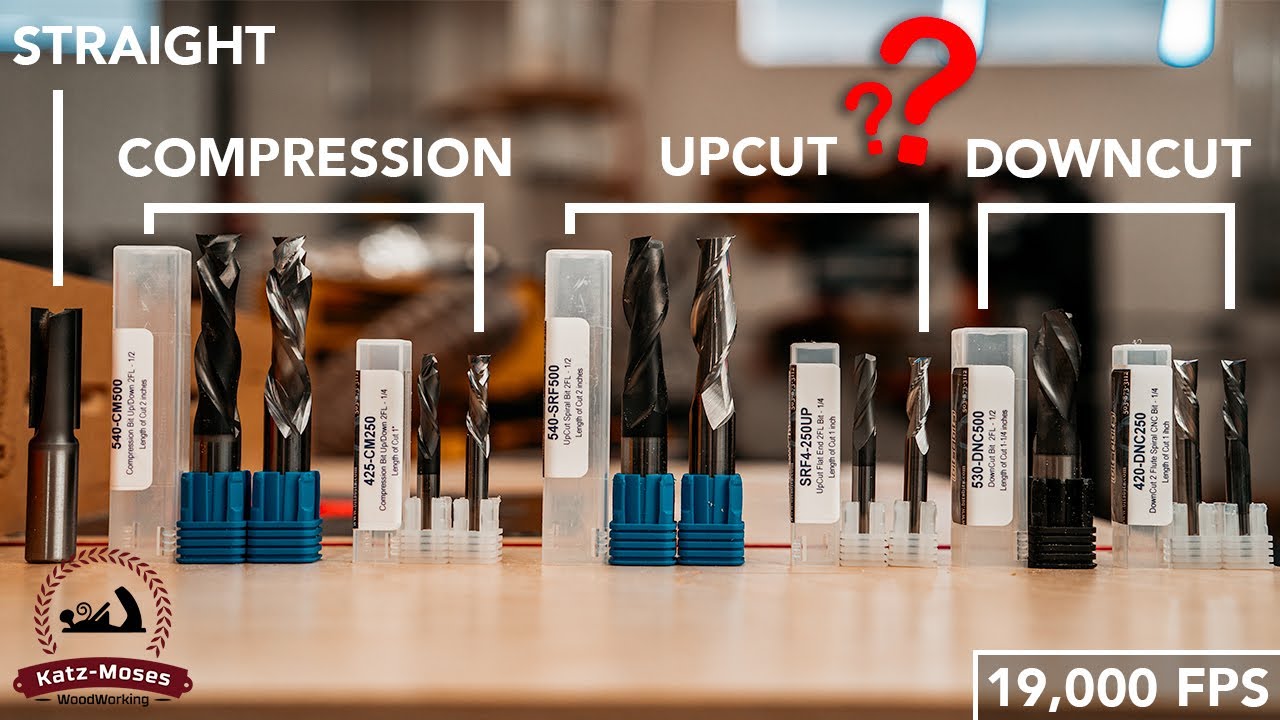

I was lurking around on youtube and found this interesting video about the uses for Straight, up and down spiral bits and compression bits. Lately several posts have been made about compression bits and this video gives a good tutorial on the different types of bits and their uses for CNC as well as general woodworking.

There was a tool vendor on the Unofficial Facebook Group who made an interesting compression geometry tool adapted to the limits of smaller machines — it had a very short compression section, so that the initial entry and depth of cut would be greater than it.

Super jealous of their slow-mo video setup…great video

Recently I have seen several posts about trying to use compression bits. I found this explanation about using compression bits on cnc machines.

CNC routers need bits. They determine the kind of processing you can do, the resolution of your finished designs, and how fast you can move through the material. They come with cutting edges that pull up or push down (sometimes both), they have square or shaped ends, they are made for speed or accuracy, and they come in diameters from a pinpoint to over two inches for standard CNC routing.

For the topic of this blog, we are covering compression bits in all their glory.

What is a compression bit?

A compression bit is the combination of both upcut and downcut spirals. Typically, a compression spiral has an upcut single, double or triple flute at the tip of the cutter, approximately one third of the cutting length. The remaining two thirds is ground to give a downcutting shear.

By combining both geometries, you achieve a win/win situation. The bottom of the material is pulled upwards while the top of the material is pushed downwards thus eliminating the risk of damaging the laminated surfaces. When run at full depth, the bit leaves a sharp, clean edge on both sides of your workpiece.

A compression bit can be a little more expensive than standard router bits, however here at AXYZ we recommend them as an essential tool when processing double laminate wood materials.

Why use this over a conventional upcut or downcut bit?

Compression bits are used extensively for cutting double side laminates such as melamine or plywood. These tools can also be used on natural woods where edge finishing is a problem with standard spiral tools.

A dedicated up or downward spiral may only give a good finish on one side of the material if the material is laminated. Where both sides of the material require the best possible finish, a compression bit is your best solution.

How do I use this tool correctly?

While compression bits are the tool of choice for cutting double side laminates, it’s essential you use the tool correctly.

The cutting edge of most tools are on the side of the tool, therefore a direct plunge into the material will be fine for your standard upwards tool as the waste material is lifted out of the cut line and into the extraction system.

However, for downward spirals and/or compression tools, it is best to ramp into the material. This approach stops the swarf from compressing at the bottom of the tool and causing extreme levels of heat. This heat will damage the cutting edge of the tool and the work piece.

For those who are unaware of the difference between plunging and ramping, it can be explained below:

Plunge: A vertical Z movement directly into the material.

Ramp: While the tool is driving into the material, it is also moving forward along the programmed path.

The diagram below shows the correct method for cutting a compression bit:

For all your router bits, parts and consumables, head over to CNCshop, our one-stop shop for everything CNC.

Author: Abdullah Umair is an application specialist for AXYZ, a global manufacturer of CNC router and knife systems. Abdullah has covered many areas during his spell at AXYZ to ensure he has gained holistic exposure to both the needs of customers and the functionality of the machine.

One thing he doesn’t mention in the vibration comparison between straight cut and the spiral cuts is that you need a minimum depth of cut for the helixed bits to produce that consistent cutting force, there needs to be a part of the spiral cutting all the time for the forces to level out like this. That’s fairly easy on wood but harder on other materials.

This topic was automatically closed after 30 days. New replies are no longer allowed.