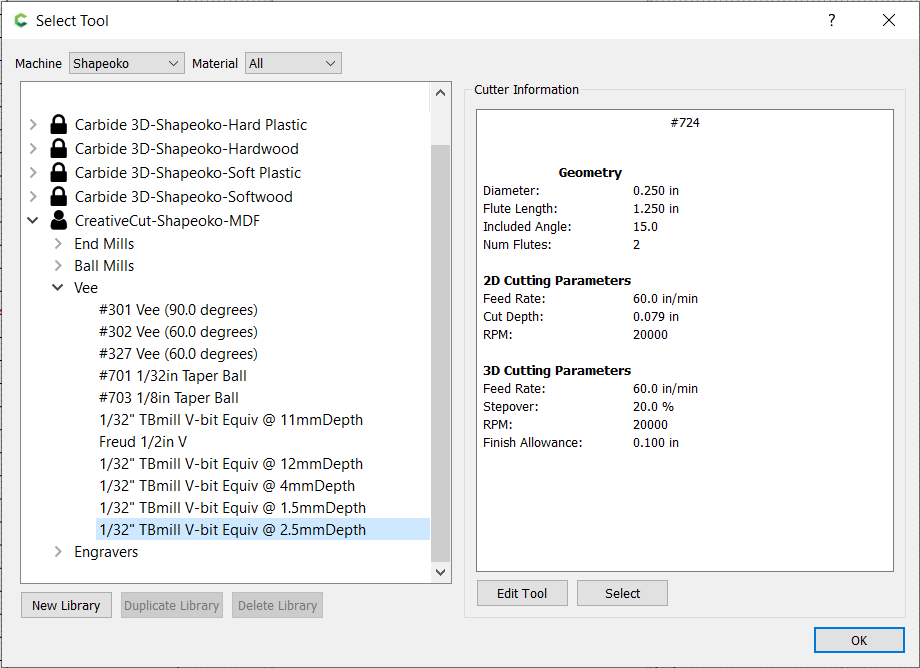

It is possible to use tapered ball nose bits in CC entered as a V-bit with an Angle set for a certain depth of cut or stock thickness so the program calculates more /less the proper offsets.

It can be tedious, depending on what you are trying to accomplish, but it can work pretty well & give you a more accurate view in the Simulation as it constrains the upper portion of the taper bit to the shape.

For this test design, I used my 1/32" taper ballnose which has a 6.2 Degree taper to it. But at 12mm depth, it is similar to a V-bit with an 8 Degree angle. As you approach closer to the tip of the taper ballnose, the equivalvent V-bit angle will increase.

I hope one day CC will support taper ballnose cutter geometry, but I get that it is significantly more complex to program & calculate - I also have & use MeshCam which does support taper ballnose tools, but it can take much, much longer for it to generate toolpaths.

I suppose what would be really nifty is if CC could export into MeshCam. I quite like designing things in CC & I like the different toolpath & supported tool geometries in MeshCam - they just need to be able to talk to one another.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.