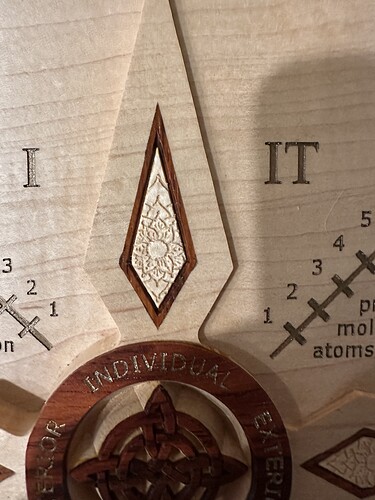

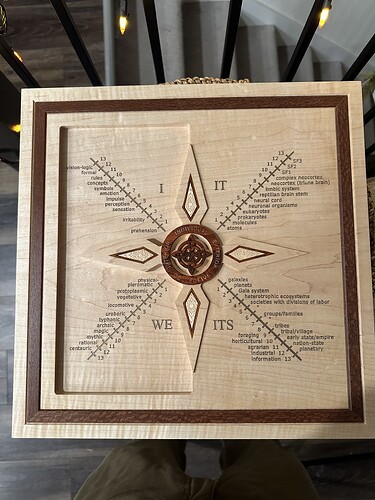

Hey everyone, I’ve been making these pieces for years, and am suddenly running into challenges with my inlay vcarves that I just can’t seem to figure out. It’s a classic problem people have run into before, and I’m wondering if we have a standard troubleshooting protocol to help get it solved.

The issue is, I make these diamond inlays, and as you can likely see, the corners of the inlays are getting ever so slightly blown out during the carve.

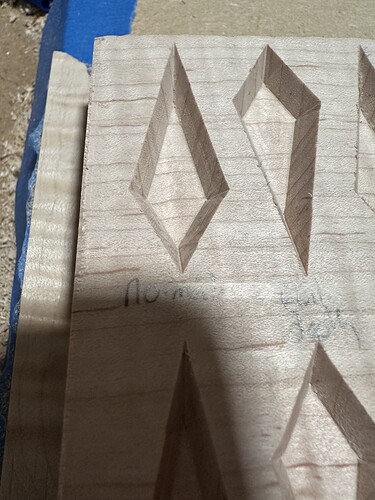

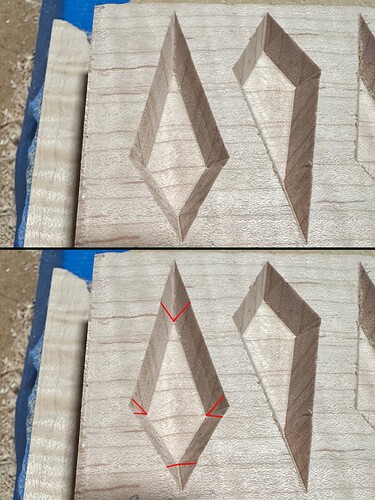

Here is a couple image of the “naked” carves I made during a test, so we can see what’s happening.

The issue seems to be with the final pass, when the spindle “lifts” in order to sharpen the corners. It seems as though the bit is going ever so slightly too far in each corner, going slightly past the sides of the diamonds that it just carved.

Here is how I am doing the carve, using vector aspire:

-

Surfacing path (let’s say .015)

-

Tool path 1: 1/8” bit, clearance pass, start depth of .015, flat depth of .2”

-

Tool path 2: 60 degree vbit, start depth of .005, flat depth of .2”

-

Tool path 3: 60 degree vbit, start depth of .015, flat depth of .2”

As you can see, I am backing off of the start depth by .01 in my second step, in order to minimize possible deflection in the final pass.

And yet, I am getting the results in the images above.

Here is what I’ve done to troubleshoot and experiment so far:

-

checked tramming. I am very slightly heavy on the left side, but not enough to cause this issue I think.

-

replaced old vbit with brand new 1550 bit, to make sure i didn’t lose the sharpness of the tip

-

updated post-processor in Aspire

And here are some experiments I tried:

-

Test 1: standard carve, with a vbit pass depth of .1

-

Test 2: same, but with final pass depth of .2 for toolpath 3 (so it does it the final pass as a single pass, rather than two)

-

Test 3: same as test 2, but set vbit angle to 61 degrees

-

Test 4: same as test 2, but set vbit angle to 59 degrees.

Anyone have any suggestions as to what else I should try? I really want to get these inlays as precise and consistent as possible!

Also I am using the 1550 vbits bits from Carbide (are they called 302 now? Same bits?) I’ve never had issue with these bits, so I am confident that they are sharp and the 60 degree angle is accurate.

Any help would be appreciated!