New to this so I hope this is in the right placed.

I recently bought an XXL w/T Trak and while the T Trak serves its purpose I found while playing around with different size wood that configuration isn’t always beneficial.

I’ve thought about moving the wider waste board to the outside but not sure if it would make that much more of a difference.

My question with that in mind has anyone installed threaded inserts in conjunction with T Trak system?

Yes, folks have done that — I believe Josh Tenny did for his Pro.

Appreciate it Will, have to check it out.

With threaded inserts and/or Tee Nuts you can use cam clamps. I find the cam clamps very useful over the tall t-track type hold downs. I use a combination of large and small cam clamps and also use the Tiger Claw and Gator Tooth clamps as well as the stops from c3d. If you go to myerswoodshop.com and in his blog he has plans for free for cam clamps. You can also buy them from his etsy shop.

For cam clamps you need to measure your wood thickness. Then subtract .5 inches and make the large washer hole this depth. The reason for this is you have to add your wasteboard thickness and the .5 inches to get bolts that will not bottom out on the factory wasteboard. As I surface my wasteboard I add washers in the large washer holes to keep my bolts from bottoming out. I start with 1.25 inch bolts and two washers. This makes sure you do not bottom out your bolts. After a couple of surfacings you may have to get shorter bolts. But with a 3/4 inch wasteboard and a .5 inch hole from the bottom of the clamp you have a known measurement for the bolt.

Thanks. Will have to keep all that in mind.

Currently working in CC to set up the holes in T-Trak MDF. Hopefully I can get right, I plan on keeping the boards in place and not milling all the way through. Drilling out after might add time but I will have to take them out to install the inserts anyway.

Wish me luck.

If you are putting threaded inserts in be sure you get the threaded nuts below the surface so you do not hit them with a surfacing bit. You can take them out if you replace the mdf in the future. One tip is to slightly champher the holes from the top before inserting the inserts. This makes the inserts start straighter. I personally like Tee Nuts better but which ever you use make sure they are not too close to the surface.

FWIW, I think the easiest way to do this would be to set up one file w/ the origin at the top left (after machining pockets for parallels or something to set the origin square to the machine) which includes an operation to cross cut the stock completely, then make a full set out of MDF from the box store, then swap them in place after installing the threaded inserts.

I did, too. I’ve attached the file, if you’re interested.

Wasteboard - 25mm Complete v2.c2d (595.9 KB)

I think I have this right not sure. I modeled it from Myers 32 X 32 with modifications for the T-Track system. I used 10" for each piece of MDF and 0.728 for extrusions (2). The thickness is just a round number for the time being (didn’t feel like pulling the filler to measure).

Any input would be greatly appreciated in advance. This actually the first time I even remotely tried to design anything. T-Track with T-Nuts.c2d (1.1 MB)

If you have not made your wasteboard yet please read the doc I prepared for considerations for a wasteboard. The specifications for a Shapeoko for an XXL is 32 X33. But part of that is off the front of the machine and is impractical to make a 32x33 spoil board. Plus you need to surface the wasteboard and you cannot get maximum travel to level your wasteboard and not leave ridges on the sides and/or back.

Take at look at my doc and see if you can adapt the advise for your wasteboard.

spoilboard_considerations.pdf (1.3 MB)

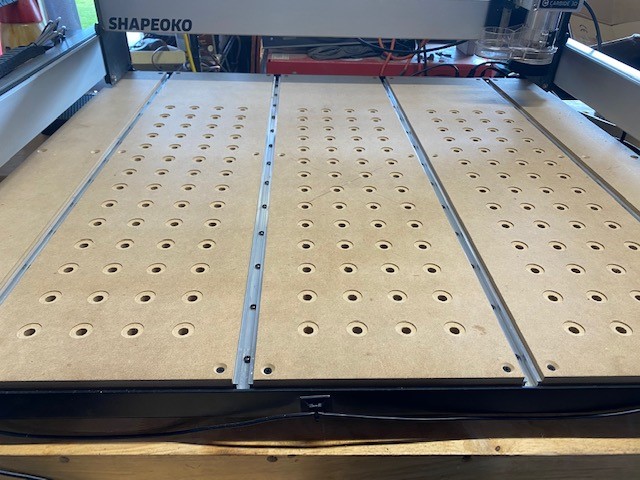

The actual measurement of my layout is less than 32” wide by 32” High.

Looking at the Sim you are actually seeing the bottom of the MDF fillers. There is a pocket to recess the T-Nuts.

All of the design only includes the 3 fillers and 2 extrusions that make up the center area of T-Track from Carbide.

I did read your PDF, good info.

Well I finally got it done, just waiting for the nuts to arrive.

This topic was automatically closed after 30 days. New replies are no longer allowed.