Maybe this is already a thing, but I hadn’t seen anyone doing this and thought I’d share. Simple setup and seemed to work pretty well.

I wanted a way to check diagonally multiple times quick while adjusting and tightening and stumbled into a little method using a laser tape that seems to have worked pretty well.

I have this little Bosch pocket laser tape measure and it’s accurate within 1/16th. This tape has a feature where it just keeps updating the current measurement without pushing the button so as you move it, it updates live. It’s a nice feature.

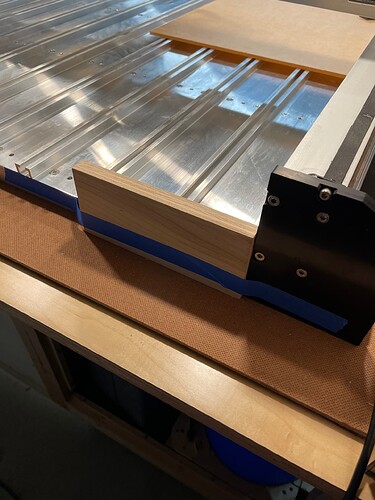

I glued some little 45 degree blocks to some small scraps of ply that I had around. taped them to the back corners of the machine, tight against the side rails. Then I could hold another block against the front of the rail, to create a corner, and then seat the tape in the corner, aimed at the block. I put some painters tape over the rubbery backside of the laser tape so it could slide/pivot easily in the corner.

Doing this I found that my machine was 1/8” out of square. Double checked the results with a tape and the 1/8” off was accurate.

Loosened everything up and made the adjustments. Squared it to an equal measurement. By rotating the laser slightly in the corner i dialed into square by making sure I got equal measurements across the roughly 1” face of the little wedge. Pretty easy with that live updating i mentioned. I checked it multiple times it as I tightened.

I didn’t fully trust it at first, but I checked square against a tape on other frame points through the process and it seems to be at least as accurate, and maybe a little bit faster?