So kids are busy in the fields somewhere on my land, wife is happy in sowing room - Que exit stage left for Dad to the workshop (old school Batman transition music)

Now i have had a big tidy up inspired by both John’s from NYCCNC and Grimshaw Knives podcast series "highly Recommend from both a technical and philosophical standpoint as well as workflow etc) Podcast series is called “the business of machining” on Spotify must be able to get it elsewhere.

Anyway back on topic, John Saunders said today in the podcast “learning needs to be real” long story short he is talking about prototyping or learning new techniques adds far more value when done for instance on a widget you are trying to sell rather than a circle.

One of the topics the two Johns were talking about today was tooling tray, (automated) that resonated with me, and i decided that i will adopt this Pallet approach, i.e. a pallet for each job or thing i do, this is achievable because i am a hobby / semi productioninst (if there is such a word ) i can afford to do this because costs are still relatively low

Inspired by this and wanting to have a bit of fun, i set myself 30 mins to design as many things as i can, that had to conform to the following:

- Functional that i can use to increase / decrease my workflow

- Use a toolpath or technique that i have not fully understood or delved into

- Finish “thing” must be right first time - no revisions or tweaks

- Total tooling and design time must not exceed 30 mins

I found this to be very refreshing and i have a little notepad full of things to follow up on.

I would welcome other peoples additions to this thread to see what you come up with, but be super strict 30 mins or less folks…

I did 4 things today 5 in total, but one failed the right first time measure.

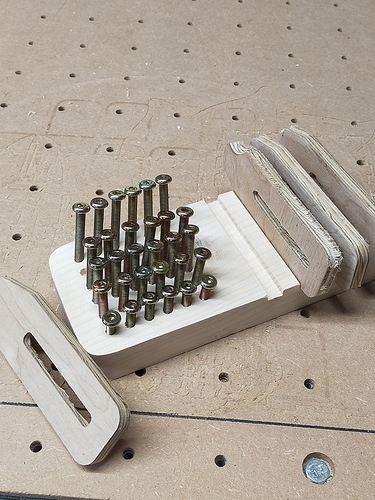

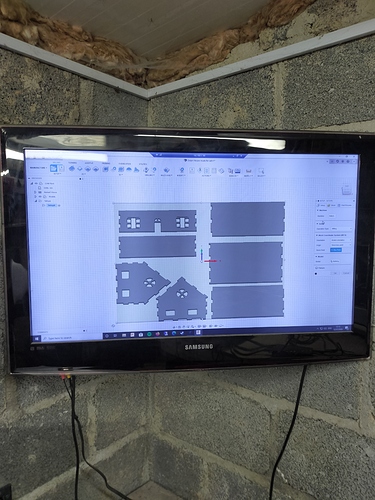

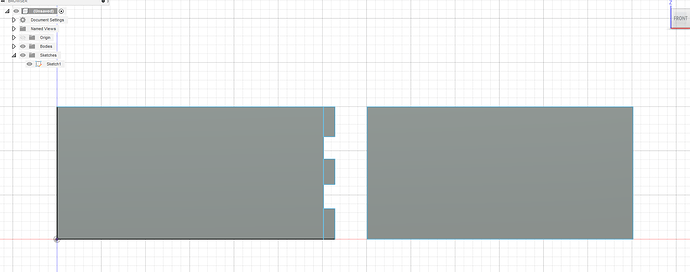

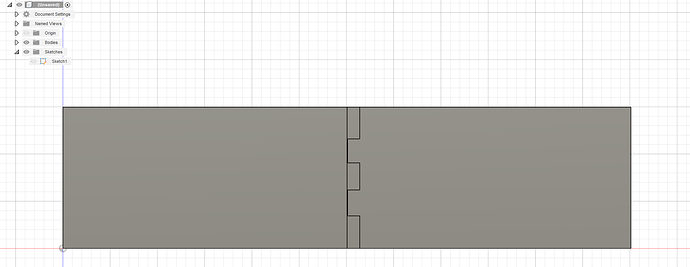

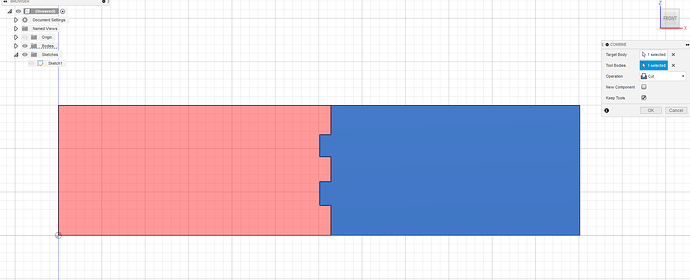

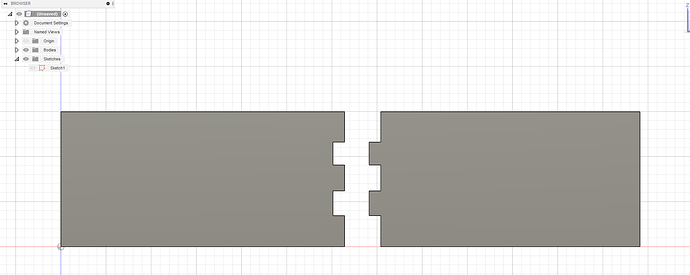

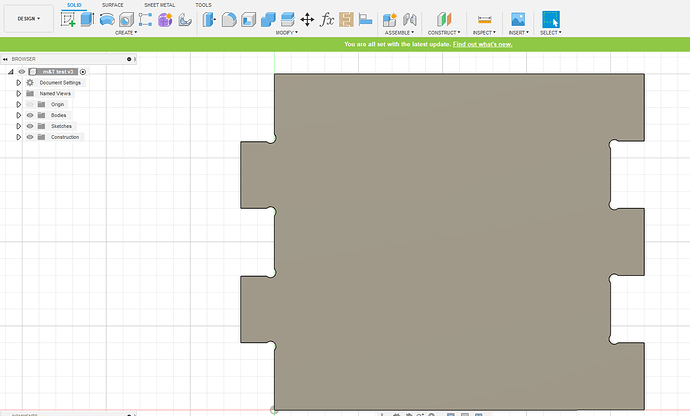

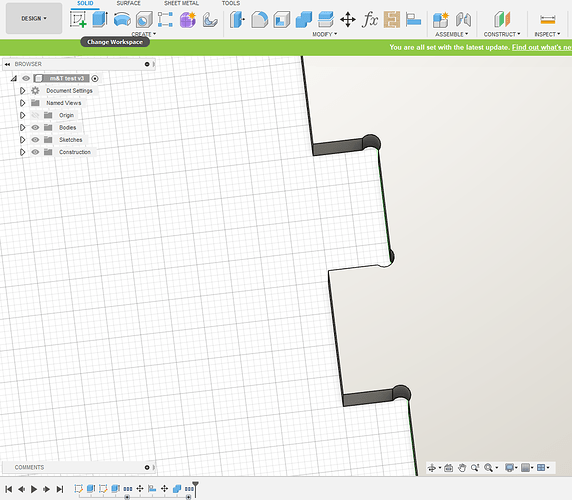

First - clamping pallets

Design concept - have a pallet that is setup for different clamp amounts, typically i use between 2 to 10 clamps to hold things down, and get frustrated that sometimes i cant find them quickly, either because i broke some and said “i will make some later” or the magic drawer has swallowed them!

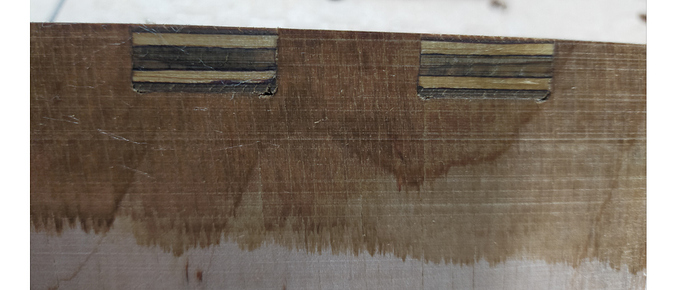

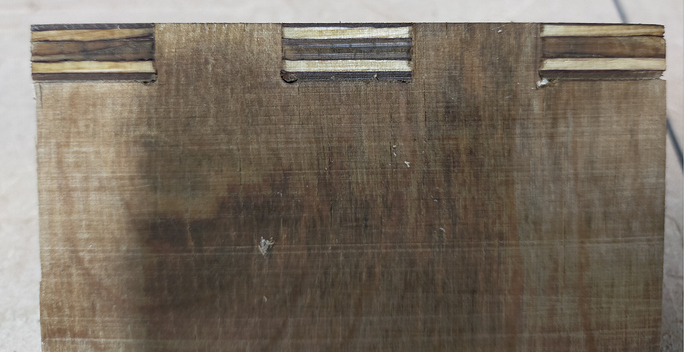

The pallets are all setup for different sizes, and the 6 different screw lengths are catered for too. i have decided to do three pallets for 4, 6, and 10, clamps and screws. The one below is the 6 clamp version, need more clamps, the keen eyed of you should be able to tell why in the first pic

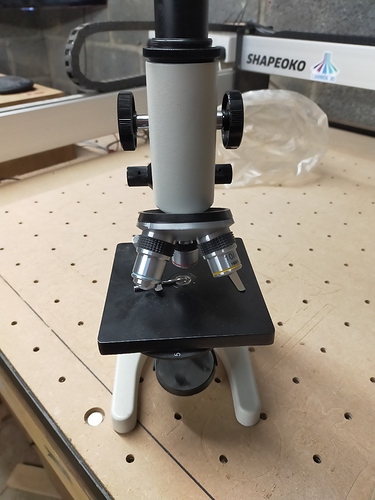

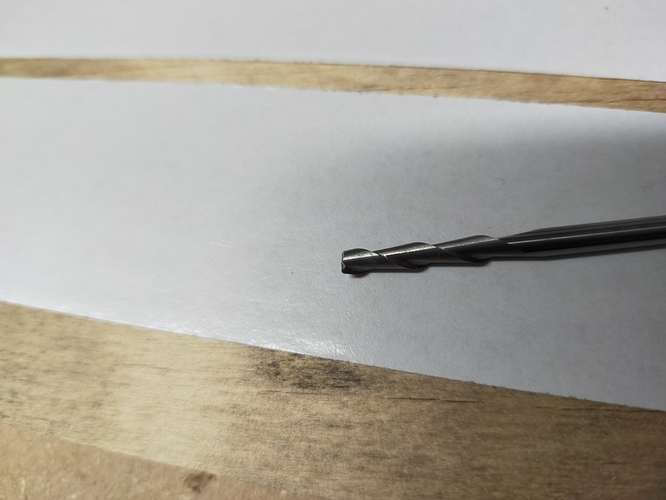

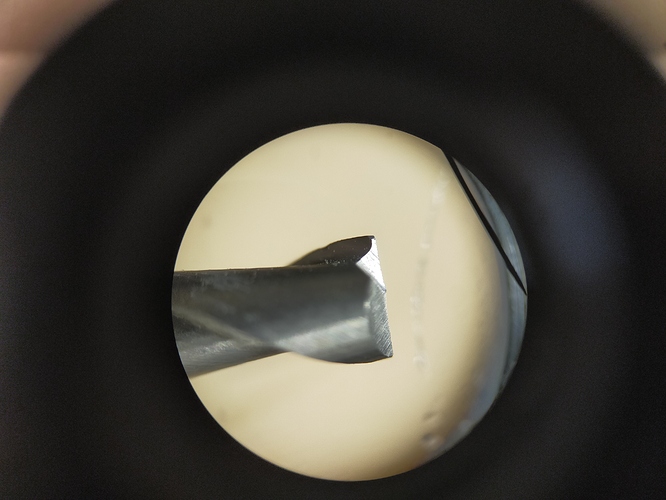

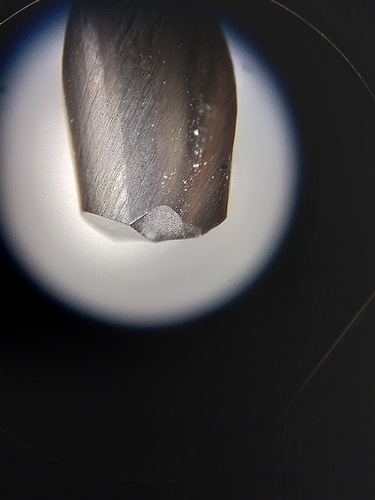

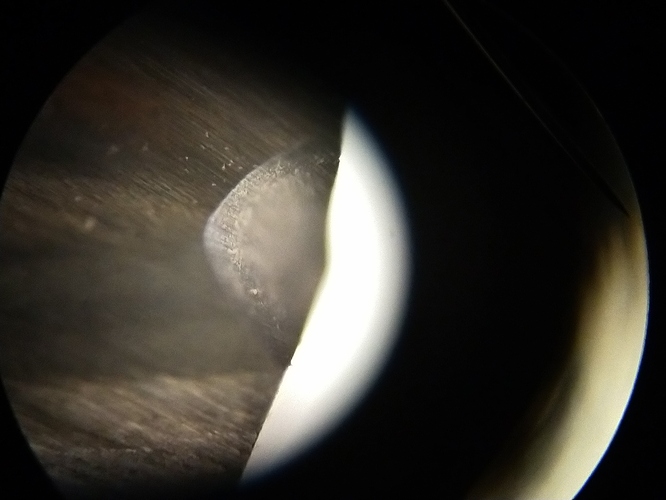

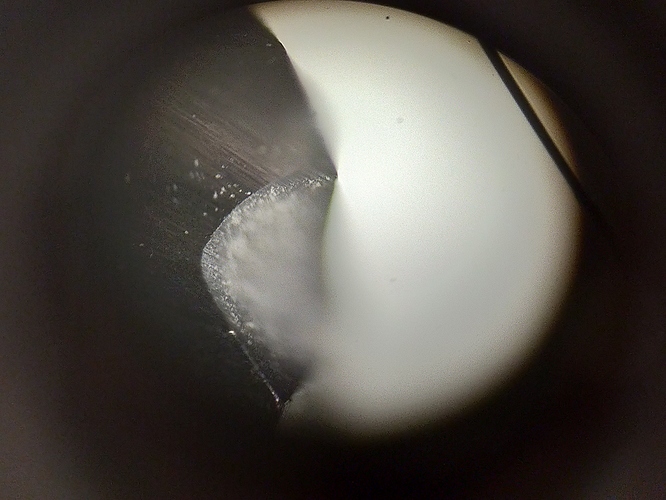

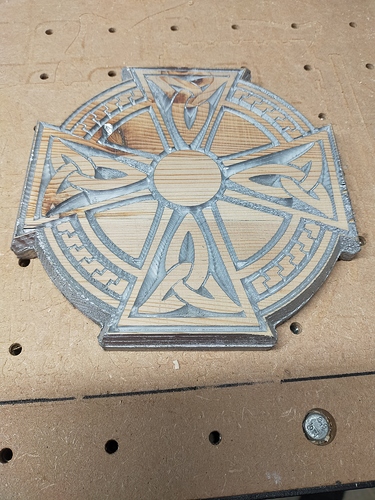

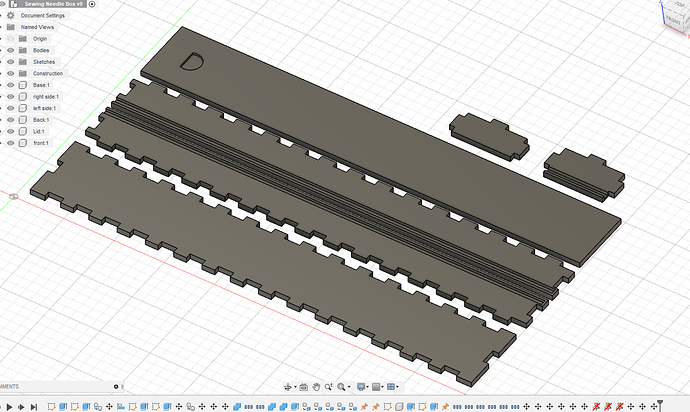

Second - Cutting tool tray type

Design Concept - i want to have these all setup for different job types, for instance a sign making tool tray, HSM tray (clearing Tray), this tray then has all the tools i need to do that job.

The way i work is from left to right, the left tool is the current or active one, i then move left to right if i have duplicates of the tool, shifting left once a tool decommissioned from cutting (hope that makes sense).

This has helped ensure i am getting 100% out of the tools instead of 10% on one and 30% on another. These then sit on my shelf and i pull and work from the tray throughout the Job workflow.

Was really interesting today i felt like it increased my speed, but that might just be because it was new.

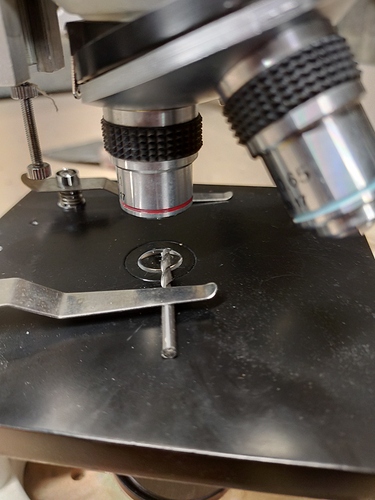

! !Third - Cam Clamps

Design Concept - never used them before, simple design and needed to make sure would work with my current hold down spacing, not much more to say other than, after trying them, i think i need more than 2 to make this work as it was over torquing (moving the part) with the other clamps i have as above

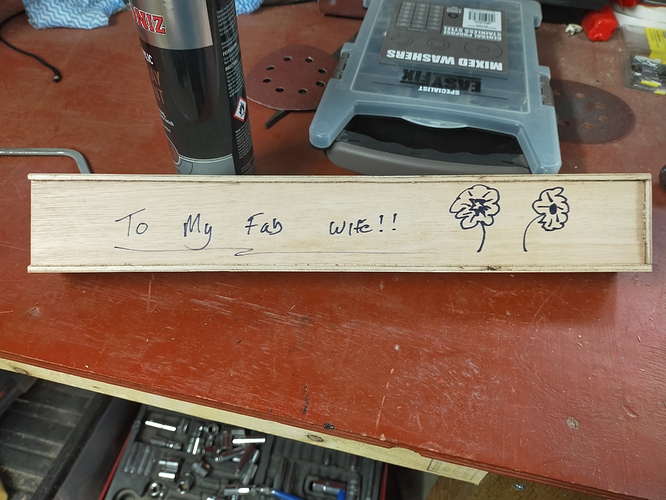

!Forth - Bell safety!!

Design Concept - As posted in my contest 10 entry (shameless plug please vote for me Or actually Vote for one of the awesome entries our community submitted) but for those who do not like marketing

i was frightened by my wife coming into the workshop while the machine was on and i had my Bluetooth ear defenders on listening to music), it was funny but also could have been dangerous as it really made me jump, and if i was doing something on the machine, this might have been a serious.

I installed a outside doorbell we had lying around on the ceiling as you come into the CNC room within the workshop, i felt it needed a Do not touch me type thing that obviously pople will notice and touch lol, created a nice little sign tag to go onto the bell string to prompt people to ring, am in the process of creating a sign for the door explaining the rules of entry when machine is on.

! !I found this interesting and challenging give it a go, you too can +1 level up your Critical Thinking.

Jon