I just purchased the shapeoko 4 XXL and im currently awaiting its arrival. Before it arrives I want to build a workstation for it. What would be a good table top height for a man thats 5’ 7"?

Normal table heights vary from 29-33 inches. The table height plus height of spoilboard should determine height for you. Personally I like sitting in front of machine to operate. Some like workbench height to stand and operate. So first determine your preference. Then subtract height of machine. I built a torsion box under my SO3. I have about 8 inches in front to lay tools and calipers. Also consider if you will later make an enclosure.

Everything in my shop is on wheels so I can clean or do maintenance. So add height of wheel

The legs were purchased on Amazon: Amazon.com

I think they were about 42" long/high.

Buy one or make one, start from the ground and work up.

The most important thing is that you start with a solid, level base. These casters will allow you to move your machine around for cleaning then retract the caster putting your machine back down on solid ground. One other thing people sometimes forget is that if you move your machine, you should re-level it. Lets face it, our garage floor was put in by lowest bidder and is as wavy as a potato chip.

I’m 5’8" and I liked below 40" for my SO4Pro XXL. Normal bench height is cool if your bench is 24" deep… but at 48" deep… it was too high for me. Reaching workholding all the way at the back required a stool for me above 40". Personally, I would go 38" max for an XXL. The table I just made for my soon to ship SO5 Pro is lower with a 34" table height. Getting all the way to the middle and back of a 4x4 machine necessitated even lower height for me.

I’d second that, for an XXL, I’d suggest measuring what height you can comfortably bend at the waist over to reach all the way to the back of the machine from the front, subtract about 2" for the machine spoilboard and go from there.

If you’re going to put the machine on wheels or in the middle of the room then things may be different.

Thanks everyone…between everyones comments i going to go with a shorter height and the retactable casters.

One other reason for my table being the height it is, is because I’m enclosing a shop vac, dust collector and vacuum pump under it. ![]()

I had some of those. I finally bought the plates like you have. I could buy one set of wheels and move multiple pieces of equipment. Without those plates the wheels are a trip hazard.

I’ve lost the link to purchase those casters. Can you help? ![]()

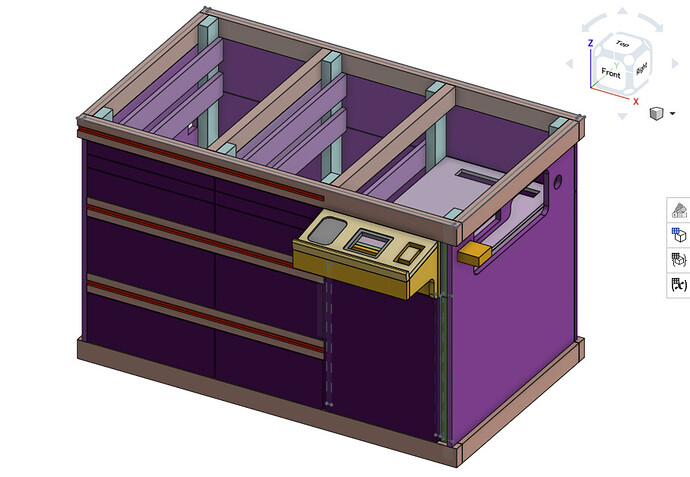

I’m 85% through building a new table for my Shapeoko 4 XL, but big enough to handle the Shapeoko 5 (2x4foot) when I eventually upgrade. Build in storage, control panel/E-Stop, etc. All the lessons learned from a year of a Frankenstein bench.

Here’s the model, without the top 3/4 inch. It’s 38 3/4 tall, with caster like you guys have been showing, so it sits flat on the floor. It’s 35 inches deep, and 5 feet wide. Happy to tell you more about it if anyone’s interested.

Here’s the ones I got:

DOZAWA Retractable Workbench… https://www.amazon.com/dp/B08CKZN5ZQ?ref=ppx_pop_mob_ap_share

You can get the plates separately?

The set comes with plates, but you’re thinking like me that you an switch the casters to other tables/tools in your workshop by just adding plates to them.

Perfect. Been keeping my eyes open for something like these for a while now. First plate mount option I’ve seen.

Will be adding these to my HDM setup.

The plate work well. However there are several manufacturers of those casters and although they all look alike be careful that they fit your existing wheels before drilling holes in your stands. Also be sure to read the directions because there is a particular height they have to be fixed at so the wheel will cam up and cam down properly.

Indeed. I have a similar set on my workbench, non-removable but not an issue since it’s legs are well inboard of the bench ends.

My table is two bathroom vanities from Home Depot screwed together with a 3/4” top riding on some 4” locking casters.

You really shouldn’t need a level table. Or even a level machine. I suppose the machine will have slightly more trouble cutting at the extreme margins of its ability if it were upside down or perpendicular to the ground and having to fight gravity a bit.

Otherwise, what matters is flat and square. You want your machine surface flat (which is what flattening the wasteboard is for and it will also ensure the wasteboard surface is parallel to the gantry) and you want the machine square.

As long as your table is PRETTY flat and MOSTLY level you won’t have any significant issues.

I was at the Rose Parade, so couldn’t look up what I bought.

Anyway. Here’s the sink base:

2 back to back makes a 4’ x 5’ table. I tore off the toe kick so that with the 4” locking casters it would be right about counter height. I have the Shapeoko 3 XXL so this gives me a small area off to the side for a Raspberry Pi with a touch screen as my Carbide Motion controller.

There’s a 1/2” ply on the bottom and 3/4” sanded ply for the top. Screwed it all together in a few hours with limited help. Casters were the biggest pain.

The middle doors are big enough for a 16 Gallon 5 HP Rigid Shop Vac for the Sweepy. I cut a flush mounted power strip behind the Shapeoko to plug in the controller and the router (but you could feed those down below too if you prefer).

I plan to cut a hole and connector in behind the Shapeoko for the Sweepy to connect to, but I just pull the hose out through the doors for now.