Hi folks,

We’ve just upgraded our SO3 to the 1.5kW/110V VFD controlled spindle that’s available from MySweety on Amazon. We picked this specifically because it has a 65mm diameter so it’s a drop-in replacement for the Makita router. So far it’s been awesome as many will report and was very easy to setup (SO many forum posts on this… look around).

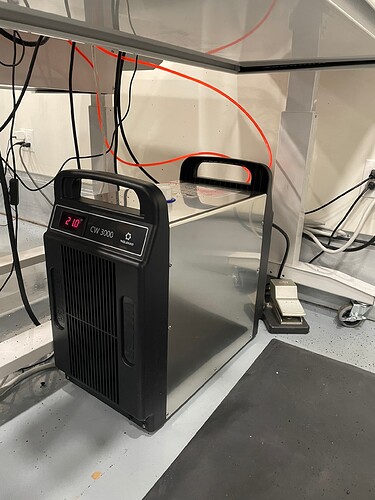

The one thing I was unhappy with was the pond pump cooling system. Seemed a little Mickey Mouse. We run a business here didn’t want to screw around with DIY pumps and computer radiators. Instead, we opted to use a low-cost commercial chiller that is commonly used for cooling laser sources or TIG torches. This (very crappy) one cost about $140 and has it’s own little reservoir, flow, and temperature alarms!

We used 2 gal of pre-prepared TIG torch coolant. A little pricey, but nice to have something that is made for this purpose.

The inlet and outlet fittings were 3/8" hose barb. We adapted them to the 1/4" tubes from the spindle with a hose barb adapter and a short length of PE tubing. Low pressures, so no hose clamps were needed. Just heat the PE tubing up a bit to slip it over.

We run this spindle cutting plastic all day, 5 days a week, with an 1/8" single flute end mill at about 19K RPM and the temperature sits at about 21ºC. Honestly it’s probably over-cooling it a bit, so we might hook up our new SO4 to it in series. Plenty of capacity and a nice pro looking piece of equipment.