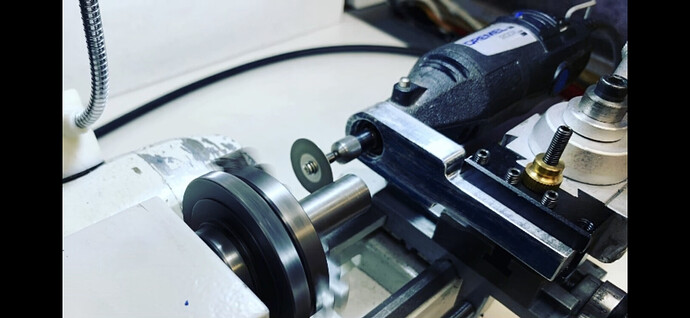

Some 3/4"-12 UNS Thread Milling to make a Dremel Lather Adapter…I need to have the ability to ID/OD Grind on my Lathe.

https://www.instagram.com/p/CMiH686jrmz/

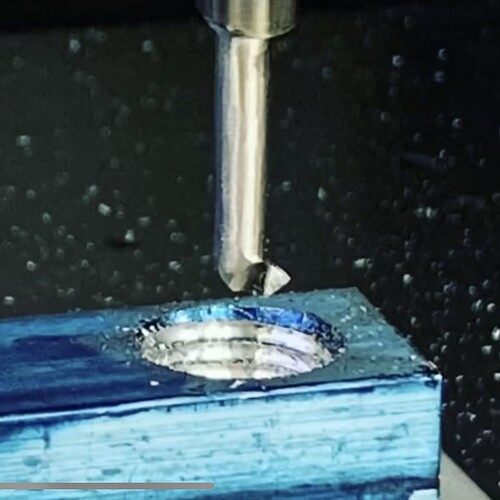

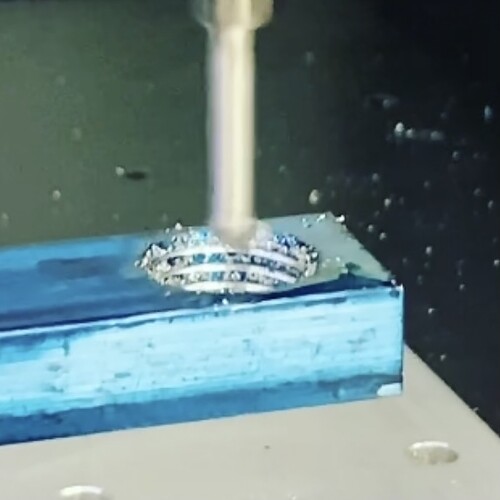

Still making my own Thread Mills. This one is from an old HSS 3/8 End Mill.

Total 12 cuts (including one spring pass)

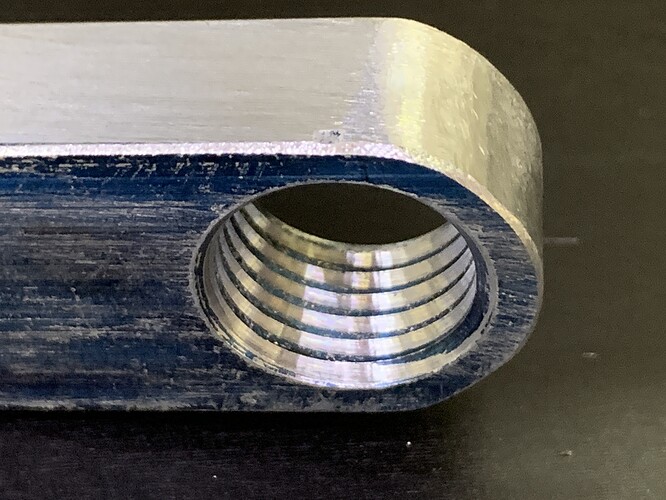

Finish Product: