I created a file to clean my 4x2 wasteboard with my dust collector and sweepy. It’s a polyline contour path using a custom tool with a 2.5" diameter. What kind of feedrate should I use? I set it at 250, but I’m looking for advice before I fire it up. Lol

Very big bits need to go fast. They also need a shallow depth of cut. There are a lot of posts about people trying to surface cherry here on the forum and they get burning. So go fast the bigger the bit. A big bit has a lot of surface engagement and creates a lot of heat.

I’d run a slow one initially just to watch it and make sure it’s going where you want while making sure the Z is correct. Once you have proofed the program then I would say crank it up and find a speed where the vac is picking up whatever is missed. I know the fastest my 5 pro will run is 200ipm though

Update your carbide motion.

They changed machine settings to 275ipm a year ago.

Weird because I’ve certainly updated CC in that time and have programmed a 1/4” em to run at 225 and it only ran 196ipm. I’ll have to look into it

I’m not using an actual bit. I only have the sweepy attached to vacuum up the dust on the wasteboard hands-free

I think you’re just going to have to try it once and see how it works. It’s going to really depend on the size of the dust particles and material. Ex. If you’ve cut a lot of aluminum recently, you might need to run the cleanup program slower to convince those chips to get sucked up. You can always just leave the program at 200 inches per minute and then use feedrate override to slow things down. No need to export multiple programs for each scenario.

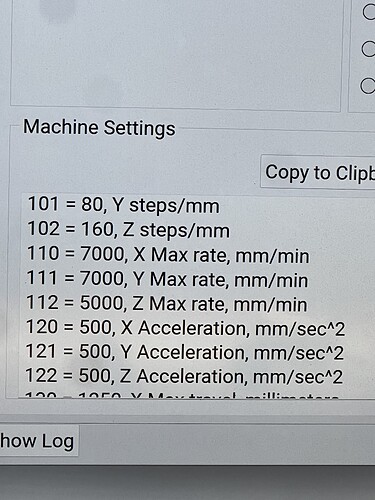

Side note, @Pmckh , the top speed is technically 5000 mm/min, so 196.8 in/min.

All S5’s have the same settings. The speed limits can be modified by the end user up to ~40%, but if you run into any issues, the first thing support is going to do is ask you to change them back.

Thanks for the side note Winston, 196ipm is exactly what I’ve seen

Has carbide reduced the standard grbl speeds since cm635? Because these are factory speeds as far as I am aware and that were reviewed in my support case from 8/20 by like for a strut issue.

I have yet to mill aluminum, but chip weight is definitely something I’ll watch for in the future. Thanks!

For the record, 200 ipm might be faster that you want to push an endmill, but it’s a slow-ass vacuum cleaner. Lol

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.