I cut out some treated 2by material for ouTdoor furniture. I changed to 150 percent over and increased router speed and it got better but still made a lot of strings. I used default settings for softwood. The bit was a 1/4 2 flute 60 degree helix. In cc I used #201 bit. Any advise.

What is your feed rate and and router speed setting? With that information I could probably help.

The treated stuff tends to be wet and stringy like that — any chance of stickering it and setting it aside to dry for a year or two before cutting?

Well I did cut it up and plane it and then stickered it for two weeks. But time marches on. It was much dryer when I cut it than when I originally cut it up. Unfortunately the only treated wood you can get right is all new. Old stock have been depleated. I replaced the floor in my trailer and I bought it in the fall and stickered it all winter and it was still wet. I had covered it when we had rain and uncovered when it was sunny and shuffled it around. At some point treated wood will just have to be wet/damp.

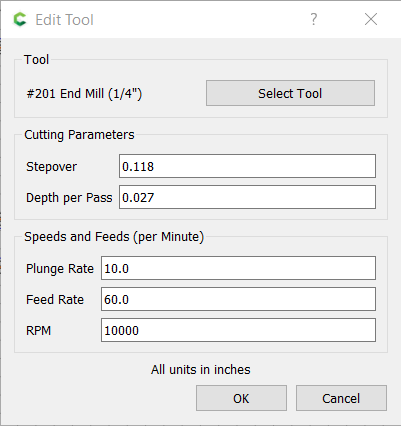

As for F&S I used the default settings for Shapeoko Softwood. Here is a screen shot of the tool

I have a Dewalt and it will not go that low so I set it to 18000 and finally after increasing to 150% I set it to 22,200 rpm. At the higher feed rate and rpm the project cut better. The cuts were acceptable but was just wondering if I could improve the cuts in the future.

My first reaction is to significantly increase your chip load. The Carbide Create recipe wants you at 60 IPM, 10000 RPM which is a .002" chip load. At 60 IPM, 18000 RPM you are at a .0011" chip load and at 90 IPM, 22200 RPM you are at a 0.0014" chip load. I routinely cut aluminum at 80% stepover, .025" depth and a chip load between .0015"-.0025". You should be able to push much harder. I would imagine that a bigger chip would also improve stringing issues as long as you have good chip evacuation. To match the CC recipe with your Dewalt, you need to increase your feed rate to 96 IPM and set it to 16000 RPM. I have never cut treated wood before so take my advice with a bit of salt.

Thanks for the replies.

This topic was automatically closed after 30 days. New replies are no longer allowed.