I posted a very short video on Instagram of the making- and spinning function of a Custom Christmas tree ornament:

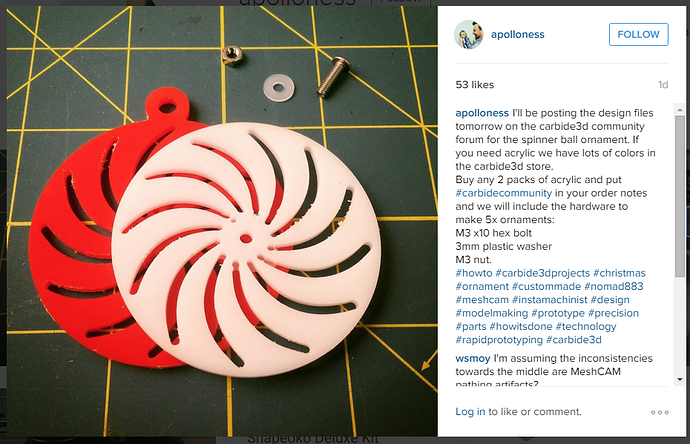

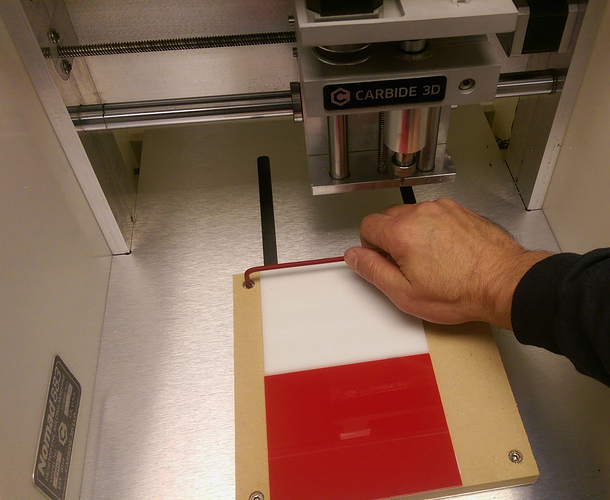

Heres a picture of the first prototype:

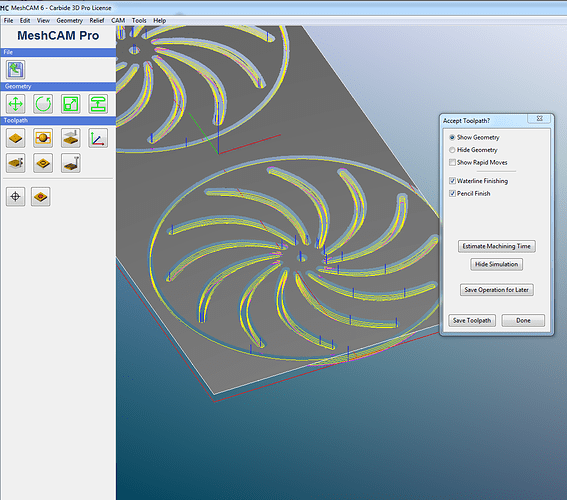

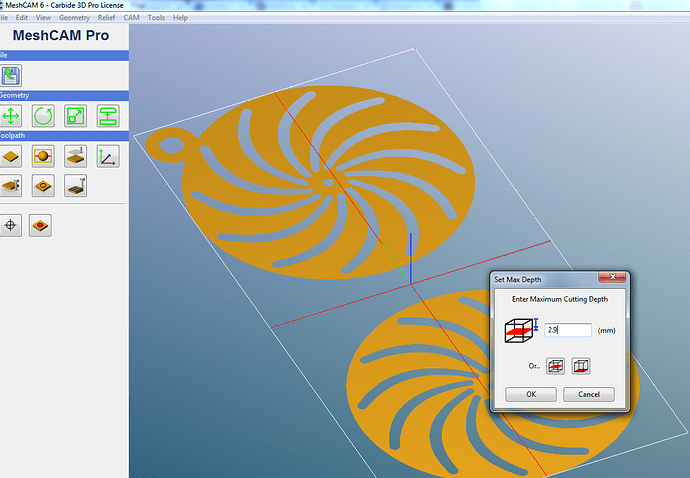

Design file is attached below as STL and MeshCAM file.

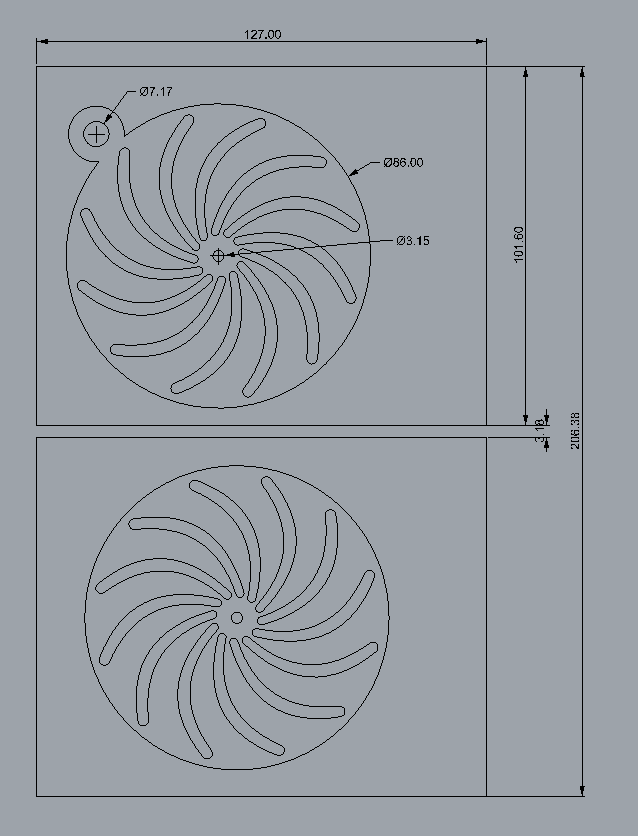

The Design file, as you can see in the first prototype parts photo, needed a little adjustment to allow the cutter to get all the way into the center of each crescent. Ive enlarged each of the crescents, and now the 1/16th endmill (#111) will reach all the way.

Some tips:

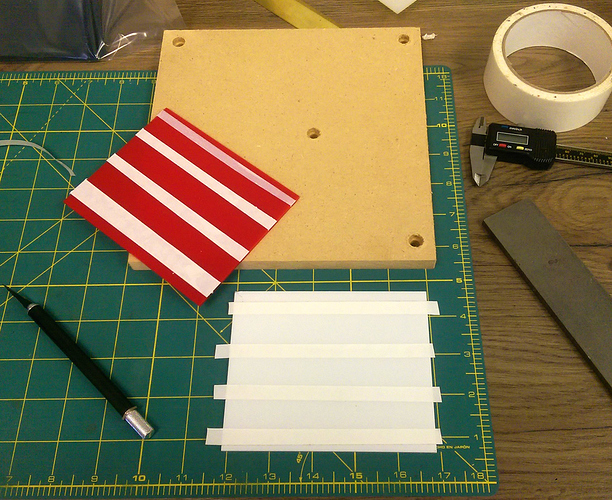

-1 Do not remove the backing film from the Acrylic, it will be much easier to peel the double stick tape with backing after cutting.

-2 Only use 1/2 strips of Double stick tape, I make thin stripes so if I do cut through to the tape, it wont be as much tape residue to remove.

-3 Place your materials with an even 3mm gap between the two on the wasteboard as shown below so you can cut both parts -but in 2 different colors- at the same time:

If you need any Acrylic, we have lots of colors in the 3mm thick and pre cut to 4" x5".

Put #CarbideCommunity in the notes and we will add the hardware for 5 ornaments.

I look forward to adding some more designs to this thread, This was a proof of concept model, and now that I know that the optical illusion of mirrored patterns works at this scale, more patterns can be created.

Design File Notes:

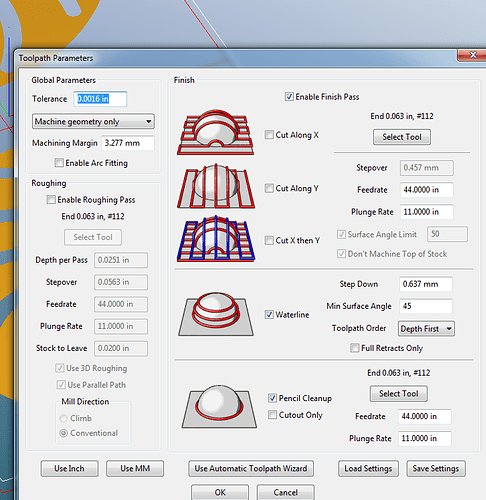

Endmill (1/16th)

I set the max depth of cut to 2.9 mm and the Zero is in the Center top of the material.

Have some fun, Happy Holidays!.

ornamentV1carbidecommunity.mcf (138.6 KB)

SpinnerV1carbide3dcomm.stl (144.3 KB)