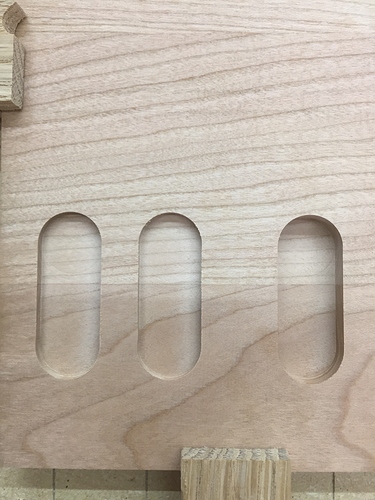

Well a busy weekend and I had a chance to do a couple of tests. But I must admit I made a mistake. The 1/2 inch bit is really a 5/8 inch. To be exact Freud 04-0136. I did download Gmack’s spreadsheet and found it helpful. So I took Carbide’s 1/4 em guideline for hardwood as a starting point to determine chip load and Julien’s suggested chip load range . I settled on a chip load of .0016 rpm 19700, feed 63ipm .2 stepover and plunge of 15 (wanted to be rather cautious on plunge). I attempted two doc at 1/8 and 1/4. I got nice clean cuts no chatter. The only thing I found was that the 1/4 doc was too much for this bit. I lost steps after 1/8 down into the plunge and ended up with a 1/8 slot. As you can see I got good results but it’s not an ideal bit for plunging.

I also discovered that you cannot use the probe to zero x and y for this bit because CM only has a few selection for end mills and thinks in this case that the bit is a 1/4 inch. That should have occurred to me but the Spock in me was sidelined by the emotion of the moment. Any how I could not find a way of adding end mills for the touch probe.  . @WillAdams I think that would be a wonderful addition to CM. I added some pics here so you could see the results and chips and bit. If someone sees something off let me know. Thanks for everybody’s help and advice!! My dust boot arrived today and should have my hose andconnectors by end of week I hope. That’s what I will be doing this weekend!

. @WillAdams I think that would be a wonderful addition to CM. I added some pics here so you could see the results and chips and bit. If someone sees something off let me know. Thanks for everybody’s help and advice!! My dust boot arrived today and should have my hose andconnectors by end of week I hope. That’s what I will be doing this weekend!

3 Likes