Assembled the machine today and wanted to make my first cut. These are the steps I have performed before I got the message.

1 - Initialize, I was able to go through the entire initialization process, the machine went to the top right, then bottom right, I made a few minor adjustments to be in the center off the bit setter

2 - I secured some MDF board roughly in the center of the machine and then moved the machine to the bottom left corner, used some paper to get close to touching the MDF.

3 - I went to the zero screen and this is probably where I pressed the wrong button “zero all” / I wanted the current position to be my zero all for this job but I likely made a mistake and when pressing this button the machine went to the top right and all the way down to where the bit even caused a small scratch in the right y axis ![]()

4 - After this point, the machine won’t cooperate, I tried going through the initialize again, from the begging and tried starting over as a new machine but it just keeps throwing HM001 and HM008

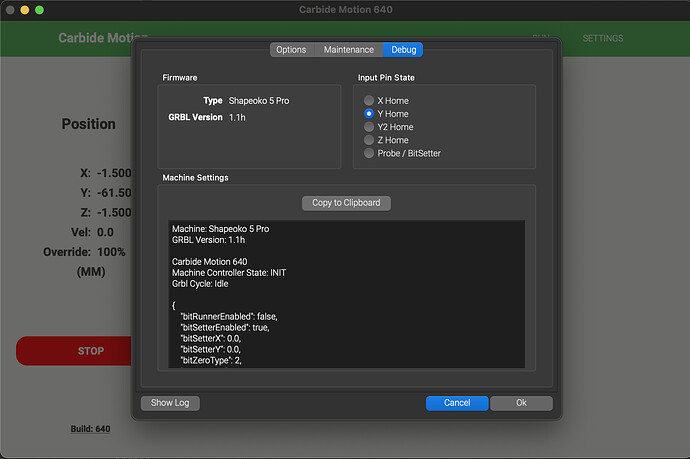

5 - In the Debug menu the Y Home is always lit and the other probes do not react to my screwdriver. The bit setter probe however reacts when pressed.

HM001: The machine could not pull off the homing switches.

This could be caused by:

-

Mechanical problems jamming a machine axis

-

A malfunctioning homing switch

https://qr.carbide3d.com/error/hm001

HM008: The machine could not pull off the homing switches.

This could be caused by:

-

Mechanical problems jamming a machine axis

-

A malfunctioning homing switch

This is equivalent to GRBL Alarm 8.

https://qr.carbide3d.com/error/hm008

Machine: Shapeoko 5 Pro

GRBL Version: 1.1h

Carbide Motion 640

Machine Controller State: INIT

Grbl Cycle: Idle

{

“bitRunnerEnabled”: false,

“bitSetterEnabled”: true,

“bitSetterX”: 0.0,

“bitSetterY”: 0.0,

“bitZeroType”: 2,

“connection”: 5,

“lastConfigSent”: 0,

“lastProbeIndex”: 0,

“lastSizeOption”: 0,

“odometer”: [

{

“cleared”: false,

“minutes”: 2.4018833333333336,

“startDate”: “2024-12-08”,

“travelX”: 2166.575988292694,

“travelY”: 5194.800048112869,

“travelZ”: 571.5759966373444

}

],

“showCarbideRouterRpm”: true,

“spindleType”: 0,

“travelX”: -1237.0,

“travelY”: -1237.0,

“travelZ”: -155.0,

“version”: 0,

“webhooks”: ,

“workOffsetX”: 0.0,

“workOffsetY”: 0.0,

“workOffsetZ”: 0.0

}

0 = 10, Step pulse, microseconds

1 = 255, Step idle delay, milliseconds

2 = 6, Step port invert, mask

3 = 0, Direction port invert, mask

4 = 0, Step enable invert, boolean

5 = 1, Limit pins invert, boolean

6 = 0, Probe pin invert, boolean

10 = 255, Status report, mask

11 = 0.02, Junction deviation, millimeters

12 = 0.002, Arc tolerance, millimeters

13 = 0, Report inches, boolean

20 = 0, Soft limits, boolean

21 = 0, Hard limits, boolean

22 = 1, Homing cycle, boolean

23 = 0, Homing dir invert, mask

24 = 500, Homing feed, mm/min

25 = 2000, Homing seek, mm/min

26 = 25, Homing debounce, milliseconds

27 = 1.5, Homing pull-off, millimeters

30 = 24000, Max spindle speed, RPM

31 = 0, Min spindle speed, RPM

32 = 0, Laser mode, boolean

100 = 80, X steps/mm

101 = 80, Y steps/mm

102 = 160, Z steps/mm

110 = 5000, X Max rate, mm/min

111 = 5000, Y Max rate, mm/min

112 = 3000, Z Max rate, mm/min

120 = 500, X Acceleration, mm/sec^2

121 = 500, Y Acceleration, mm/sec^2

122 = 500, Z Acceleration, mm/sec^2

130 = 1250, X Max travel, millimeters

131 = 1250, Y Max travel, millimeters

132 = 155, Z Max travel, millimeters

Maintenance:

Travel (km) 0.00, 0.01, 0.00, 0.04 Hours since 2024-12-08

Queue Empty