I have removed the set screws on each Y axis stepper motor. Y left is on the flat part of the spindle and should be ok according to the posts I have read here. Axis R I cannot tell if it is on the flat spot. seems to be a spot of grease in the hole and I cannot tell. How do I spin the piece where the belt is on separately from the motor spindle. I do not want to start prying things apart that were never meant to be apart. Yes, I know there is a name for that piece but I have been writing this for a half hour and am tired of thinking about it.

original problem is outside circle cuts are all off center. any help with the set screw issue or any other ideas or places I can research on how to tune this machine in really good would be extremely appreciated. and, if you are a big help I will probably bother you all the time so, beware… thanks again!!

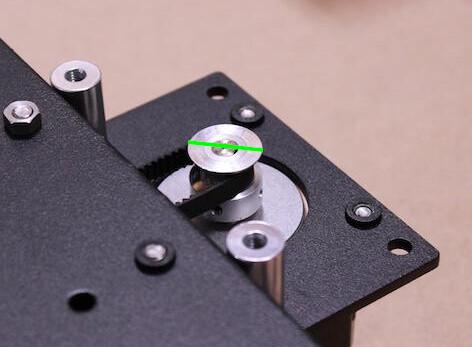

That would be the pulley, and while in theory after removing both setscrews you should be able to rotate it on the motor shaft, in practice sometimes it’s just stuck there, from normal use or initial tolerances. If after you removed the two setscrews you cannot rotate it with your fingers, then leave it alone, put the setscrews back in, and retry some jobs after drawing a line with a marker like so:

(this is the picture for an old Z belt-driven axis, but you get the idea)

If the line stays aligned after your cut, they you know that the pulley did not slip on the shaft and you can stop worrying about it.

If it did slip, then you should be able to go back and pull the pulley out of the shaft, gently (but possibly with some effort…)

Can you share pics of those outside circle cuts that are off center ? It may not be the set screws.

yup…pulley…anyway, I will try the line thing and run a quick job. otherwise here are two outside offset cuts on catchalls. both of them are offset.

removed 2 set screws from pulley. one screw is not set onto the flat part of the spindle. I am unable to rotate the pulley freely from the spindle for some reason. Both set screws are removed. how can I rotate the pulley without rotating the step motor spindle? was previously told that I should be able to easily remove or rotate pulley in order to set screw on flat part of spindle securing it in place.

Have you been able to confirm whether the pulley actually slips on the shaft, with the marker line trick ?

If it did not slip, well you’d better leave that pulley alone and just re-insert the set screws. Sometimes the pulley is stuck on the shaft due to mechanical tolerances or normal use, and it’s a pain to remove it (and you don’t want to risk damaging anything while trying).

I did not run a test because I want the problem fixed properly not just tighten down the screws and hope for the best. I obviously do not want to try and pull the pulley off forcefully but, it needs to be done right. sorry, dont do things half ass so I will just continue searching for an answer.

My point was that it may not be the pulley causing your problem, and the marker tip was just a way to determine that. If you haven’t already, contact support@carbide3d.com for a more appropriate answer.

I will let you know how the test turns out and I will go from there. thanks for the help!

come to find out, the second set screw will not even thread back into the pulley. It did not look right when I unscrewed it the first time so maybe there was an existing problem from factory. I asked about getting a new steppper motor or at least a phone call. see how it goes I guess. again, thanks for the help…it at least got me in the right track.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.