I’ve really been banging my head against the wall on this, please help.

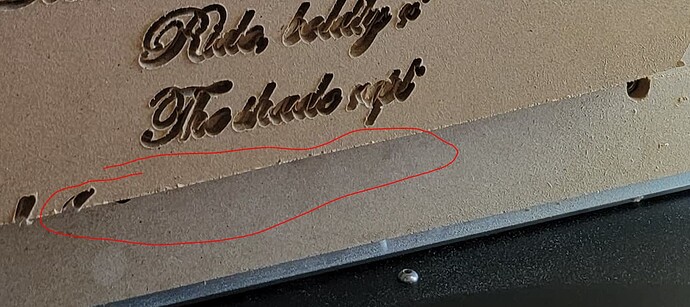

Issue summary: Text depth is inconsistent.

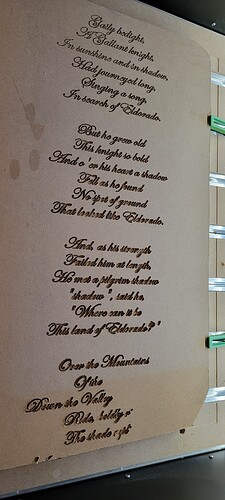

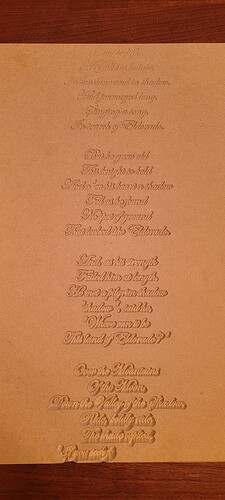

Detailed equipment//bit/material description/attempt issues: I have a shapeoko HDM. I’ve planned my spoilboard to ensure a flat work surface. I’ve used multiple plywood and MDF pieces of material. I’ve used a 60 degree V-carve and a 30 degree engraving bit. I’ve used different fonts. I also use a bitzero vs 2. Regardless of what material, bit, or text I use, when I try and carve text the depth is inconsistent the further into a project it gets. It’ll start out just fine but by the time it’s at the end it’s nearly double the depth.

Detailed design description: I’m using aspire vs 10.512. note: i’ve used carbide create and have encountered the same depth issue

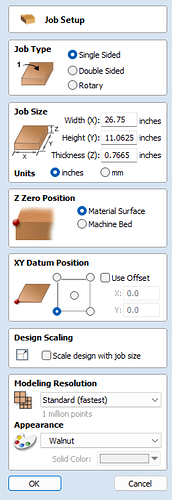

Job setup:

Text is true type, edwardian script, no bold, no italic, text alignment is center.

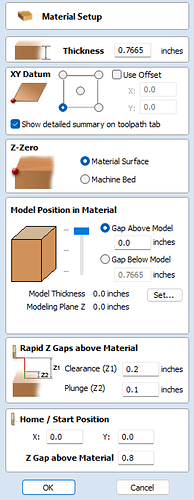

Material setup description:

I use a set of rockler calipers to measure the z thickness.

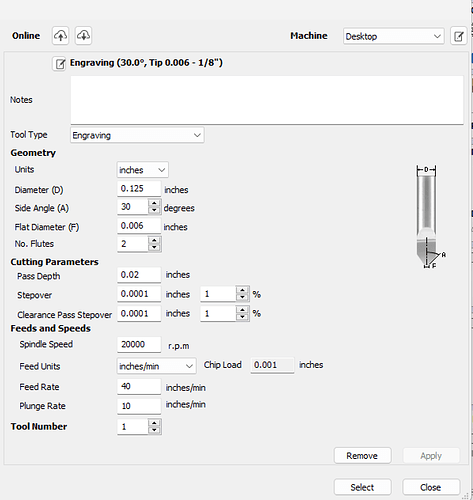

Select 2D profile toolpath, parameters below.

The 30 degree engraving bit parameters. Note: i’ve changed the cutter parameters to reflect the picture of the final product below, but i’ve also used stepover and clearance pass stepover both at the default 40% with the same outcome of inconsistent depth

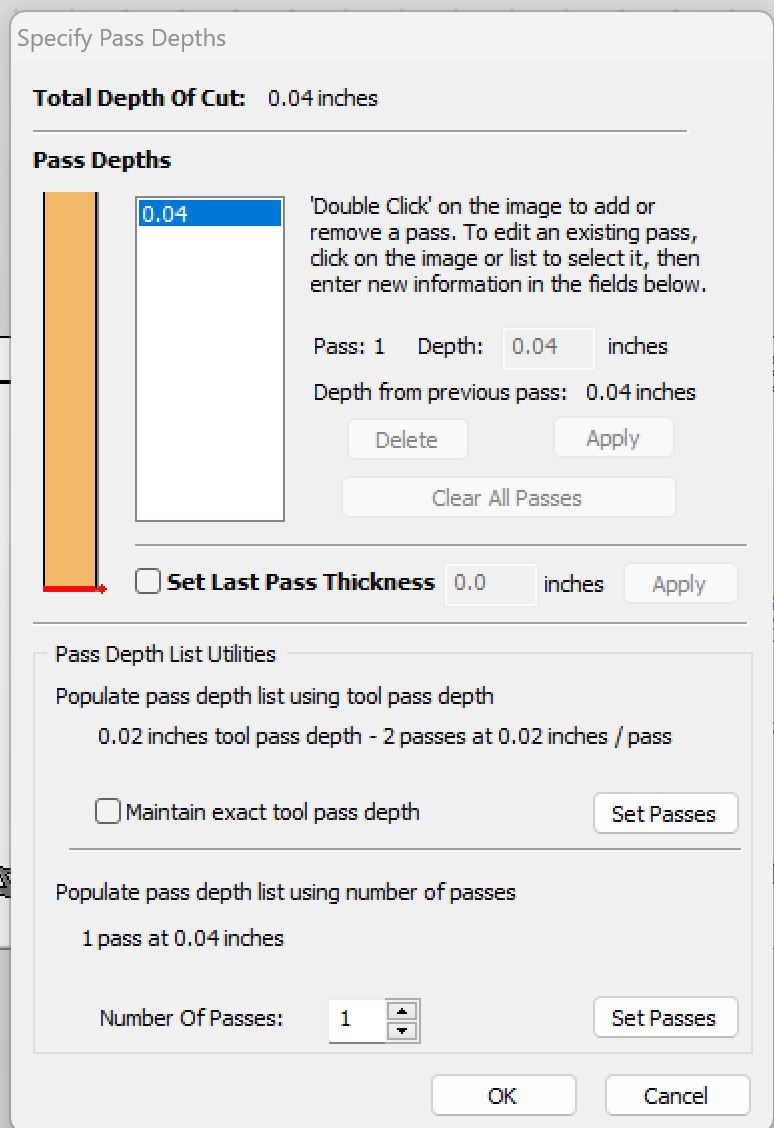

specified pass depths. note: i’ve also selected the maintain exact tool pass depth in other runs but it just created a shallow first pass at .02 with a final pass at .04 inches with the same outcome

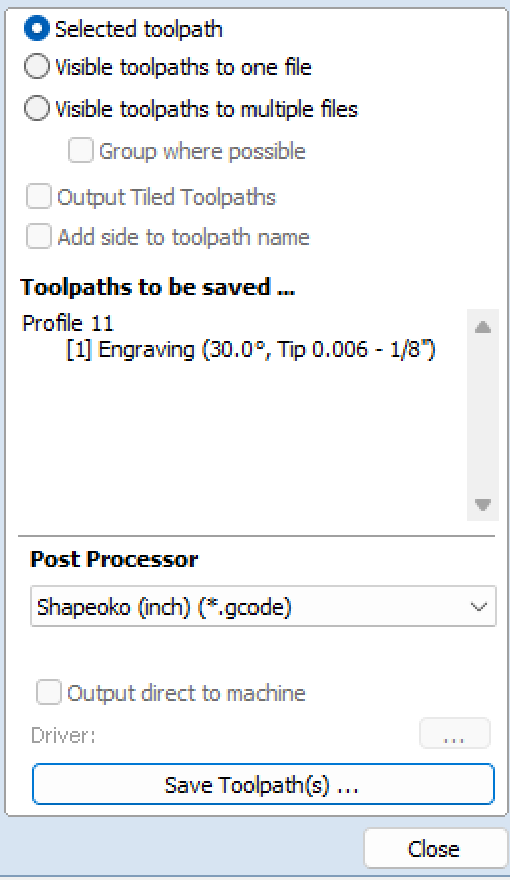

I select calculate, preview tool path, then save gcode. Ensure post processor is shapeoko (inch) (gcode).

Detailed setup description: I’ve ensure using latest Carbide Motion build 578. I’ve ensured the shapeoko HDM parameters are loaded in CM. I secure the material to the spoilboard using the standard carbide clamps, each clamp is on the same rail on each side of the material. I initialize machine, install bit and it measures the bit using the bitsetter. I load to gcode. I then jog it to the bottom left corner and using a bitzero vs two and successfully probe the bit to find the x, y axis corner. I’ll then separately probe the z function successfully. note: i’ve also attempted the manual method using a sheet of paper in separate attempts. I then hit start.

It did not completely finish the project because I stopped it due to fear of damaging the bit.

Here is a separate attempt with just a .05 cut depth parameters

The only thing I haven’t tried is planning the actual cut material. Other than that, i’m at my wits end. Please help. Thanks in advance