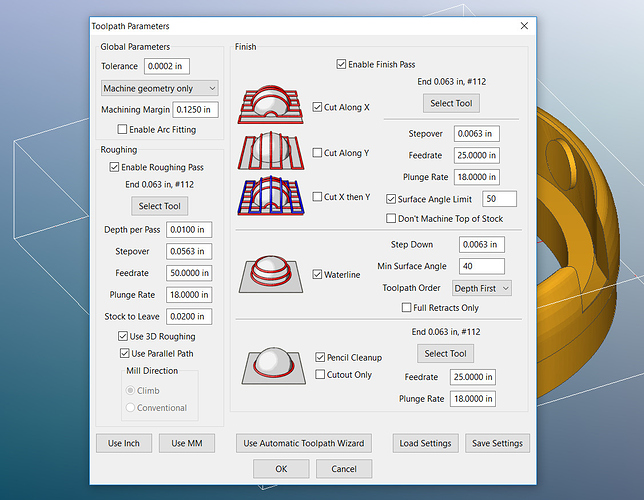

With a design for a wristwatch incorporating wooden pieces in the case, I arrived at this solution after much trial and error. One machined piece is a delicate ring of stabilized walnut which slips around the main steel case, and the other is a thinner one which goes inside the case as a bezel around the dial. For those interested in milling wood down to fine limits (so many snapped pieces…) I’ve included the toolpath settings. I wasn’t sure at first whether the stabilized wood would behave more like a hardwood or a plastic, given the resin. In the end I worked from acrylic pre-sets and tinkered with the values until the Nomad produced reliable results.

Here are the two wooden pieces before and after sanding and finishing with CA glue:

Forgive the arty instagram shot but you can see the very fragile section of the pieces where they thin out to fit over the steel lugs - very prone to snapping and pretty much the bane of my existence

I had initially imagined using a flip jig to machine these pieces from both sides, but ultimately just machined from above and completed the reverse by hand with Dremel and files.

I had initially imagined using a flip jig to machine these pieces from both sides, but ultimately just machined from above and completed the reverse by hand with Dremel and files.And here’s the finished watch. An exterior walnut inlay around the case and a smaller interior piece around the dial…