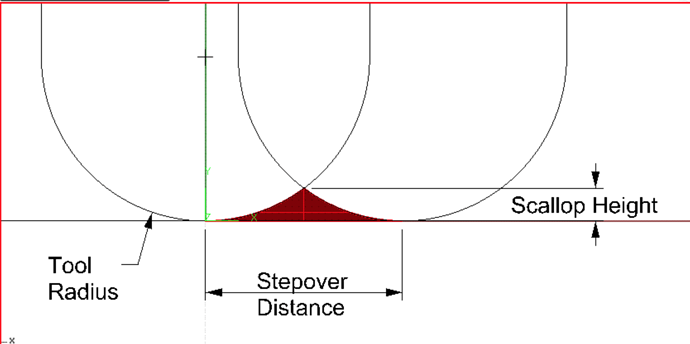

My thought are that you are not well versed on 3D cutting (sorry). Let’s talk about Ball End Mills. They should only be used in areas where you can’t use a Flat End Mill (e.g. Curved/angled and rounded surfaces). When finishing with a Ball End Mill you need to worry about the cusp (or scallop) height, and that is controlled by the size of the end mill, the nose radius and the step-over. I will use a step over as small as 0.001" to as large as 0.010" but doing so takes a LOT of time (which is why you try to only use the ball end mill in areas that you really need to. Additionally, there is a sacrifice for time and that is bad surface finish.

So my recommendation is to use a large flat end mill where ever you can, a small flat end mill is the other areas and finally, use the largest ball end mill to machine the other areas as needed.

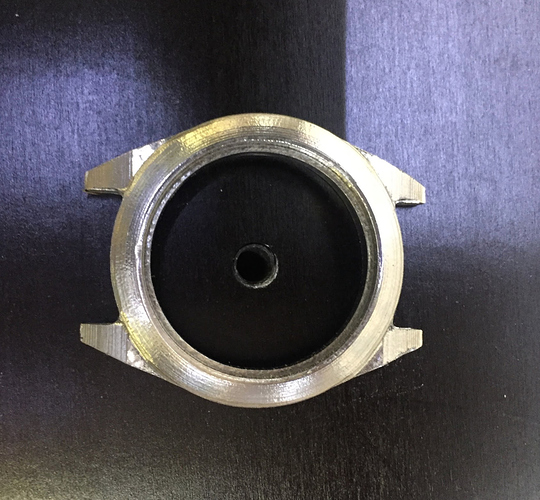

Here is an example of some stainless steel I cut on my Shapeoko usinf a 1/32 ball end mill with a 0.003 step-over (Before and after polishing.)