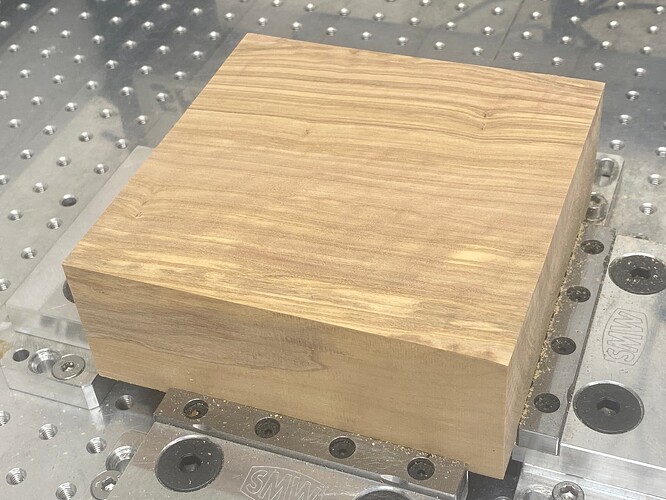

This was a commercially derived STL file carved into olive wood stock sized 140 x 140 x 50mm. Cutters used were Amana 28mm three flute surfacing cutter, 6.35mm two flute x 32mm straight cutter for roughing, 0.25mm ball ended cutter for finishing. Carbide Motion was used for all cutting operations on a standard sized Shapeoko SO3

Toolpaths were generated in Carveco Maker. The olive wood stock was very slightly cupped in a single direction and it was surfaced using a pocketing toolpath and an Amana 28mm surfacing cutter. It had been roughly bandsawn to 140mm square so that it could be held adequately with a pair of modular vices.

Roughing toolpath - carved with an orbital toolpath from the workpiece centre outwards. This used a 32mm long bladed cutter on a 6.35mm shank, The cutter toolpath used a 3.175mm stepover and 1mm of stepdown. The feed rate was 1000mm at 10,000rpm.

Finishing toolpath - was Carveco’s circle in a box toolpath from workpiece inside to outside. The cutter was a 0.25mm ball ended cutter with two flutes on a 4mm shank and an included angle of 9.8°.

Wood block was hand sanded with 3000 grit sandpaper (no sanding was required by the carved design) and a single coating of beeswax. CNC machine is a standard sized Shapeoko SO3 with a trim router. HDZ upgrade just purchased and it will be installed when the new 2.2kw spindle (ER20 collets) and VFD have arrived.

pictures: