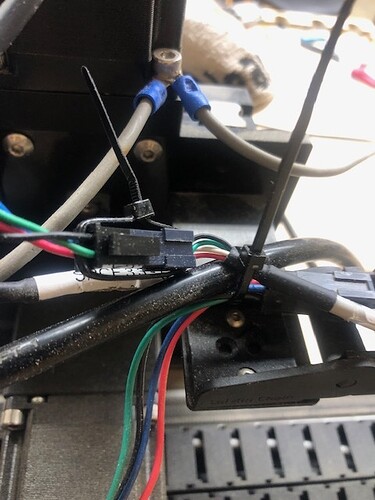

Has anyone seen this issue on their machine (Shapeoko 4 XL) like this where the wiring harnesses connected to the motors are causing the motors to stop working and lose synchronization with the other side during vibration or movement? Carbide3D sent me a new wiring harness and motor but after installing both, I’m experiencing the same issue on both sides of the machine. I’m waiting to hear back from them but curious if anyone has experienced a similar issue. My machine has been down for about 3 weeks now and it’s only 2 months old. Here is a video of the issue.

If you have verified that the wires appear to be correctly crimped, this is what I did.

Yes, I hate the connectors said Sam I am, like green eggs and ham.

Yes, I removed the AC cable.

I’ve replaced the majority of the connectors on my machine with soldered splices and heatshrink. I did have another gremlin pop up with the homing switch for X axis a couple of weeks ago. That will be replaced here shortly.

The only issue with hard wiring is if you have to replace something you have to cut and solder the new part in. That is ok for someone that knows how but most people do not know how to do that. Connector issues have been a C3D plague since the SO4/5 came out. Maybe they need a different connector or a different person making the connections/connectors (manufacturing).

There should have been a connector at the motor, or sensor, and a connector at the controller. Any more than that, and you’re asking for problems. And a reputation you don’t want.

I think a long run single wire with connectors at the ends makes more sense in most situations, but I also see the wisdom of doing it the way they did. Making the parts modular should assist in replacement for the consumer. That being said, the connectors could be of a better design.

I have had issues with the X and one of the Y motors losing a phase a few times on a 4 XL I’ve only had about a week. I’m not sure if the problem is the connectors or the crimps at this point. I’ve tried putting some contact cleaner on the pins and am hoping this will fix the problem. Losing a motor in the middle of a job is a potentially catastrophic problem. Like others, I wonder about the wisdom of so many connectors in terms of reliability.

The Shapeoko 3 had those problems also.

I removed all connectors and soldered the connections except at the control board. No stepper problems since the soldering.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.