This may not be new to many people, but a hint when surfacing wood, especially less brittle woods like pine:

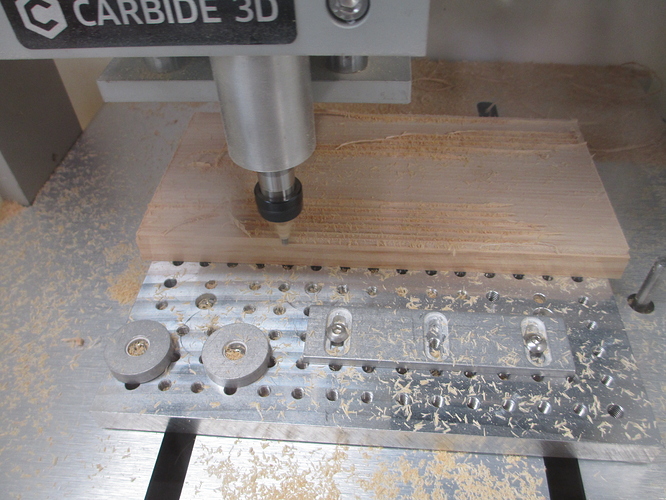

Instead of running surfacing passes parallel to the grain like this:

leaving strings of long grain rather than chips, the strings being harder to clean up, not fully separating from the work, and tending to wrap around the tool

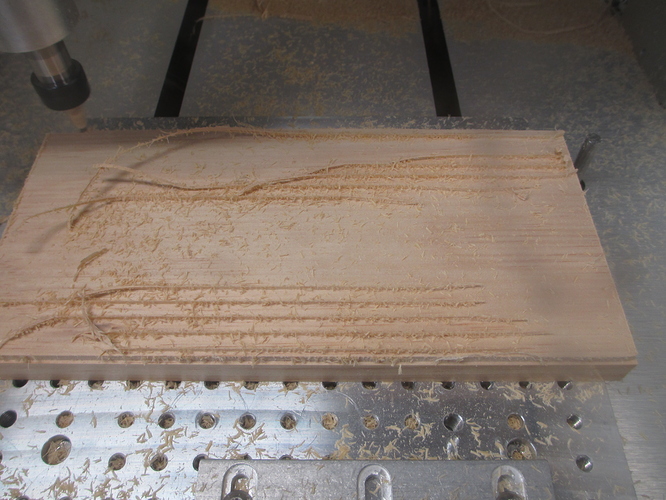

run surfacing passes at a small angle (this is about 4 degrees) to the grain

for controllable, easily broken chips.

The reason not to run perpendicular to the grain is dust control. You will get a lot more of the fine dust that will plug filters, hang in the air, and coat everything, if you run strictly cross grain. The goal, like with metals, is small, manageable chips rather than long strings or dust. This is especially relevant when using smaller tools, like on the Nomad, where many, many passes are required for large surfaces.

Care to guess who blew the setting on a job today?