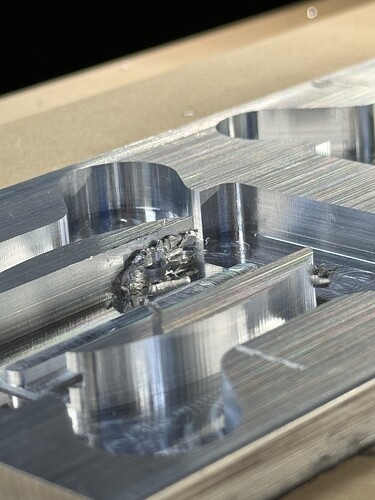

Hopefully someone here can lend some assistance on feeds and speeds for running this bit on the Makita Router on my Shapeoko 5 Pro. The manufacturer has no listed speeds and feeds that I can find on their site for this particular bit. I am trying to cut a slot in 6061 aluminum and had my speeds and radial DOC horribly wrong on the first attempt. The tool is a Datron T-Slot bit (SKU: 0068423) 10mm cutting width. The first attempt melted the aluminum to the bit so obviously that was far too fast and deep. Anyone here with experience cutting a key slot or T slot?

10mm is about 3/8", so for 6061 I would go with 8000 - 10000 RPM, and a 0.010" - 0.015" stepover.

I would not try to cut the whole slot at once, unless I was using an adaptive toolpath & some good air assist / coolant to get the chips out of the slot.

Another consideration is the start point. I doubt you want to cut this like a keyhole where the tool plunges to full depth & then cuts out the slot.

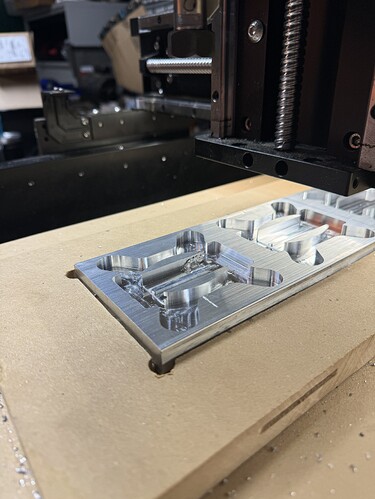

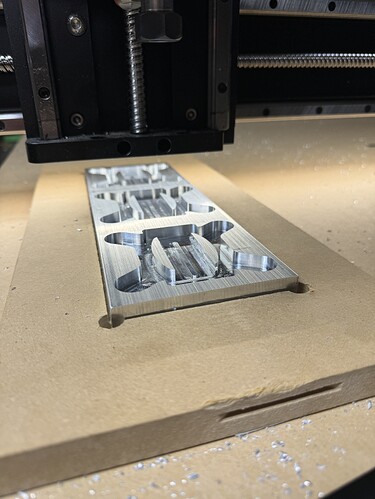

Looks like you added pictures while I was typing. So you’re adding a side slot to that vertical wall?

I cut retaining ring grooves with a similar cutter in aluminum at 10000 RPM, 40 IPM, 0.010" stepover

@Tod1d thank you for the quick response. Yeah I messed up with the depth of cut, for sure. I will try your recommendations this morning and see how it turns out. It was a mess for sure. Not only did the aluminum melt but the angle of the flutes pulled the bit and Z down as it went into the material and made the mess even worse. Do you use a conventional cut or climb cut with your bit?

I typically like to use climb cutting for all finishing paths.

I use mist coolant on all my aluminum cuts. It’s a tiny amount of coolant. I have to hold a piece of paper to see if it’s working. It just slightly dampens the paper when it’s at the right mix.

What is your coolant setup like? Do you have a HDM?

Yes, I have an HDM. I have an airbrush pump ( Amazon.com )

And a cheap misting system ( Amazon.com )

If I had to do it again, I would go for a slightly larger pump for a bit more pressure, but this one works fine. I would just like a bit more pressure to use as an air only system with more pressure to blow chips out.

The mist system works great. I put a drop of Loctite on the mist adjustment screw as it’s really sensitive, and added a smaller orifice to get a better mist distribution.

If this was wood, conventional wisdom is to hog out the middle with a straight cutting bit and multiple shallow passes and use the t-slot bit to do the minimum. However, I could be misunderstanding the situation.

I would love to do that but you can’t get an end mill into the area. It’s very tight and requires cutting a 2mm deep slot into a vertical face.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.