I keep getting machining errors, and I checked and found that the spindle’s axis is moving, what should I do to fix this?

The X-axis direction is okay, but there is quite a bit of error in the Y-axis direction.

It’s a recent problem, but the bolt or the nut on the shaft hasn’t been loosened, is it a bearing problem?

When a 52mm hole is processed, it almost fits in the X-axis direction, but it is processed to be about 0.2mm smaller in the Y-axis direction.

If you move X and Y by the specified distance in the test, then it moves exactly.

However, there is a problem when processing.

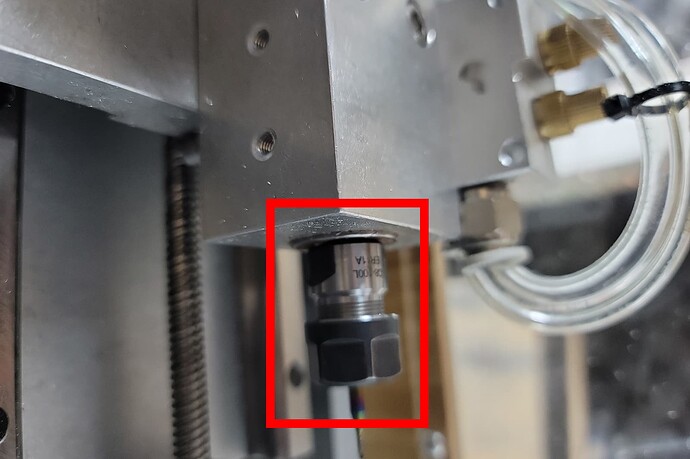

I think the problem is that the spindle shaft is not properly fixed and moves when you hold it with your hand and shake it.

Where should I repair it?

I’ve looked it up a little and I think it’s the same problem.

Contact us about this at support@carbide3d.com and we will get it worked out.

I sent you an email.

I’ll be waiting for the reply.

I sent you an email, so please check and reply.

[private email edited out]

I sent you an email, how much longer do I have to wait to get an answer?

I was able to look up your e-mail from the moderation history of your previous post.

You should have received an automated answer almost immediately.

We have a ticket open for your problem which notes that you need a new spindle. We’ll check on this and try to get you an updated status as quickly as we can.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.