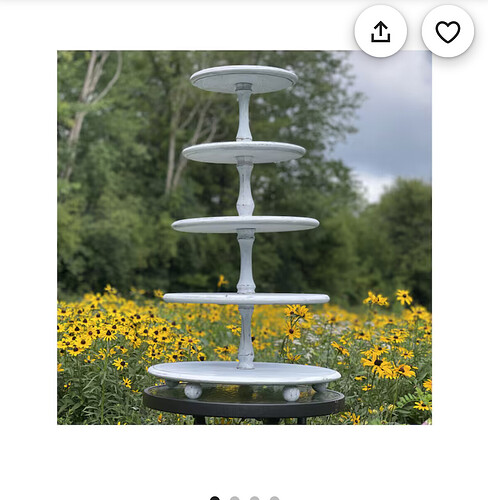

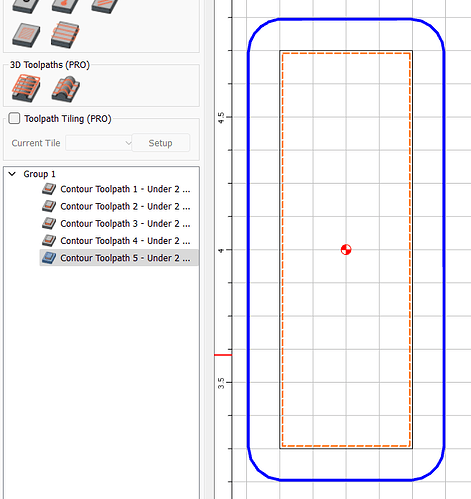

I’m constructing a 5 tier cupcake holder w/a-central support running through the rounds. I’ve found an astra coated 1/4 inch bit slowed to 100 ipm at .040 depth of cut gives a clean square mortise (1.25) I’m a bit stuck though as the through support is approx 28 inches long and the tiers are separated by six inch spacing; that’s a lot of manipulation and the possibility of breaking something is real. So while I’m trying g to sneak up on a difference between mortise and tenon widths that will allow for a snug but workable fit I thought I’d throw it out there.

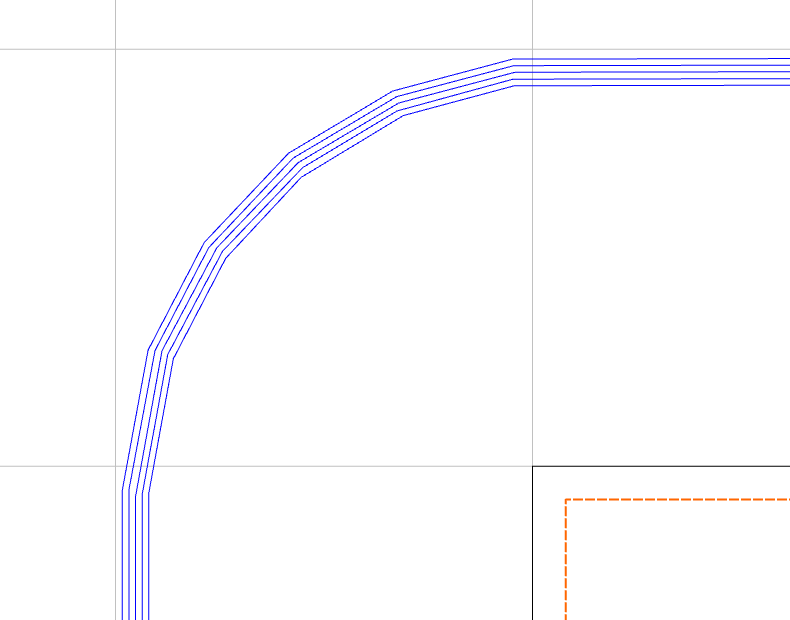

Photos showing how the cuts are turning out?

Upload the files you are currently working with?

I’m having a hard time imagining a cupcake tree with mortise & tenons ???

Picture?

But to sneak up on a dimension, make a series of cuts with different “Stock to Leave” values with a pause to measure or fit, and stop the program when it fits.

I generally find that a slip fit glue joint in most wood is about 0.010". So I would offset the vector for the tenon 0.010" on each side, 0.020" overall dimension. But then create a series of paths that leaves 0.008" to 0.000" stock. Run each path, pause & measure, or fit the other side to it, then continue until you get the fit you want.

I’ve created confusion, my special talent. I was using mortise and tenon as an attempt to describe the basic structure

I thanks Tod, I get what you’re explaining and it’s helpful for sure. I’ve created confusion though with the terms, I’m not necessarily making a mortise and tenon joint on the machine. Looking to make the through “mortises on the rounds to acclimate the 1.25 inch center support

My inclination for this sort of thing on a Shapeoko would be to make a fixture to hold the round stock vertically and machine thus.

If you wish to do this by hand there are various jigs/fixtures.