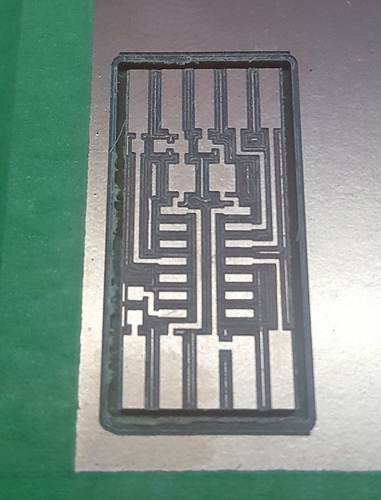

I finally got around to running a test cut using Carbide Copper on my Shapeoko 3 today, and I thought I’d post some pictures and a few notes.

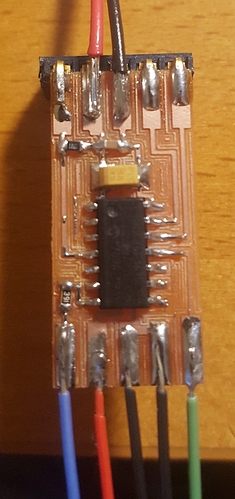

This simple button board was designed in Eagle 8.2.2. I plan to use it when tinkering around with an Arduino, so the 10k resistors are pull-down resistors to keep logical low consistent.

I missed the initial sale of FR1 copper clad, so the board I used is FR4 from Mouser.

I cut it on my Shapeoko 3 with the DeWalt 611 set to 3.5 (~21,000 RPM) (not because I know what I’m doing, just because that’s what I set it to… and it worked fine.)

I used Carbide Motion to run the job, and I manually split the gcode file into three files, for the etching, drilling, and cut out, so that I could re-zero the Z axis during tool changes.

As @jimmo mentioned in another thread already, having a super flat waste board is crucial, and variations in the thickness of the PCB can cause some trouble. I resurfaced my waste board, then attached the PCB, and still found .002 variation. I increased the size of the traces and clearances slightly [1] and then deliberately zeroed my machine about .002 too deep. This will probably affect the life of the cutter (doubly so because I’m using FR4), but for a nice clean PCB it’s worth it.

[1] The board in the picture is cut with traces set to 25mil and clearances set to 30mil (in reality, the traces are probably a little narrower, and the clearances a little wider, because I’m deliberately cutting a little deeper). In retrospect, these are too conservative. I’ll probably go back down to ~20mil for each. I’ll also probably increase the size of the pads next time, my soldering skills aren’t good enough for those tiny pads!

The Carbide 3D bits, specifically the drill bits, are the cat’s meow. Watching it drill those tiny holes so quickly and easily was impressive.

So based on my initial run… I’m impressed, and I’m glad that I dropped a little money to buy the drill bits and PCB engraving bits.

I have a much more complex PCB project coming up. I’ll post pictures of that in a few weeks.