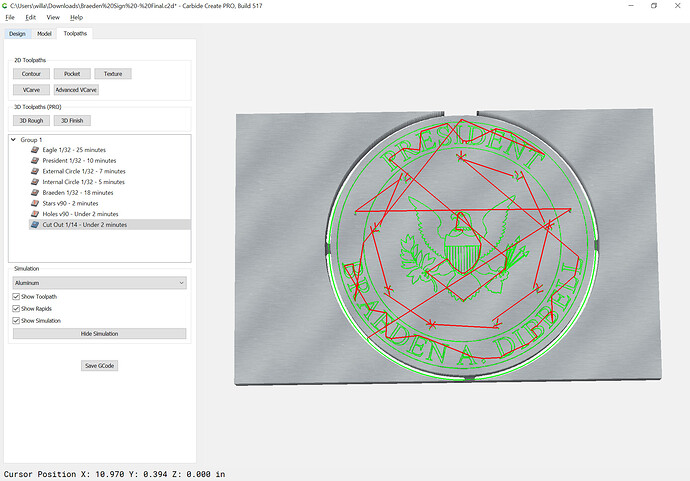

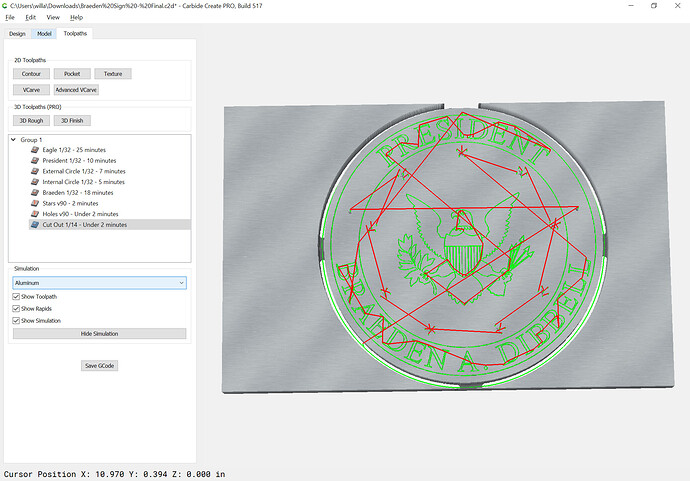

Tabs should be explained in:

https://docs.carbide3d.com/assembly/carbidecreate/video-tutorials/#holding-tabs

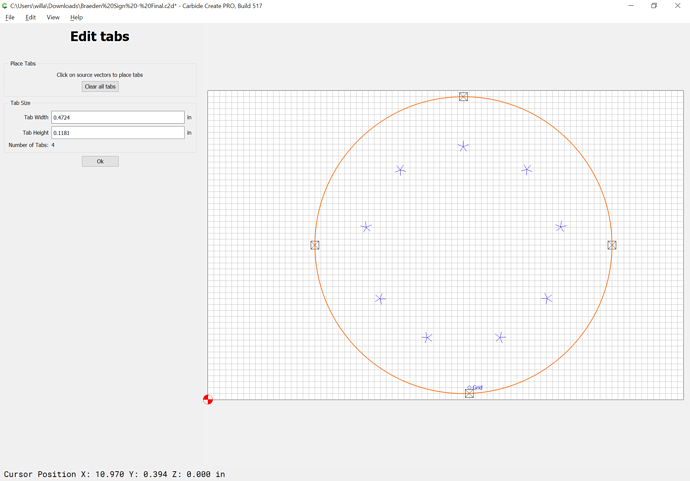

It’s simply a matter of assigning their width and height to match the holding necessary:

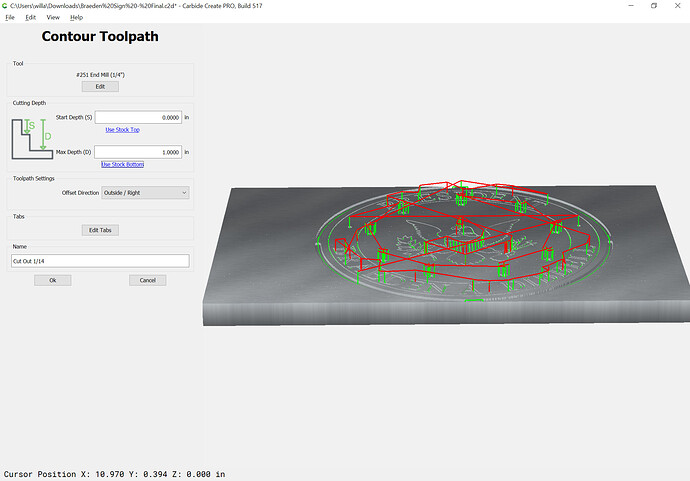

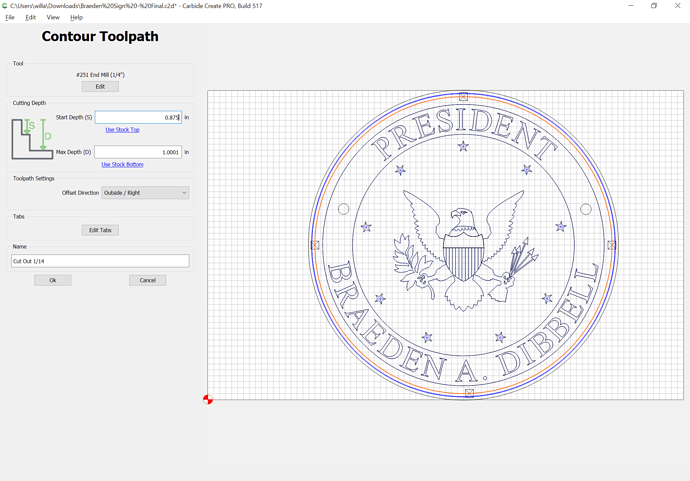

and of course, they only make sense for cuts which go all the way through:

If you want them larger, just increase the size:

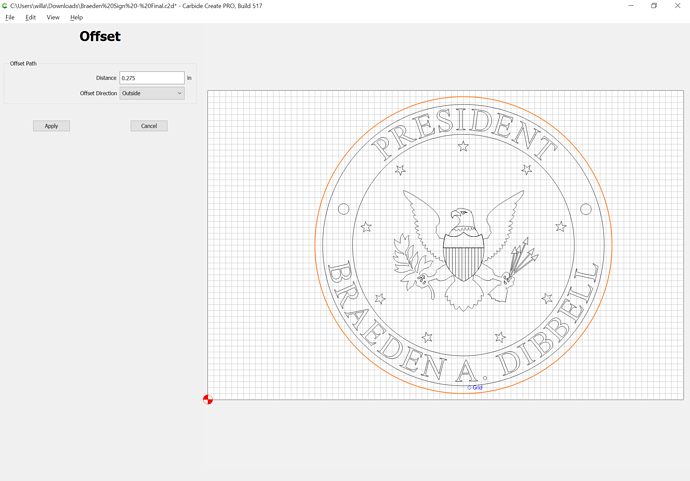

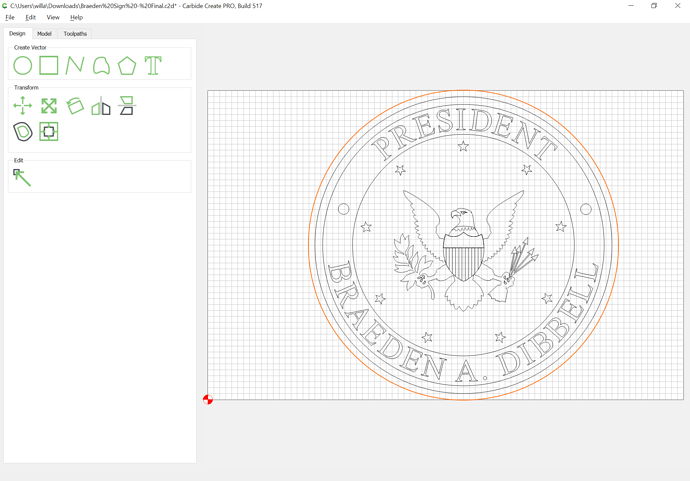

Note that it’s best to not cut a slot just as narrow as the endmill — that results in 100% tooling engagement, so add offset geometry ~10% wider than the endmill you are using;

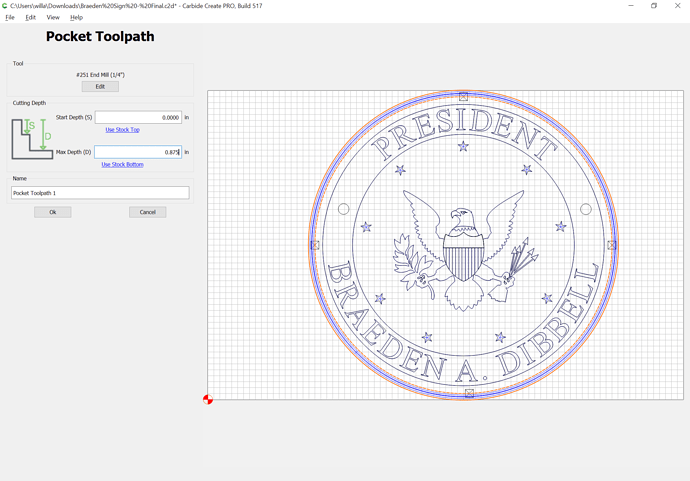

Cut as a pocket down to tab depth:

Move the pocket above the profile cut:

edit the profile cut to start at the bottom of the pocket:

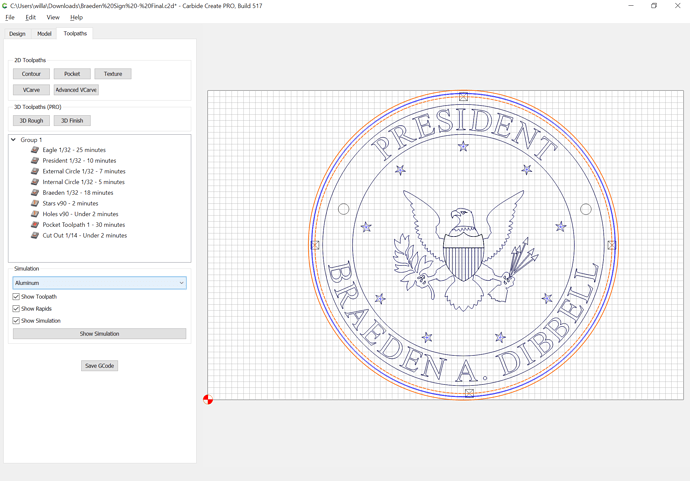

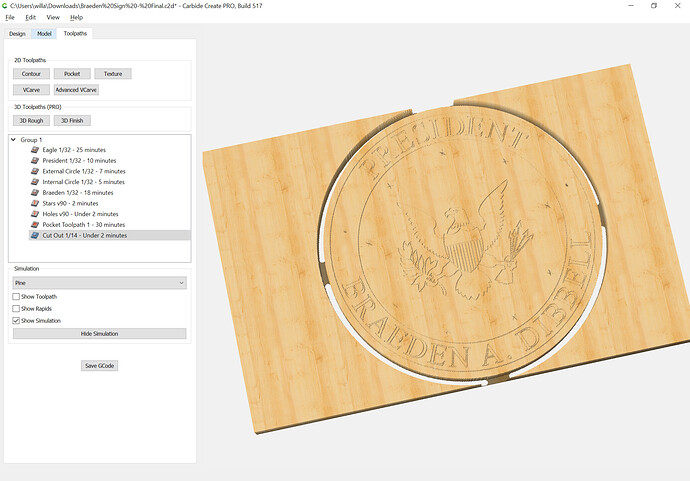

to arrive at:

For an optional improvement, increase the out profile offset distance and add a second offset of the original geometry to create a roughing clearance: